Silica Sand Processing

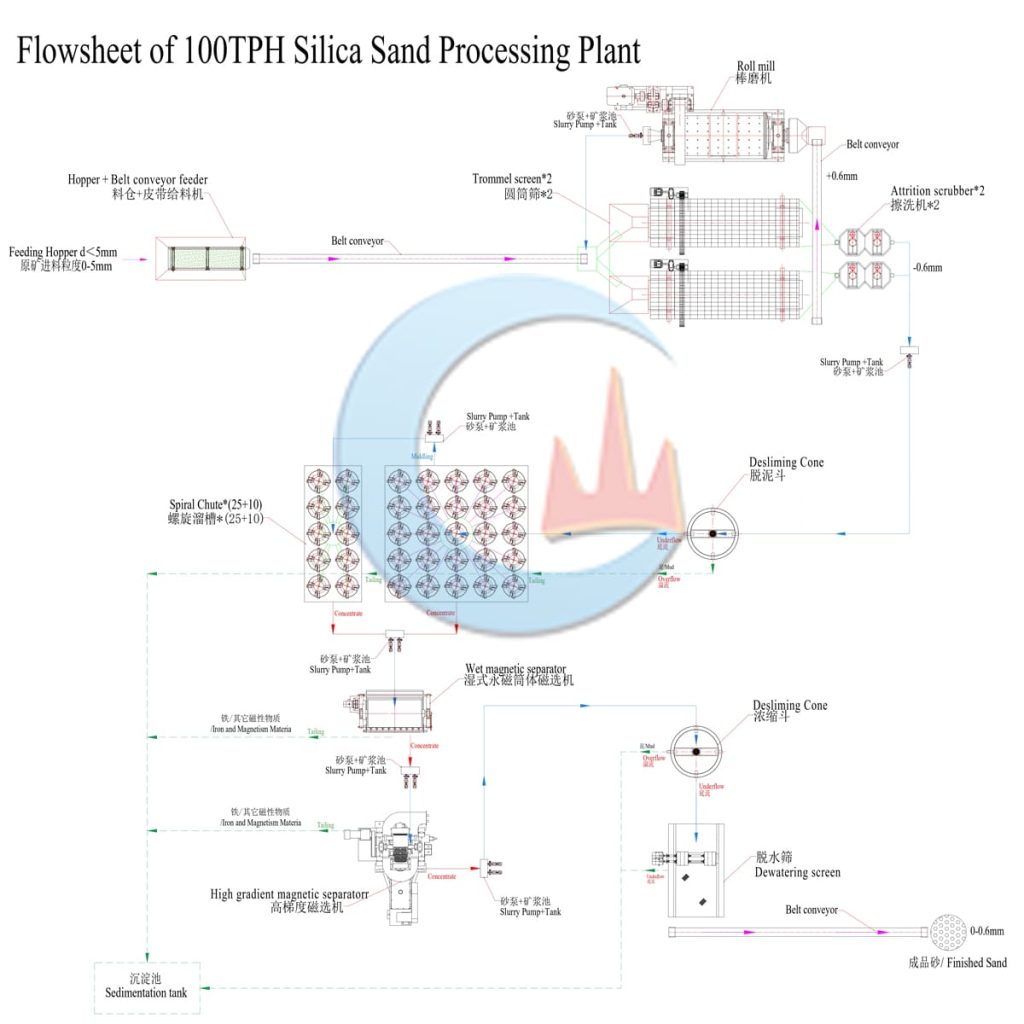

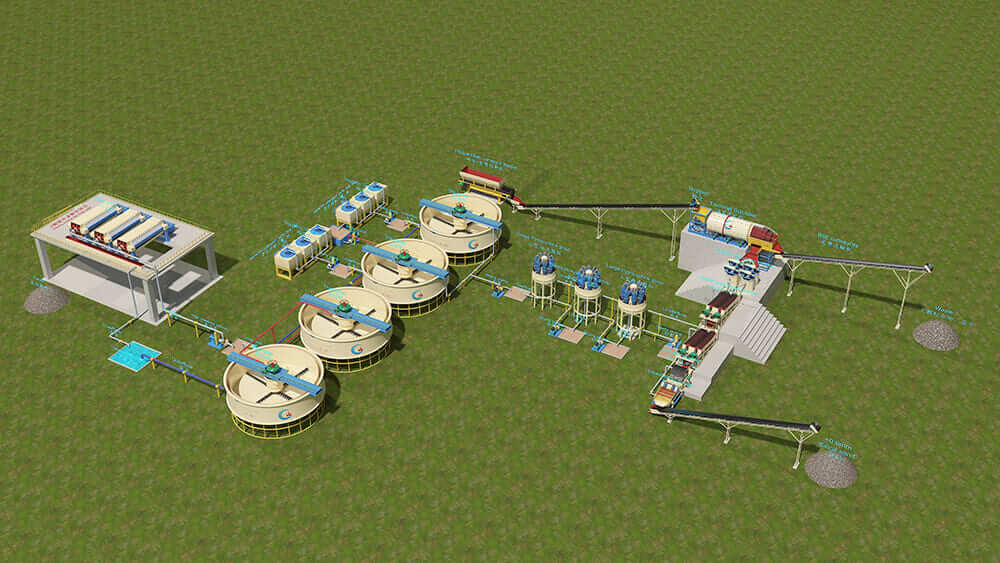

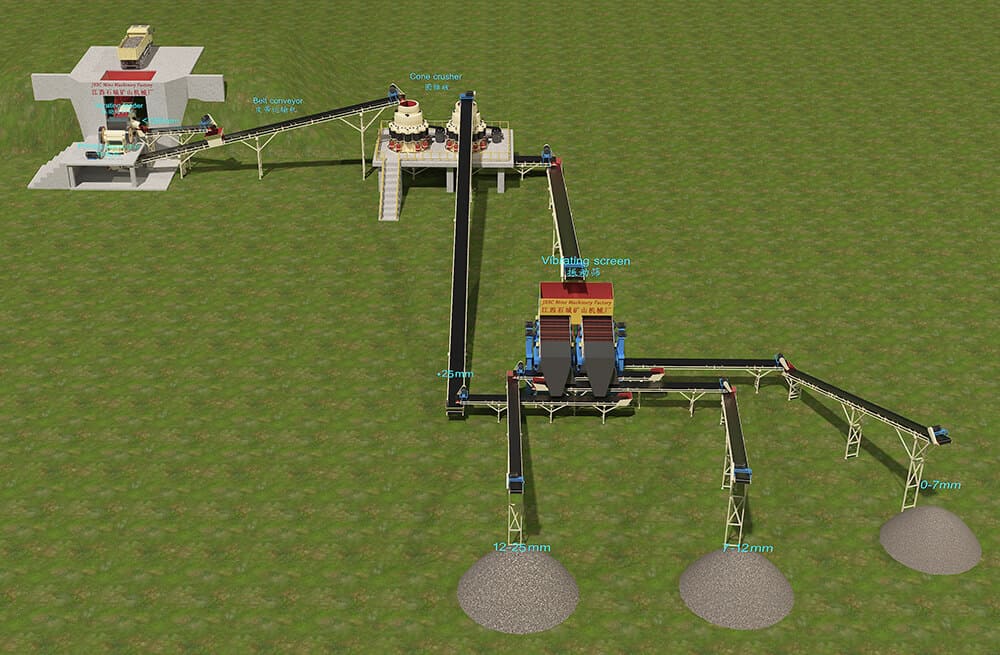

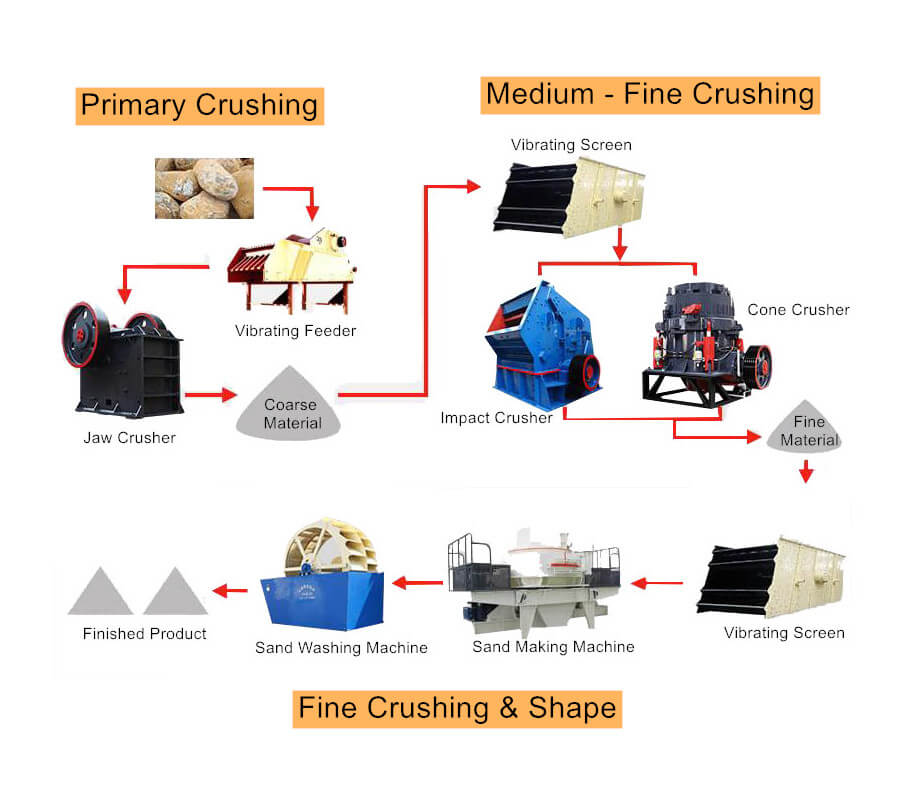

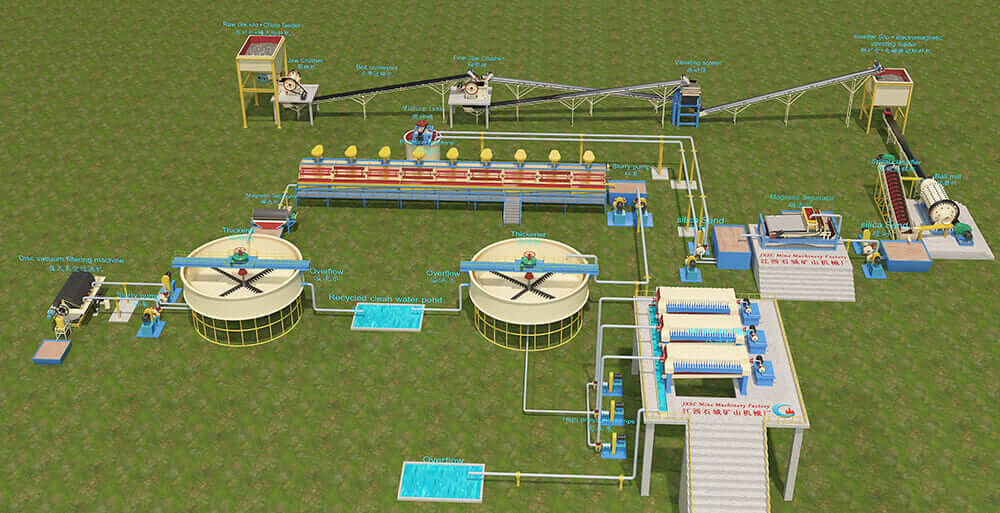

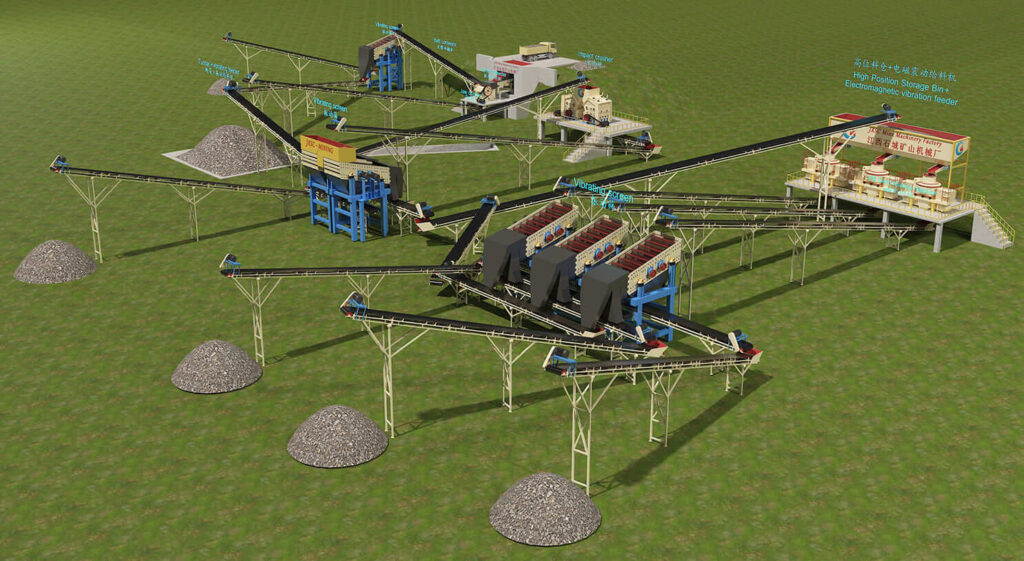

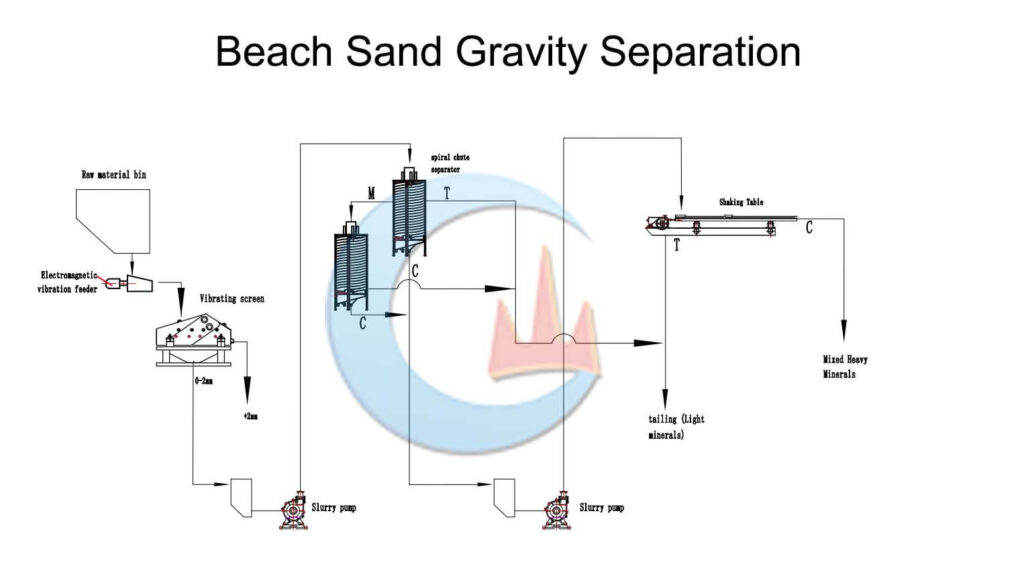

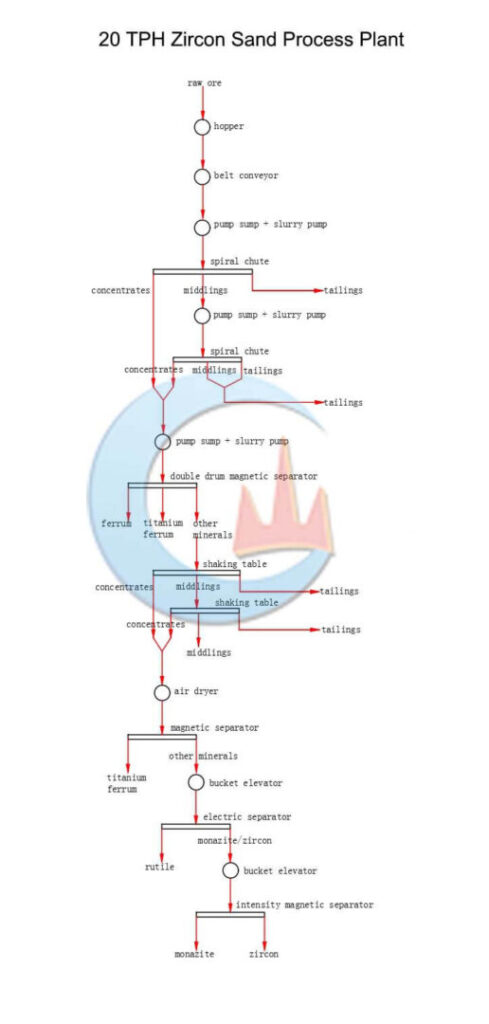

Home Silica sand processing plants are mainly aimed at removing impurities and improving the grade and particle size uniformity of silicon dioxide. Common silica sand beneficiation methods include washing, grading, scrubbing, gravity separation, hydraulic beneficiation, magnetic separation, flotation, etc. Process Consult Introduction Mineral Processing Equipment Lists Other Solutions Silica Sand Processing Plant Introduction About Silica Silica (SiO₂) […]

Silica Sand Processing Read More »