Limestone Crushing Process

The limestone crushing process involves several stages, each with specific machinery and equipment. The typical limestone crushing process is Primary Crushing -> Secondary Crushing -> Screening -> Conveying -> Storage

Limestone Crushing Process

Introduction

About Limestone

Limestone is a sedimentary rock composed primarily of calcium carbonate (CaCO3) in the form of the mineral calcite or aragonite. It is a kind of stone widely found in nature. Limestone can be directly processed into stone using crushing equipment and fired into quicklime. Quicklime absorbs moisture or adds water to become hydrated lime. The main component of hydrated lime is calcium hydroxide. The hydrated lime is prepared into lime slurry, lime paste, etc., as coating materials and brick adhesives.

Limestone can have various colors, ranging from white and gray to beige and even black, depending on the impurities present and the specific mineral composition.

Limestone Use

- Construction: Limestone is a popular material used to construct buildings, roads, and other structures.

- Agriculture: It is used as a soil conditioner to raise the pH of acidic soils, making them more suitable for plant growth.

- Industry: Limestone is a key ingredient in cement production and is also used in various industrial processes, such as in the manufacturing of glass, paper, and steel.

- Decorative purposes: Limestone is often used as a decorative stone in landscaping and architecture due to its natural beauty and versatility.

- Water treatment: Crushed limestone is used in water treatment processes to neutralize acidity and remove impurities.

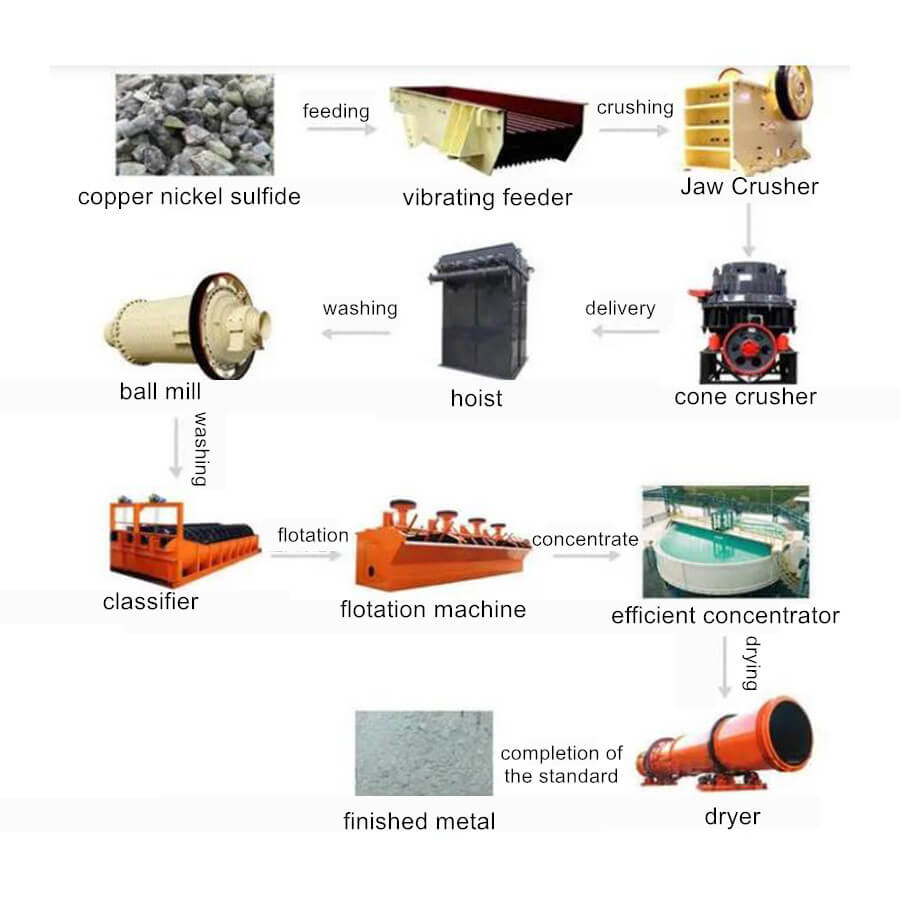

Mineral Processing

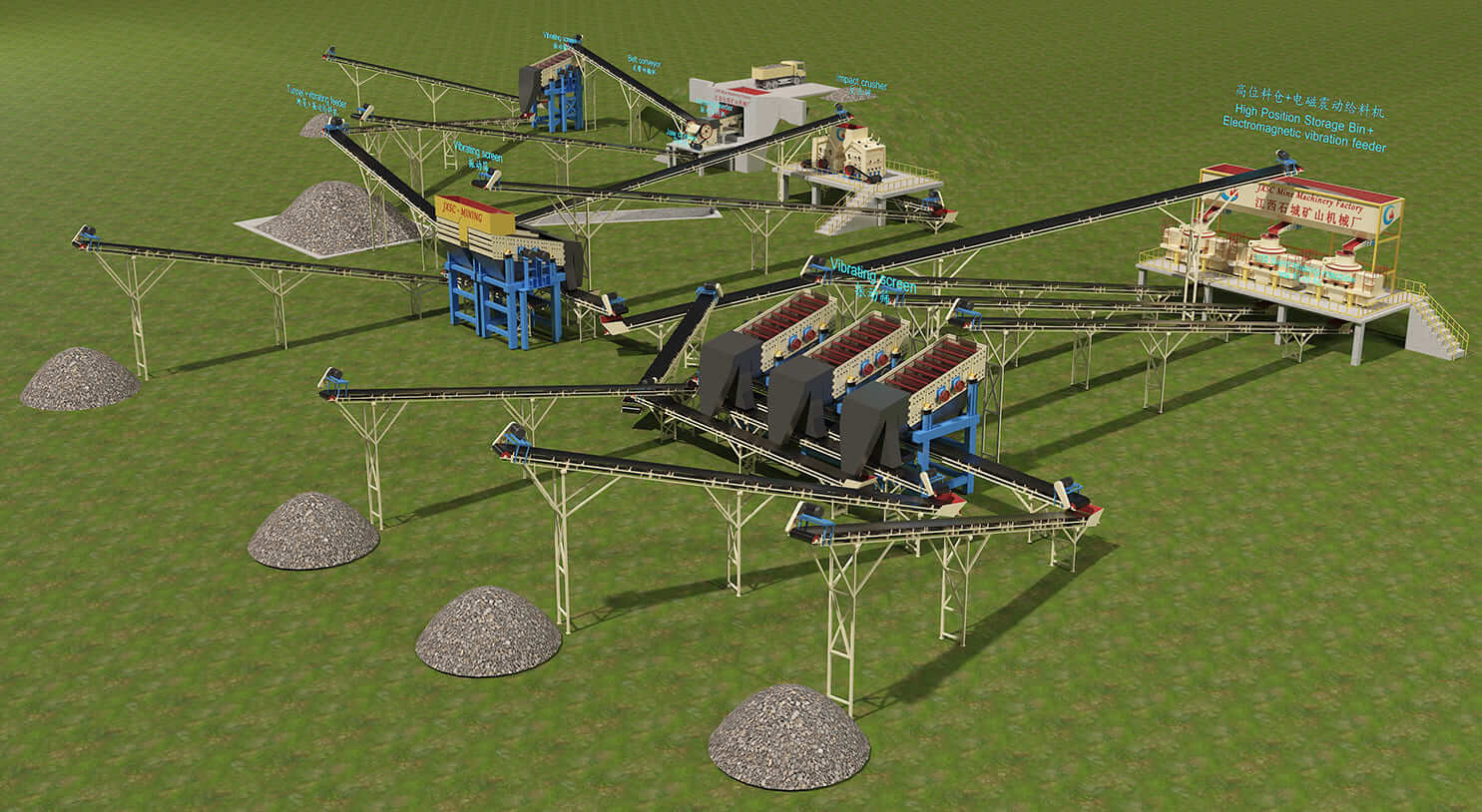

Limestone Crushing Plant

500TPH Complete Limestone Crushing Plant

Philippines 200TPH Limestone Crushing Plant

400TPH Limestone Crushing Plant – Sand Making

Limestone Processing

Mining and Quarrying

The process begins with limestone extraction from a quarry or mine. This may involve drilling, blasting, and other methods to break the limestone into manageable sizes for further processing.

Primary Crushing

The extracted limestone is transported to the primary crusher, usually a jaw crusher. This crusher reduces the large chunks of limestone into smaller particles.

Secondary Crushing

After primary crushing, the crushed limestone is further reduced in size by secondary crushers. Common secondary crushers include cone crushers, impact crushers, or gyratory crushers.

Screening

The crushed limestone is screened to separate different sizes of particles. This step ensures that the final product meets the required specifications. Oversized or undersized particles may be returned to the crushing process for further reduction.

Conveying

Conveyors transport the crushed and screened limestone to different processing plant or storage facility stages.

Storage

The crushed limestone may be temporarily stored in stockpiles or silos before being used or further processed.

Dust Collection and Environmental Controls

Limestone crushing plants often include measures to control dust emissions and other environmental impacts. This may involve the use of dust collectors and other pollution control technologies.