Wolframite (Tungsten) Mineral

Wolframite is the principal and primary ore mineral of tungsten and is commonly associated with the tin ore in and around granite country rocks. It consists of quartz dyke type ores and veinlet tungsten ores. And the mineral processing of Wolframite is a combined separating technology that mainly use gravity separation.

Wolframite(Tungsten) Mineral Mining Process

Introduction

About Wolframite Ore

Wolframite is a black or brown mineral which is the chief ore of tungsten. It consists of a tungstate of iron and manganese. The wolframite ore has a high depletion rate, low grade, coarse grain size, high density, low hardness, easy mud formation, and deep color, which is mainly extracted by the gravity separation process.

Mineral Processing

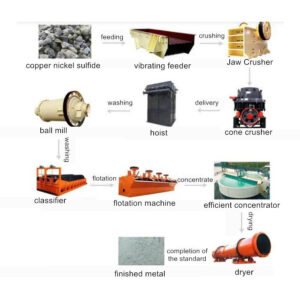

Wolframite(Tungsten) Ore Processing

Pre-enrichment

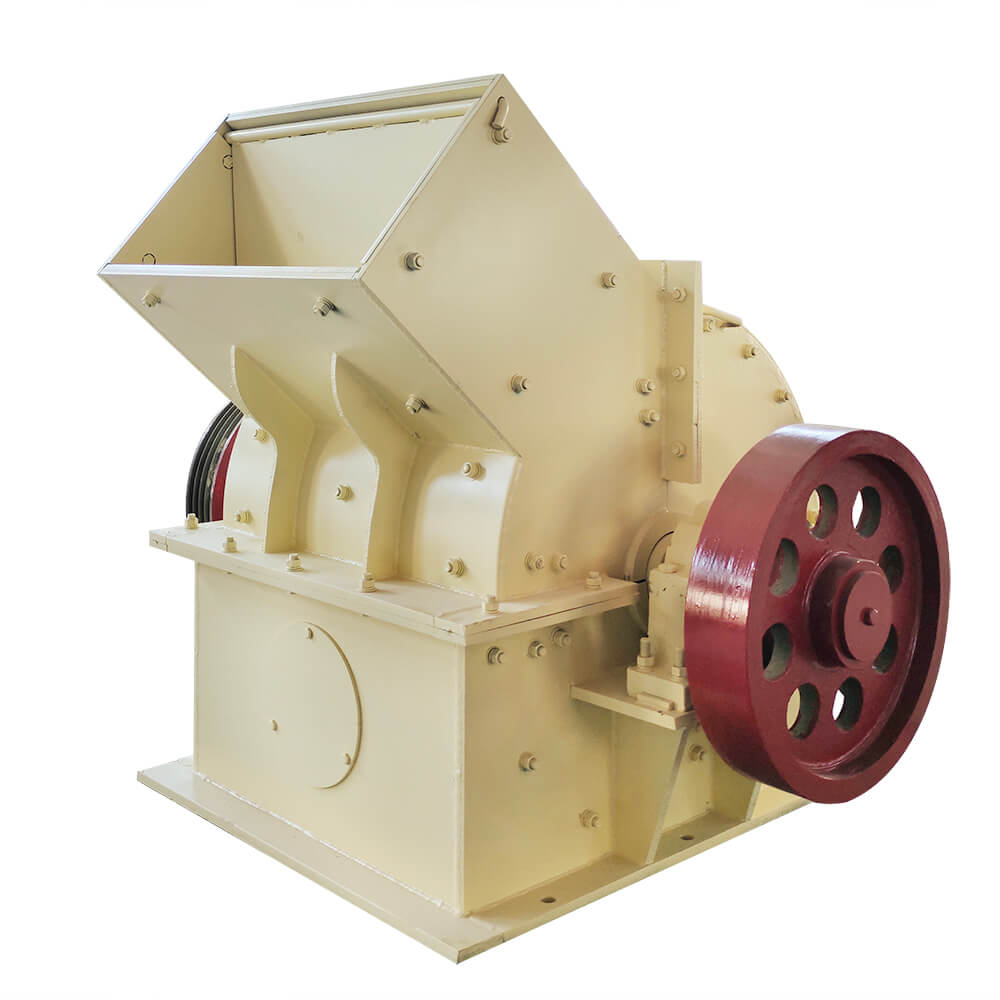

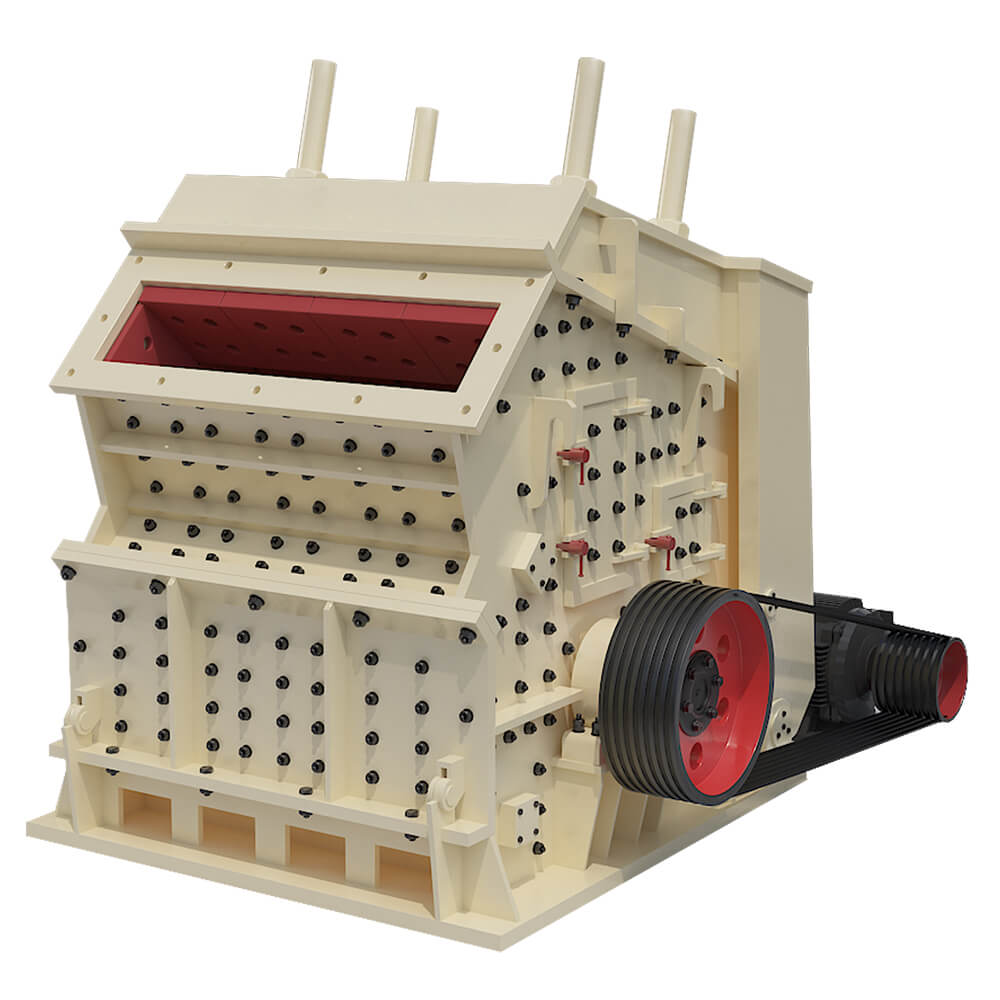

The dilution ratio of wolframite mining is generally around 80%. The amount of surrounding rock in the ore is large and easy to distinguish with wolframite-containing rock. Pre-select the waste rock increases the beneficiation processing capacity and efficiency, and reduces the rock crusher wear. After the pre-enrichment, the materials go through the process of washing.

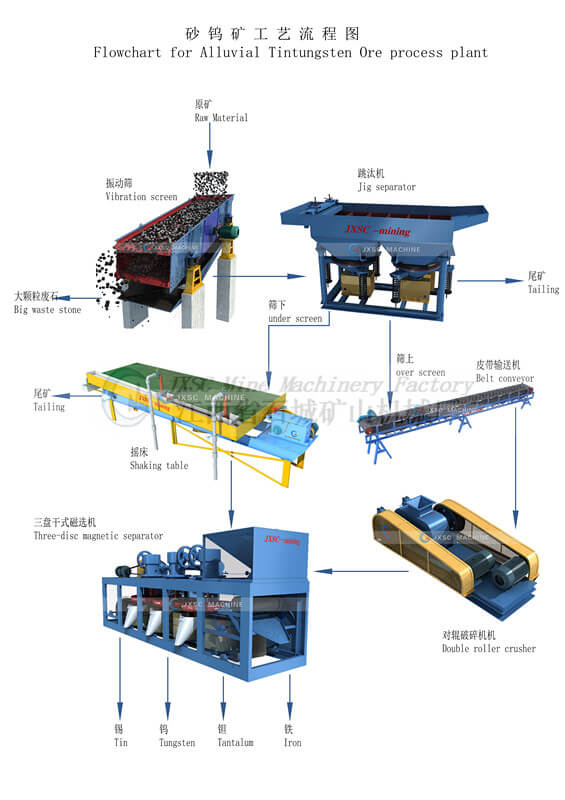

Gravity separation

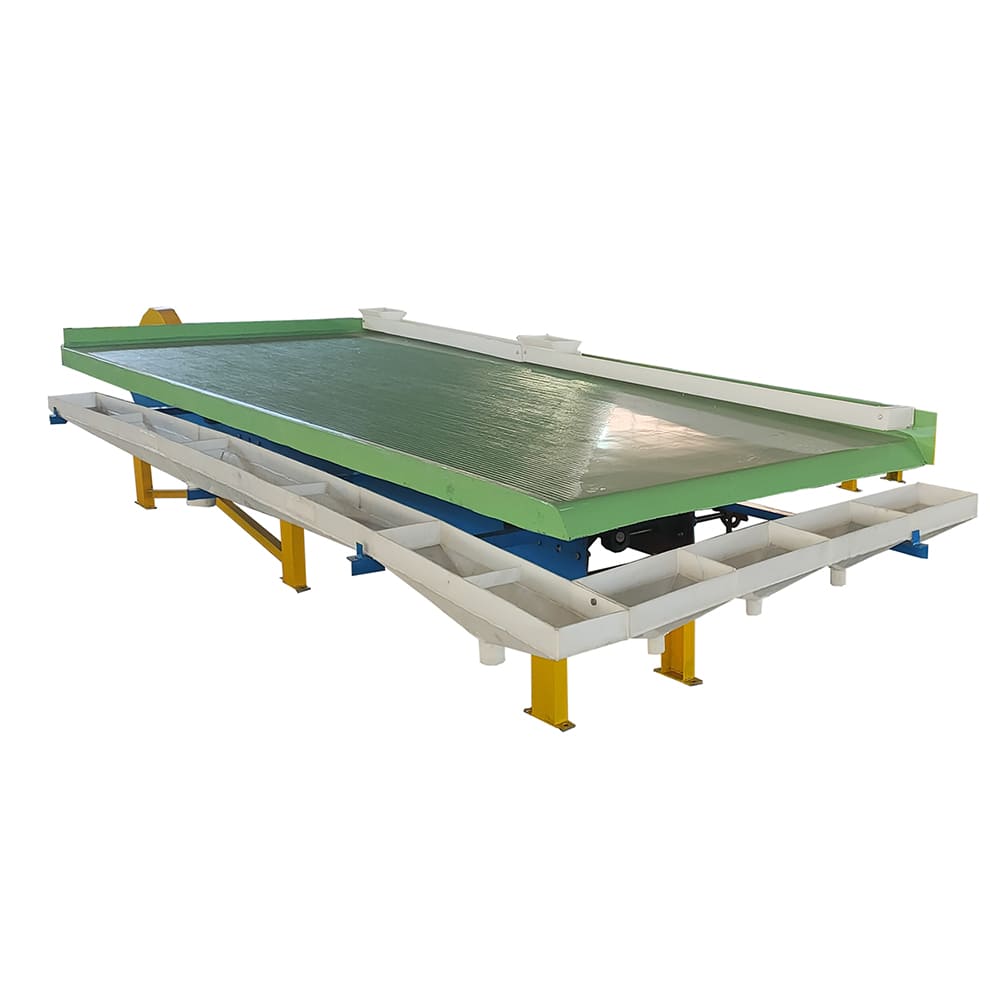

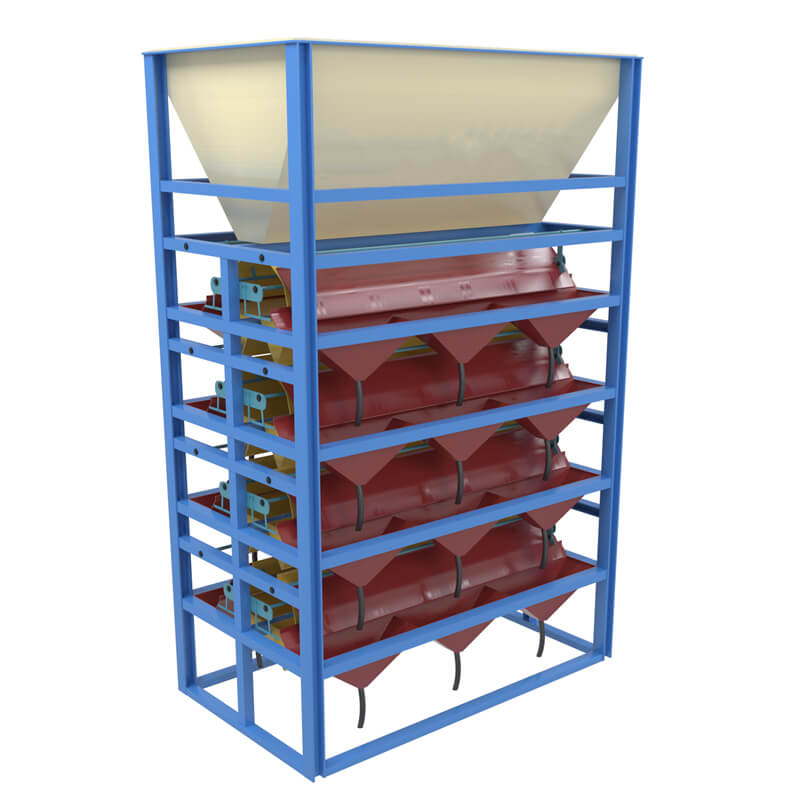

At this stage, we grade and sort the minerals. Usually, the jig concentrator and shaker table recover the coarse particle wolframite.

Fine wolframite slime concentration

Fine wolframite slime includes primary and secondary slime, which accounts for about 10% of the original ore. The tungsten grade is higher than the original ore, the grade is 14% to 15%. Extracting tungsten from slime is an important method for improving the tungsten recovery rate.

Wolframite slime concentration machines have shaker tables, centrifugal concentrators, belt chute, flotation, and magnetic separation. The fine mud recovery rate has increased from 10% ~ 50% to 60%~70%.

Supplementary

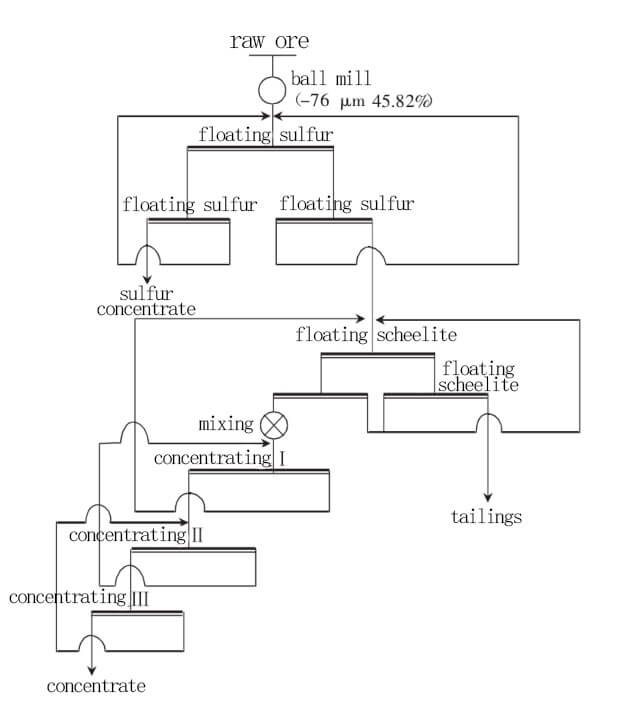

Scheelite flotation process

The scheelite accounts for 97.72% of the total amount of tungsten.

The sulfide minerals mainly include pyrite, stibnite, bismuth-copper-silver-ore, stibnite, a small amount of galena, sphalerite, beryllium ore, arsenic, and bismuth.

The gangue minerals are mainly quartz, mica, and a small amount of calcite, apatite, etc.

Result

The tungsten concentration was 1.09%. WO 3 grade was 71.78% and the recovery was 90.19%