Hard Rock Gold Mining

Compared with placer gold, rock gold ore has higher gold content and mining value, but the beneficiation process of rock gold ore is much more complicated than that of placer gold ore. Rock gold mines mostly use the flotation and cyanidation processes according to their characteristics.

Rock Gold Mining Process

Introduction

About Hard Rock Gold

Rock gold is also called mine gold or alloy gold. Most of the gold mines are deposited and accumulated by the hot springs gushing underground through the thin cracks of the rock and are often sandwiched with quartz in the cracks of the stone. Rock gold is mainly associated with other metals, including gold, silver, platinum, zinc, and other metals. It calls them alloy gold before extracting other metals. Rock gold is produced in different mines and contains various components of other metals. Therefore, the fineness varies, generally between 50% and 90%.

The gold is hidden in the quartz veins in the rock. People need to find the gold-bearing rock first, mine the ore, crush and ball mill, and then use the gravity beneficiation or flotation method to purify the gold after the gold becomes single gold.

Mineral Processing

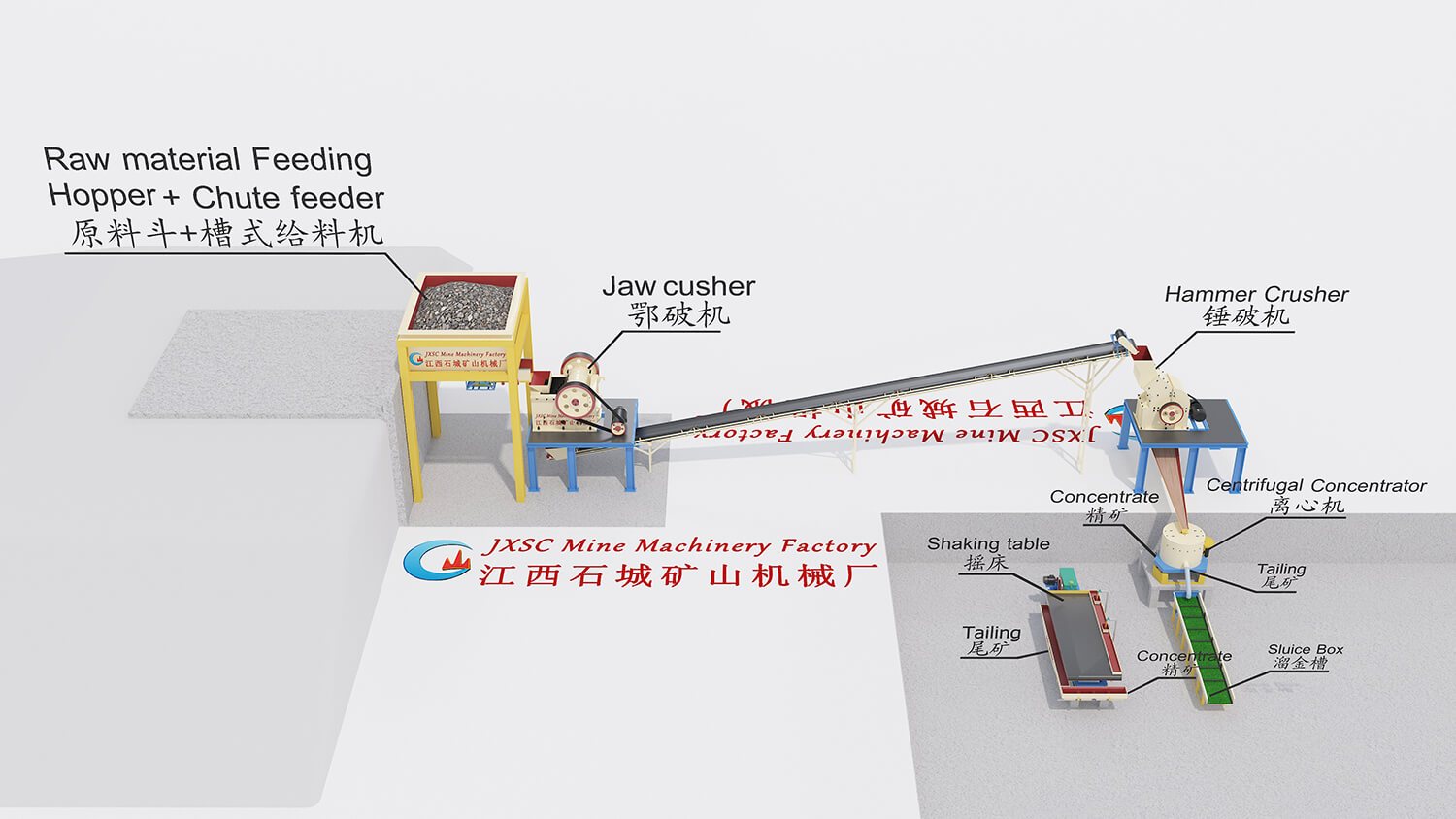

Hard Rock Gold Mineral Process

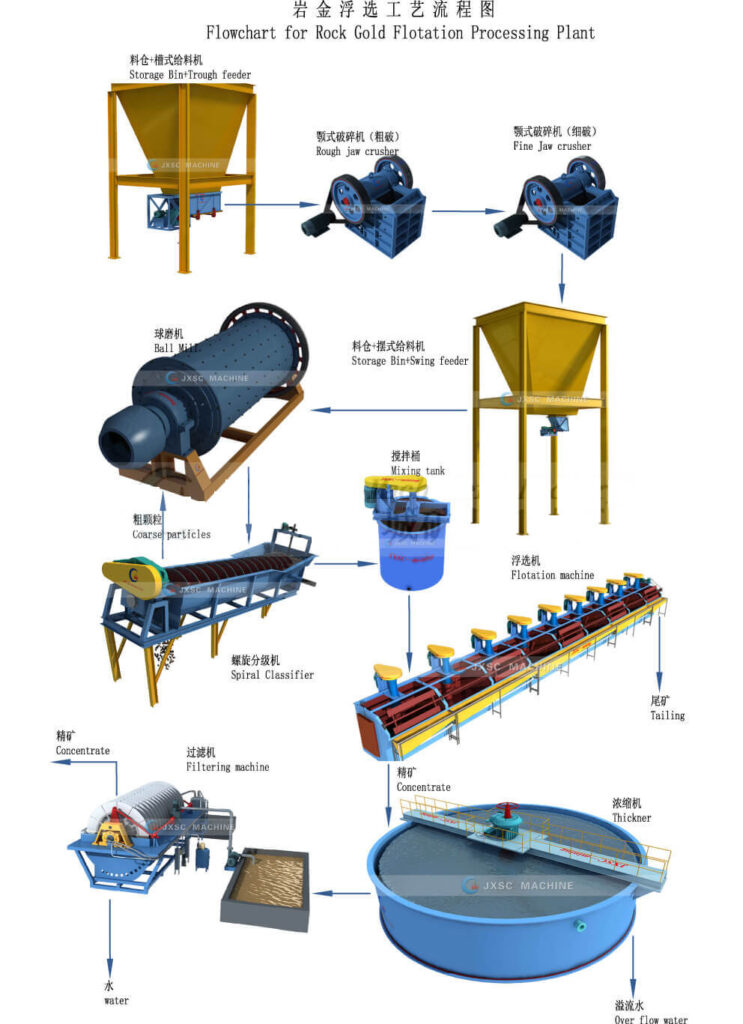

1. Rock Gold Ore Flotation Process

Flotation is used in gold beneficiation plants to treat rock gold ore and gold-bearing sulfide minerals with high float-ability. The flotation process can enrich gold into sulfide minerals to the maximum extent, and the tailings can be directly mixed with mercury or cyanidated for gravity separation. It’s with low beneficiation cost.

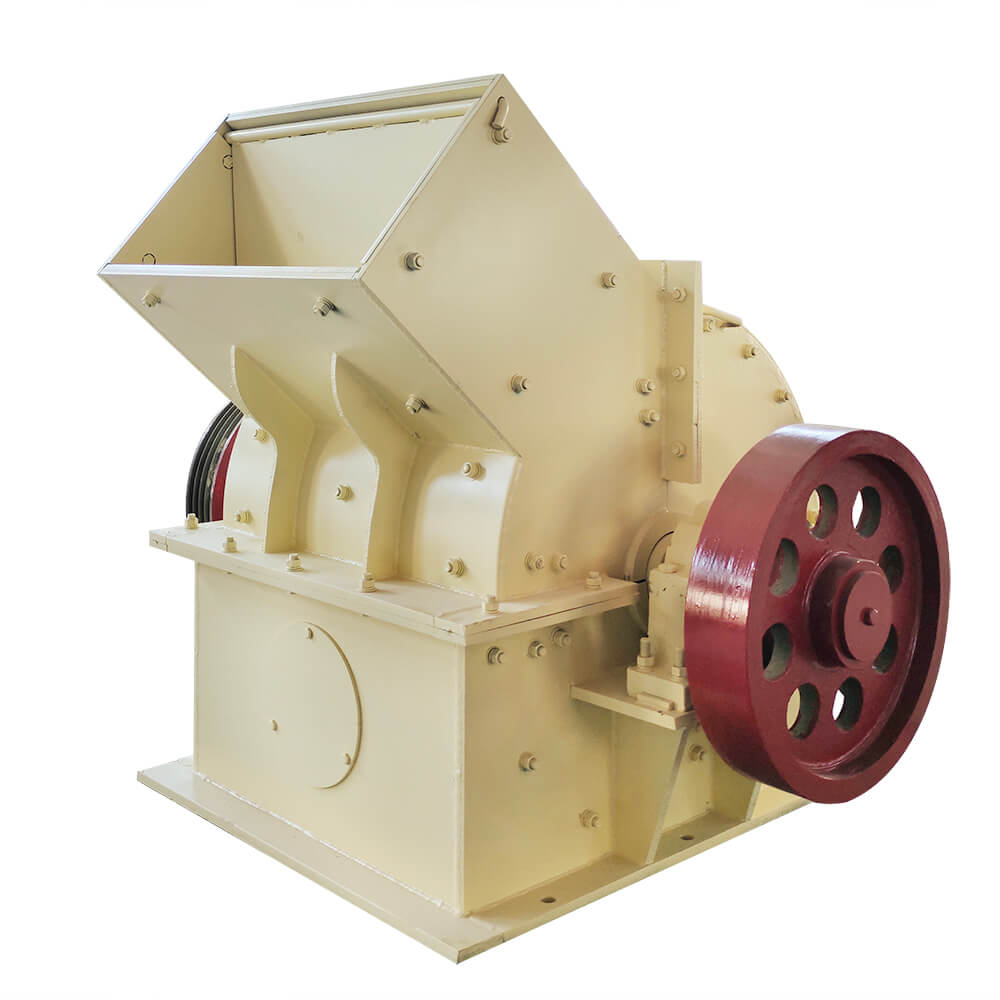

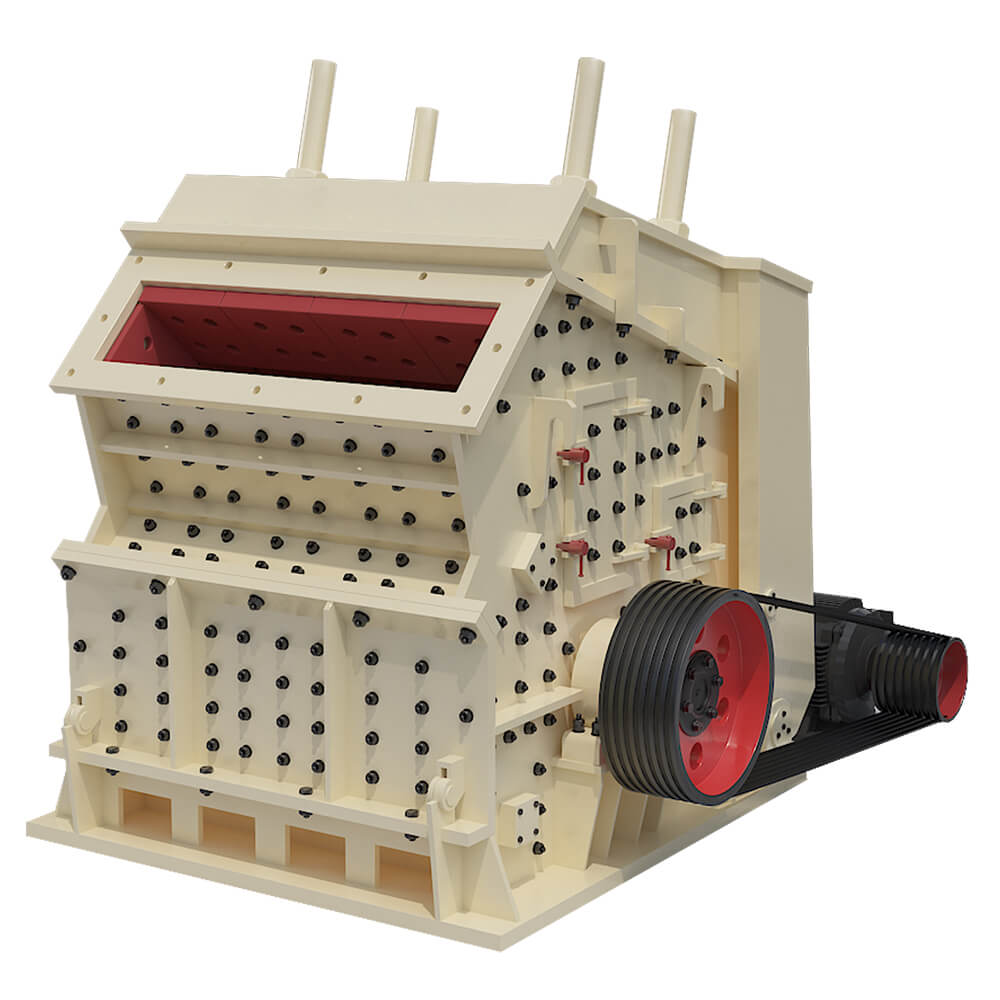

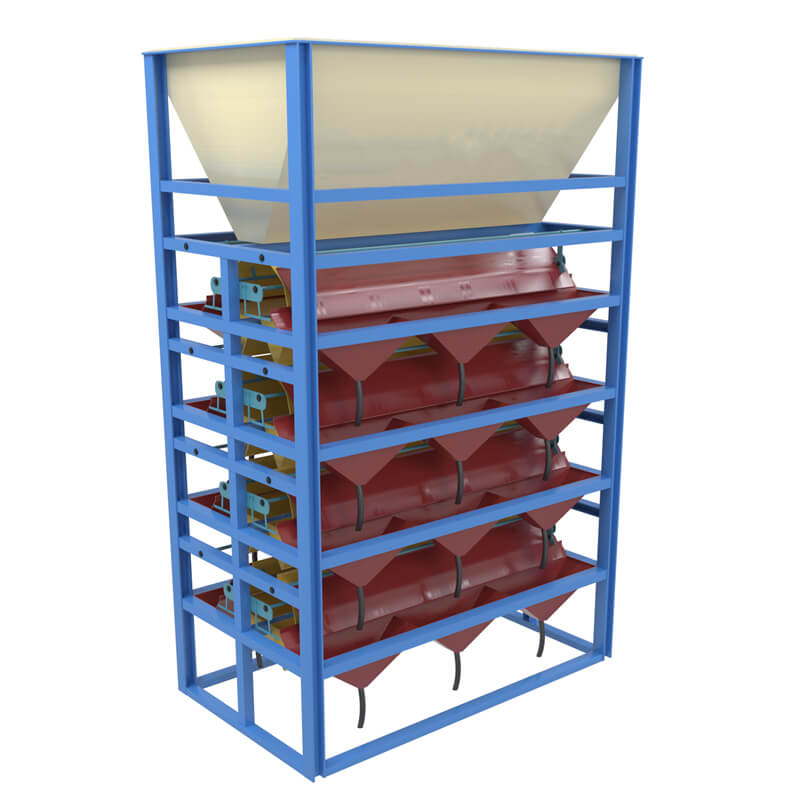

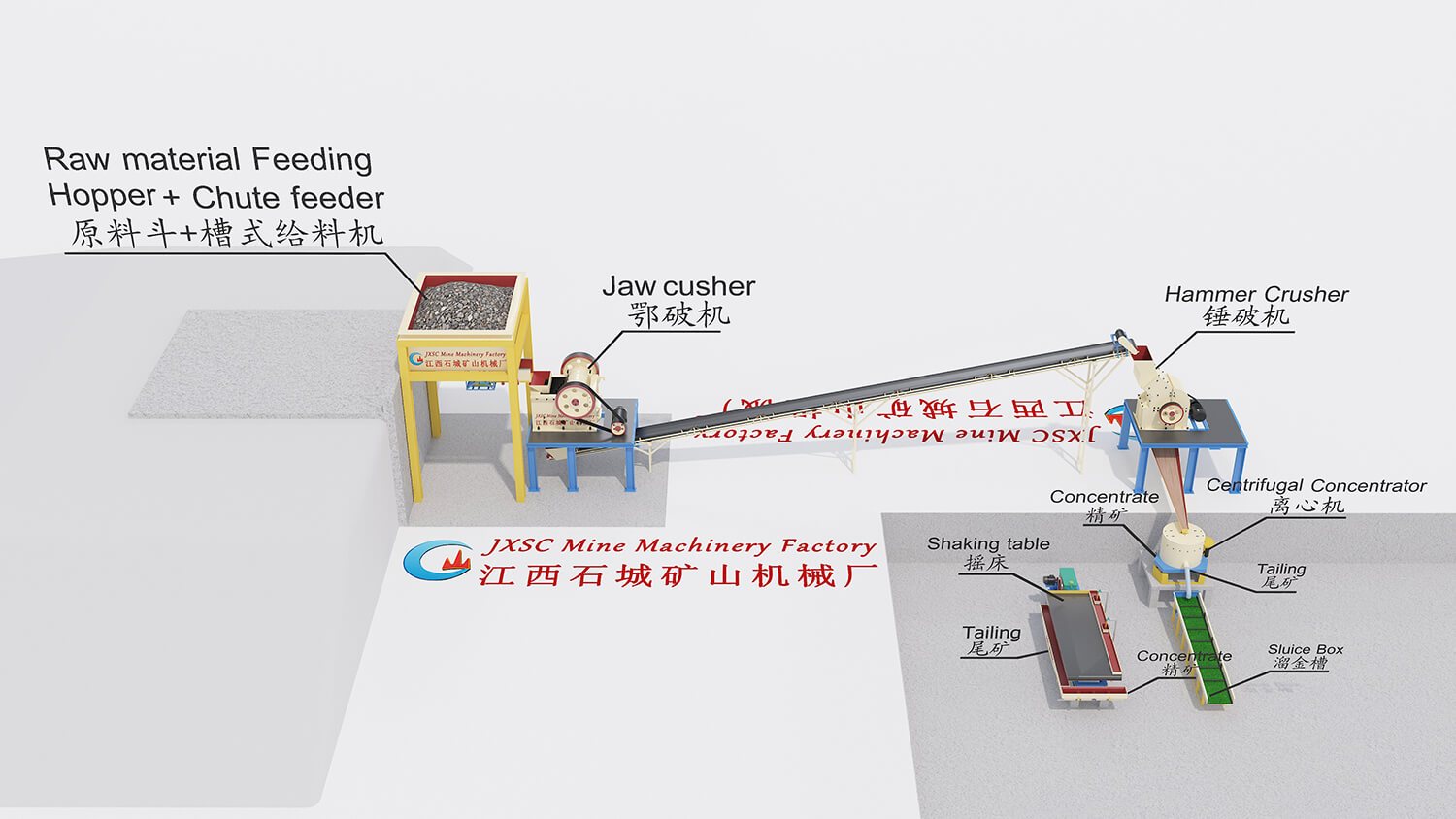

The crushing operation mainly includes two or three sections’ closed-circuit process. The coarse crushing adopts a jaw crusher or cone crusher, the crushing ratio is 3~4, and the particle size of the crushed product is 250~320mm. The medium and fine crushing operations use a cone crusher or jaw crusher, the crushing ratio is 4-6. The screening operation is set in the last crushing process, and it is designed as inspection screening or pre-inspection screening according to production needs, and the particle size of the final crushed product is controlled at 8-14mm.

The flotation of gold minerals generally adopts a one-stage grinding→ flotation process. The requirements for the grinding fineness of gold ore typically require only the dissociation of the sulfide ore monomer for gold wrapped in sulfide minerals. The grinding class of the gold continuously grown by the gangue needs to achieve the dissociation of the gold monomer.

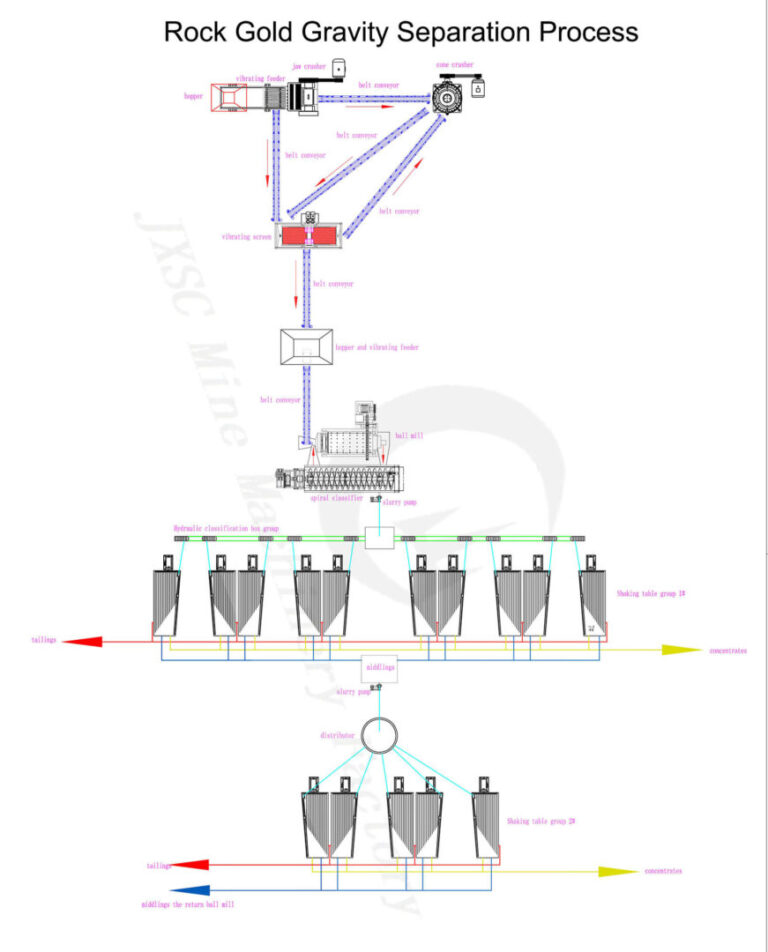

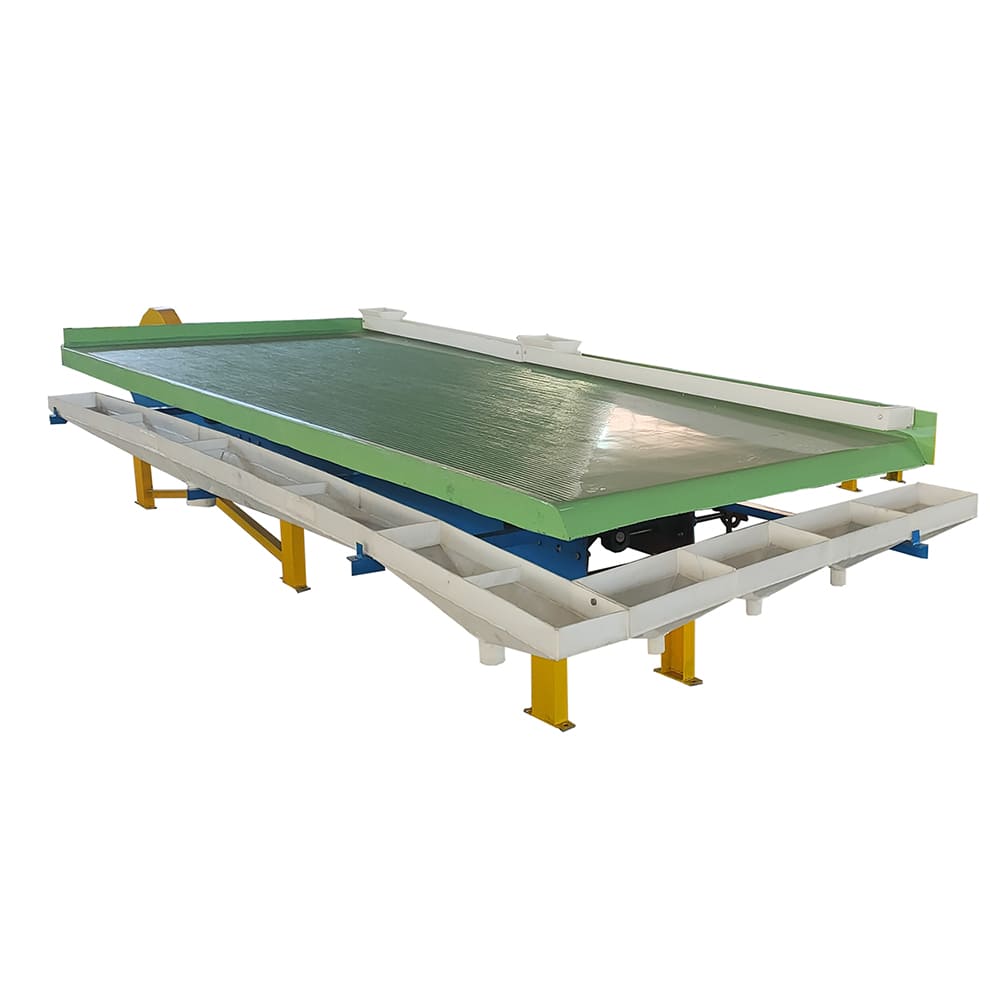

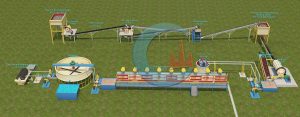

2. Rock Gold Gravity Separation Process

The primary beneficiation method of rock gold is flotation. Still, it can’t obtain a good beneficiation effect for coarse-grained crystalline rock gold ore, whether flotation or cyanide. In the beneficiation process, it must recover this kind of gold ore as soon as possible. Coarse-grained gold and fine-grained gold can be selected by flotation or cyanidation. For the beneficiation method of coarse-grained gold ore, due to the large specific gravity difference between gold and gangue, using gravity separation to grind and separate the basic monomers can obtain a good separation effect.

3. Rock Gold Mine Cyanidation Process

The gravity separation process is an essential prerequisite in the cyanidation process of rock gold ore. The gravity separation equipment can enrich the rock gold ore, and the amount of ore entering the cyanidation process is small. The cyanide consumption is low, the cyanidation efficiency of the gold ore is improved, the environmental pollution is small, and it can save the infrastructure investment and investment costs.

A vibrating screen and classifier separate the rock gold raw ore after being crushed by a jaw crusher and cone crusher. Return the unqualified ore materials to the ball mill for grinding. The qualified ore materials are cleaned, cleaned, and reground by the flotation machine. Finally, the leaching agitation tank is used to complete the cyanide gold separation process.