Gold Gravity Separation

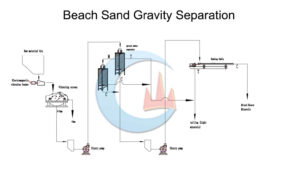

The gravity separations are simple and separate mineral particles of different specific gravity. As the density of gold mineral is much bigger than gangue mineral, for the gold mine which has gold particles people often use the gravity separation process. Gravity concentration is a proven process for mineral beneficiation.

Gold Gravity Separation Process

Introduction

About Gold Gravity Separation Solution

Gravity separation is one of the commonly used methods for gold ore dressing. It uses different specific gravity of materials and different settling speeds in the medium for layered separation. Generally, in placer gold, when gold mostly exists in the form of monomer natural gold, it has a large density difference with gangue, which is effective and economical for gravity separation.

Mineral Processing

Gold Gold Gravity Separation Process

There are many gravity separation methods, such as jig gravity separation, shaking table gravity separation, chute gravity separation, spiral gravity separation, centrifugal gravity separation, and wind gravity separation. In gold concentration, the commonly used gravity separation methods are gold jig separation, gold shaking table separation, and gold chute separation.

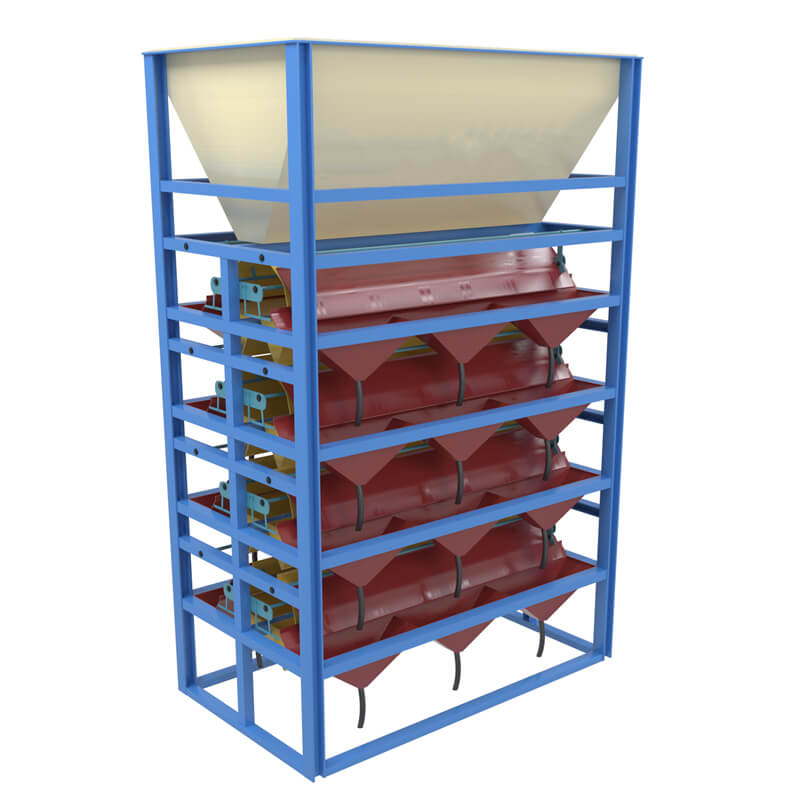

Jigging gold

The main equipment for jigging is the jig separator. The process of jigging is to mix mineral particles with different specific gravity and layer them according to specific gravity in the vertically moving variable-speed medium flow. The minerals with small specific gravity are located in the upper layer and the minerals with large specific gravity are located in the lower layer. Then, the layered materials are discharged respectively by using the functions of machinery and water flow.

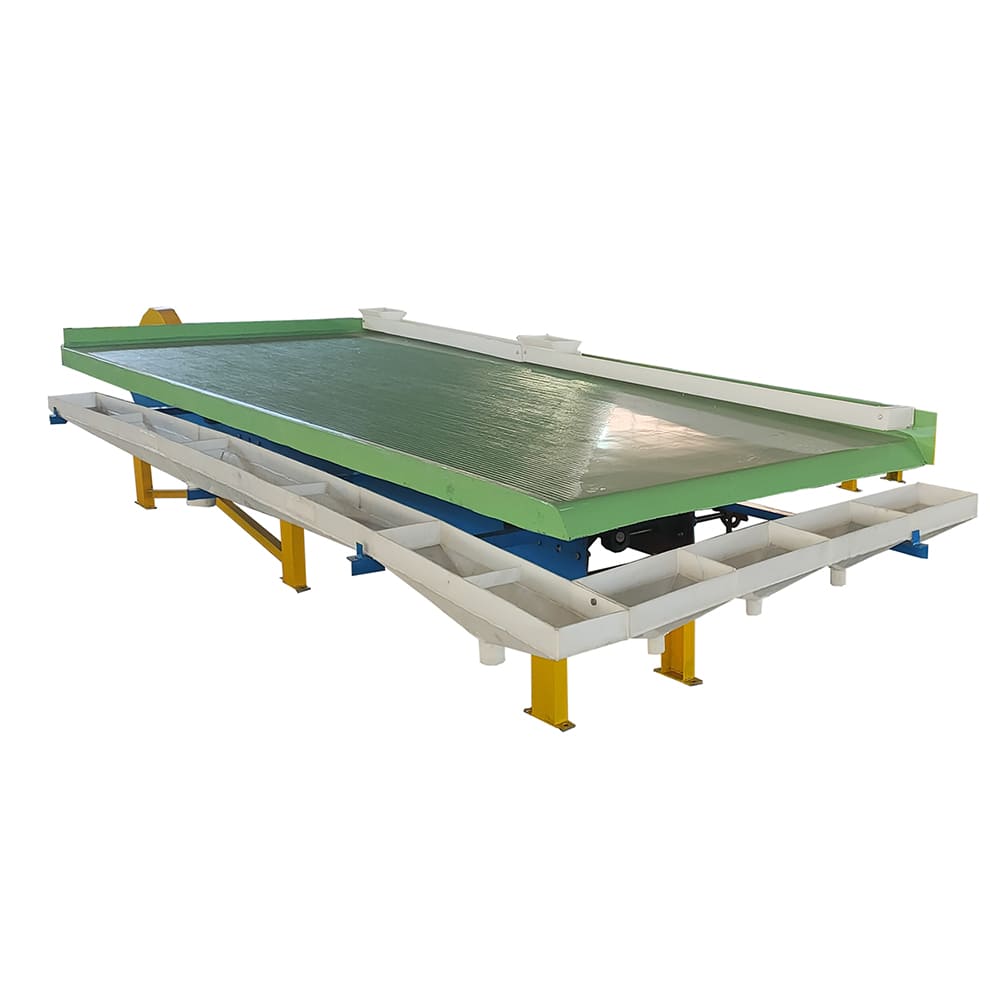

Shaking table gold selection

The main equipment of the shaking table gold separation is the shaker table, which is the equipment for separation in the horizontal medium flow. The transmission mechanism is used to drive the bed surface to make a longitudinal reciprocating motion, impulse flow, and differential motion of the bed surface. In the reciprocating motion, the ore particles undergo the stratification perpendicular to the bed surface and the separation parallel to the bed surface, so that the materials with different particle sizes can be discharged from different sections of the bed surface to realize separation.

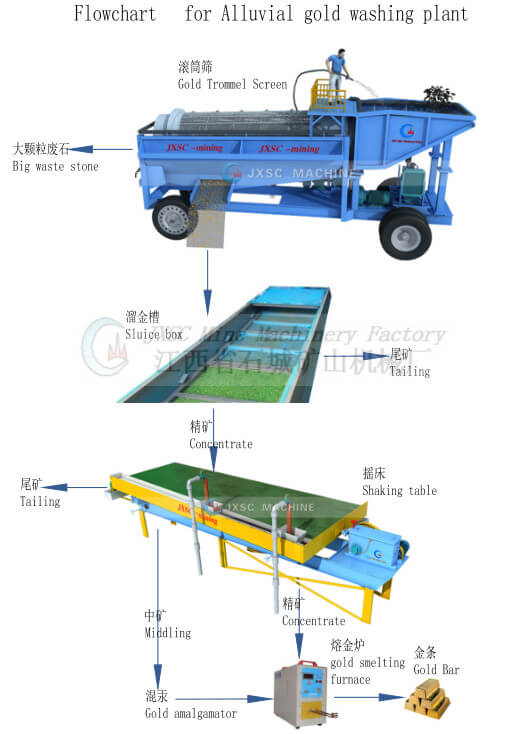

Chute gold separation

The main equipment for chute gold separation is a spiral chute, which uses inclined water flow for separation. Under the action of combined forces such as water flow, mineral gravity, and friction between ore particles and the bottom of the chute, the ore particles will settle in different areas in the chute according to specific gravity. The ore particles with small specific gravity will be taken away by water flow and leave larger ore particles, that is, the separation is completed. The chute is an intermittent operation. When the concentrate at the bottom of the chute is deposited to the moving degree, it is necessary to stop ore feeding and clear the concentrate before operation.

The above three gravity separation methods are only used for gold ore (placer gold) with monomer dissociation. For vein gold minerals, the gravity separation process is rarely used alone. Generally, it will form a combined process with other processes, such as the gravity flotation combined gold extraction process. Gravity separation is used to assist gold extraction. In the grinding and classification circuit, jig, spiral chute, and shaking table are used to recover the easily dissociated coarse-grained gold first, so as to create better separation conditions for subsequent flotation and cyanidation processes, finally, effectively improving the gold index and total gold recovery.

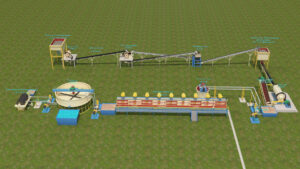

Gold Gravity Separation Plant 3D Videos

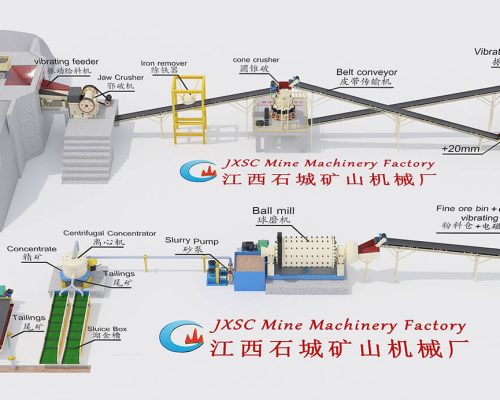

5TPH Rock Gold Gravity Processing Plant

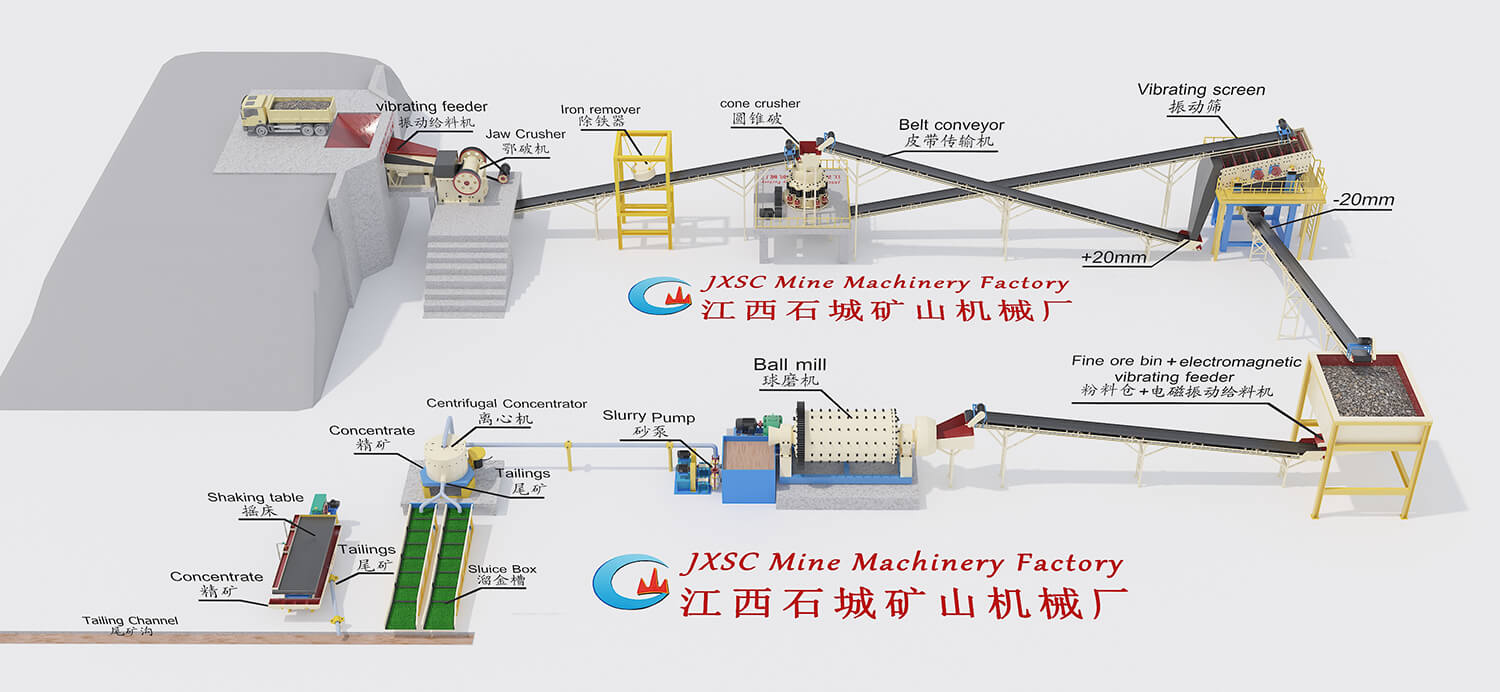

50TPH Rock Gold Gravity Separation Processing

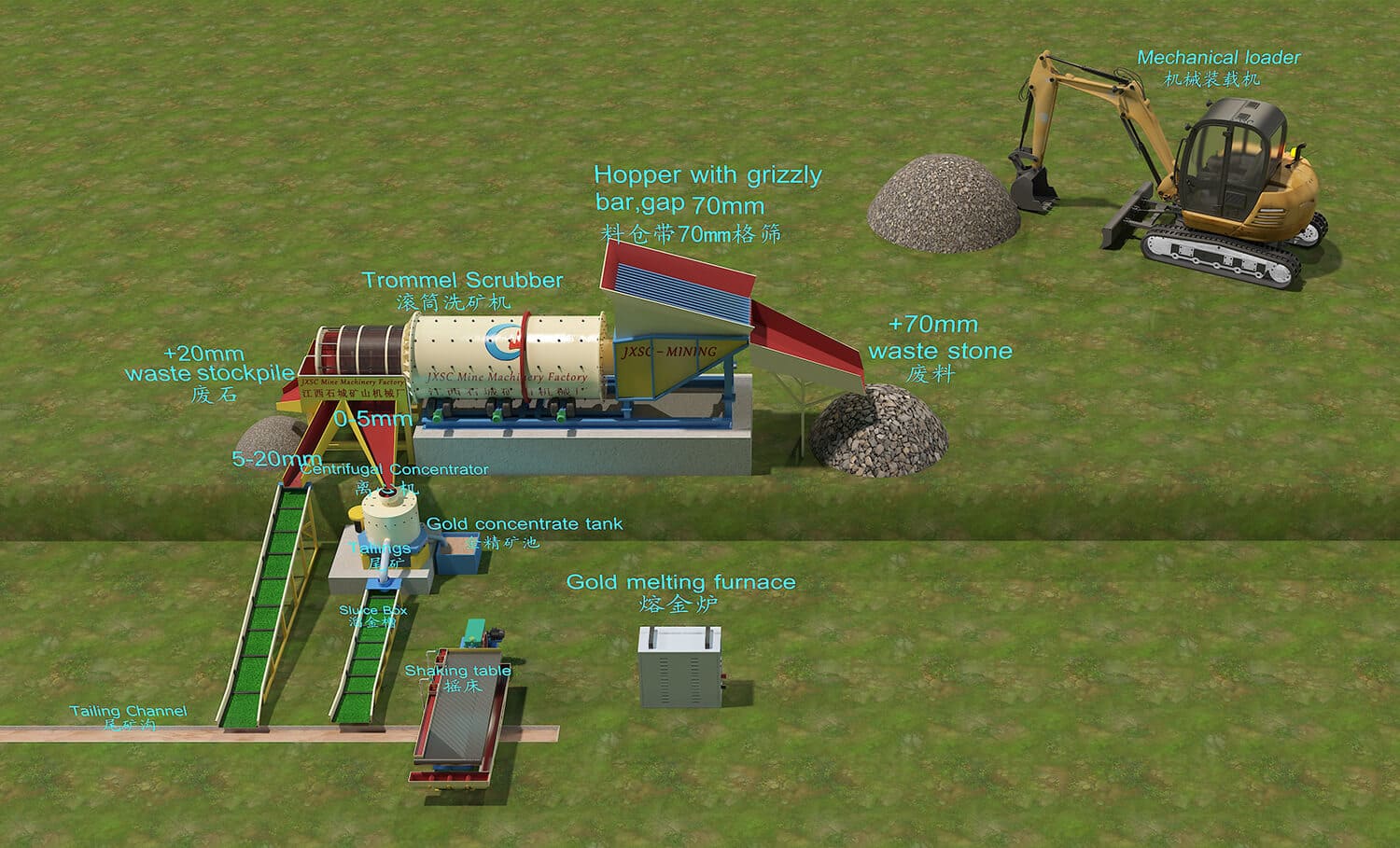

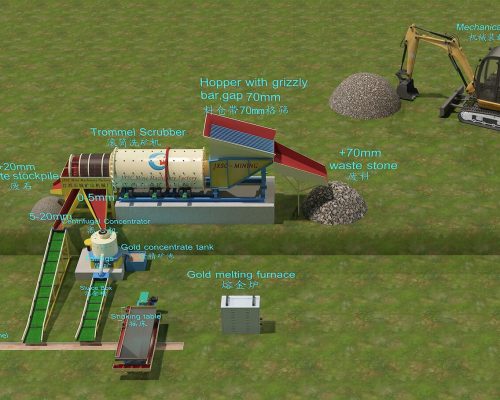

Alluvial Gold Washing & Gravity separation