Kaolin/Kaolinite Processing

Typical kaolin beneficiation and purification processes include gravity separation, magnetic separation, flotation, leaching, chemical bleaching, and roasting. Different beneficiation methods are suitable for different kaolin ores, and the specific beneficiation method needs to be determined according to the nature and use of the ore.

Kaolin Mining Processing

Introduction

About Kaolin Clay

Kaolin, also known as kaolinite or ceramic clay, is a mineral primarily extracted from kaolinite ore. It is named after the hill in China (Kao-ling) from which it was mined for centuries. Kaolin contains primarily aluminum silicate and is often represented by the chemical formula Al2Si2O5(OH)4. It is usually white or light gray and has a fine granular texture.

Kaolin is widely used to produce ceramics, paper, rubber, and refractory products. It can also synthesize zeolite molecular sieves and fillers for daily chemical products. In the context of ore, kaolin deposits are often extracted from the Earth through mining. The extracted kaolin ore is then processed to remove impurities and refine the material for specific industrial uses.

Mineral Processing

Kaolin Purification

Kaolin often contains harmful impurities like iron, organic matter, and dark substances. These harmful impurities will cause kaolin to show different colors and affect its whiteness. Therefore, we must remove impurities from kaolin before use. The common kaolin purification methods include the following items.

Kaolin gravity separation

The gravity separation and purification process mainly uses the density and particle size differences between kaolin and gangue minerals to remove light organic matter and high-density impurities containing elements such as iron, titanium, and manganese to purify kaolin.

Centrifugal concentrators are usually used to remove high-density impurities. The hydrocyclone group can also complete the washing and screening operations in selecting kaolin. It can not only achieve the purpose of washing and classifying but also remove some impurities, which have good application value.

Kaolin magnetic separation

The magnetic separation process removes weak magnetic dyeing impurities such as hematite, siderite, pyrite, and rutile from kaolin. For highly magnetic minerals such as magnetite and ilmenite or iron filings mixed during processing, it is more effective to use magnetic separation to separate kaolin. There are two main methods for weakly magnetic minerals: roast them first to turn them into strongly magnetic iron oxide, then perform magnetic separation; the other is to use high-gradient strong magnetic separation to do the magnetic separation. The magnetic separation method effectively solves the problem of developing and utilizing low-grade kaolin with no commercial mining value due to high iron ore content. The superconducting magnetic separator has high field strength, energy saving, high productivity, etc., and can be directly processed in Kaolin clay, which contains more impurities. However, obtaining high-grade kaolin products using only a single magnetic separation method is difficult. Other processes, such as chemical treatment, are also required to further reduce the iron content in kaolin products.

Kaolin flotation

The flotation purification process can effectively remove iron, titanium, and carbon impurities in kaolin, enabling the recovery and reuse of low-grade kaolin resources such as coal-based kaolin. Kaolin particles are finer and more difficult to float than gangue minerals. Therefore, the kaolin flotation purification process mainly uses reverse flotation to achieve better impurity removal effects, such as reverse flotation for carbon removal, desulfurization, and iron removal. Kerosene is used as a collector, pine alcohol oil is used as a foaming agent, and water glass is used as an inhibitor. The flotation purification process is mostly used to treat raw kaolin ore with more impurities and lower whiteness to utilize low-grade kaolin resources comprehensively.

Kaolin chemical leaching

Certain impurities in kaolin are selectively dissolved through leaching agents such as sulfuric acid, hydrochloric acid, and nitric acid to remove impurities. This method can remove hematite, limonite, siderite, etc. from low-grade kaolin.

Kaolin chemical bleaching

Impurities in kaolin clay are oxidized into soluble substances through bleaching and then washed and removed to improve the whiteness of kaolin clay products. However, the cost of chemical bleaching is relatively high and is usually used for kaolin concentrates that require further purification after impurity removal.

Kaolin roasting and purification

By utilizing the difference in chemical composition and reactivity between impurities and kaolin, magnetization roasting, high-temperature roasting, or chlorination roasting is performed to remove iron-containing impurities, carbon-containing impurities, sulfides, and other impurities in kaolin. This method can improve roasted products’ chemical reaction activity, improve kaolin’s whiteness, and obtain high-grade kaolin products. However, the disadvantage of roasting and purification is that it consumes a lot of energy and quickly causes environmental pollution.

Kaolin Process Plant

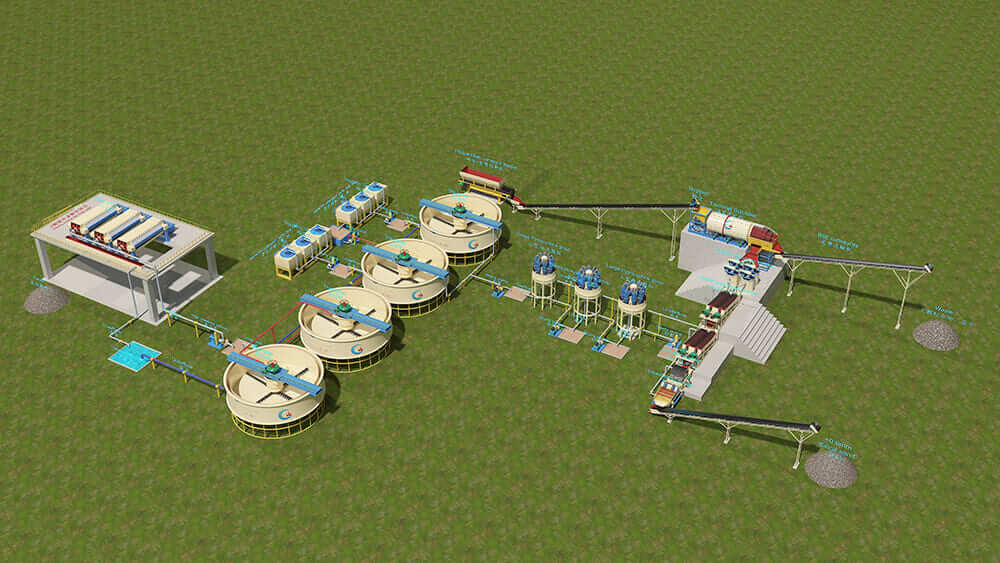

100TPH Kaolin Process Plant

- Raw ore is unloaded to the hopper and belt conveyor feeder, and then ores are transported to the rotary scrubber by belt conveyor.

- After washing and screening by the rotary scrubber, it will get 0-5mm slurry, entering attrition scrubbers, and more than 5mm of materials will go to the waste pile.

- After washing by attrition scrubbers, the slurry will go to spiral sand washing machines and wheel sand washers.

- The overflow from sand washing machines will be collected in a slurry tank and pumped to hydrocyclone sets for classifying the particles three times.

- The overflow from the third hydrocyclone set will enter 1st and 2nd thickeners for sedimentation.

- The underflow from thickeners will be pumped to magnetic separators to remove the iron and magnetism materials.

- The concentrates from magnetic separators will be pumped to the 3rd and 4th thickeners for settling again. The underflow from the 3rd and 4th thickeners will be pumped into the filter press for dehydration under pressure until we get the final product.

- The underflow from hydrocyclone sets will flow back to the sand washing machine, the sand will be pushed and dehydrated by the dewatering screen.