Zambia 25TPH Rock Copper Process Plant

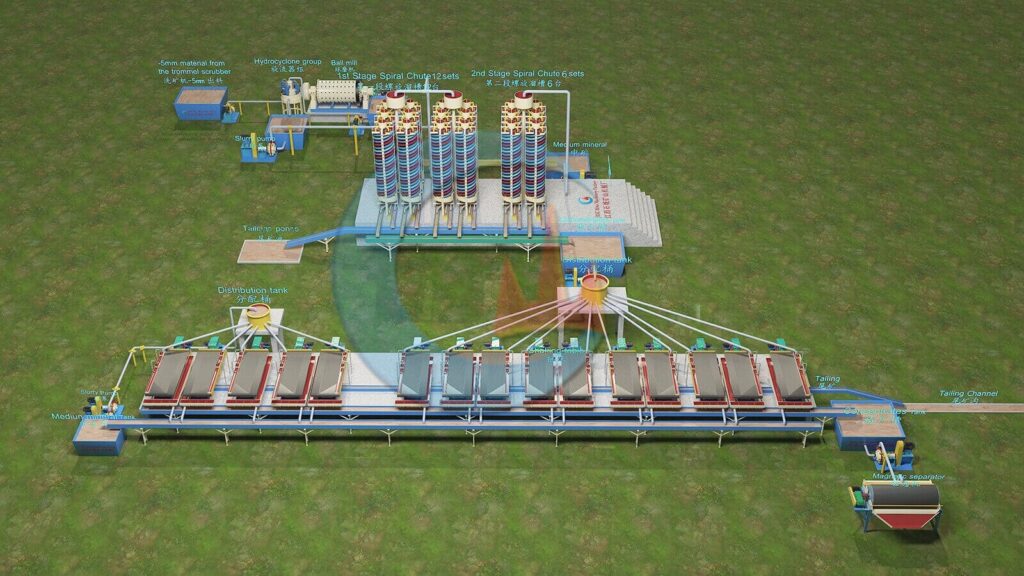

Home JXSC has provided a 25TPH copper processing plant in Zambia. We design the rock copper process plant flowchart and plant layout drawing according to the mineral ore’s conditions and offer a complete set of plant machines. We also send the engineer to the site to install and debug the machines. Help or Consult Introduction […]

Zambia 25TPH Rock Copper Process Plant Read More »