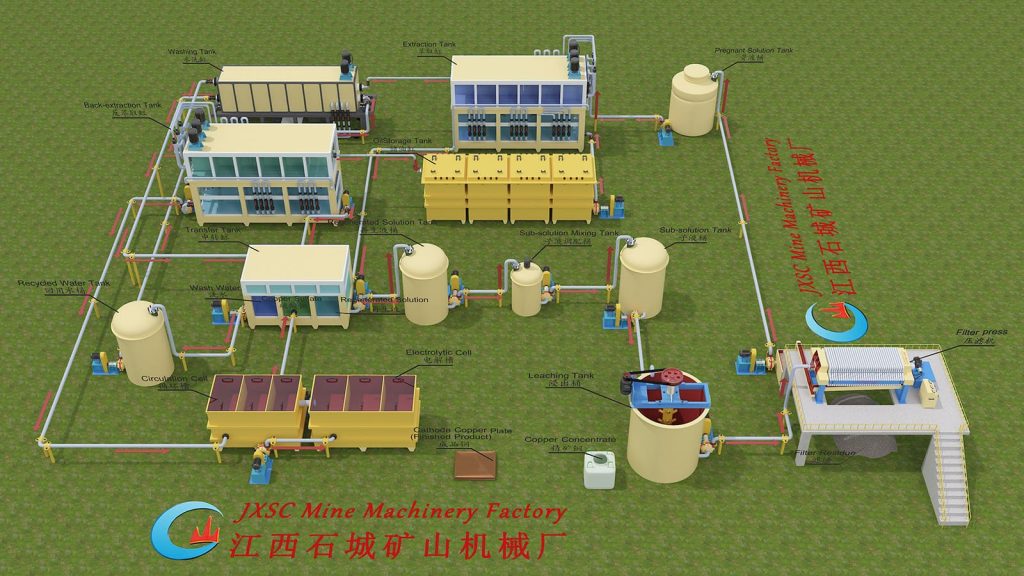

Copper Electrolysis & Electrorefining Plant

Welcome to Our Copper Electrolysis Plant Discover our cutting-edge electrolysis processes for efficient copper production and purification. Learn More Copper Electrolysis Plant Overview Our state-of-the-art copper electrolysis & electrorefining plants employ advanced technology to ensure efficient and sustainable copper production. Our process is designed to minimize environmental impact while maximizing product quality. Our Copper Plant ♥ […]

Copper Electrolysis & Electrorefining Plant Read More »