Cobalt Mining Process

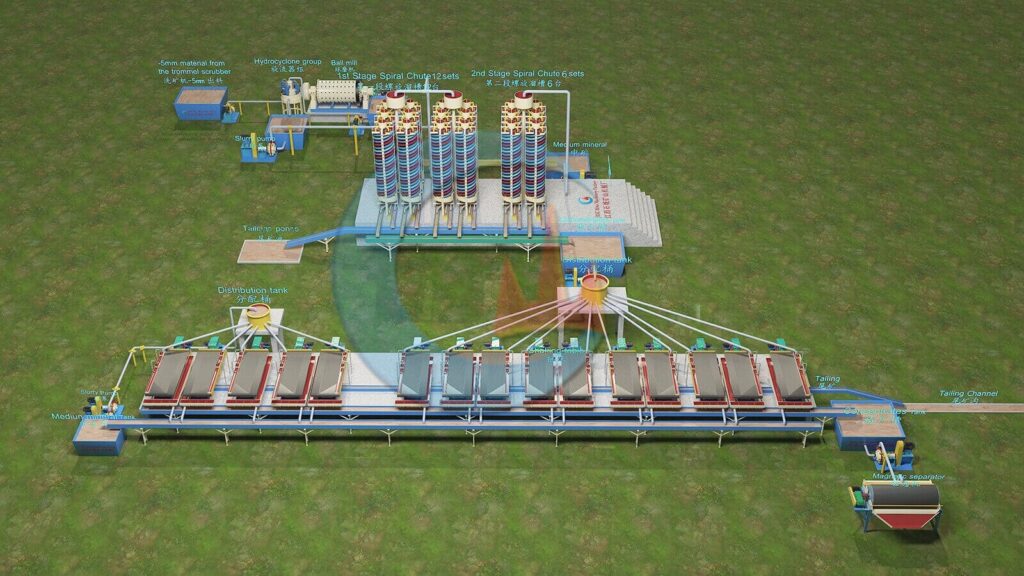

The vast majority of cobalt is associated with components in deposits of copper, nickel, iron, gold, etc., and only a small part forms independent industrial deposits. The separation of the metal cobalt, from raw ore to cobalt concentrate, will go through four stages, that is, “crushing-grinding-flotation-drying.” The main beneficiation methods are flotation, gravity separation, magnetic separation, mixed separation, and other processes.

Cobalt Ore Mining Process

Introduction

About Cobalt Ore

Cobalt is a magnetically hard metal with a high melting point and good stability. Its Curie point (the critical temperature point of losing magnetism) is 1150°C, it has permanent magnetism, its melting point is 1495°C, its boiling point is 2900°C, and it has high-temperature resistance. It is an important raw material for the manufacture of heat-resistant alloys, hard alloys, anti-corrosion alloys, magnetic alloys, and various cobalt salts. It is widely used in aviation, aerospace, electrical appliances, machinery manufacturing, chemical, and ceramic industries. Therefore, it is an important strategic material.

Mineral Processing

Cobalt Ore Processing

For the separation of the metal cobalt from raw ore to cobalt concentrate, there are four stages, “crushing – grinding – flotation – drying.”

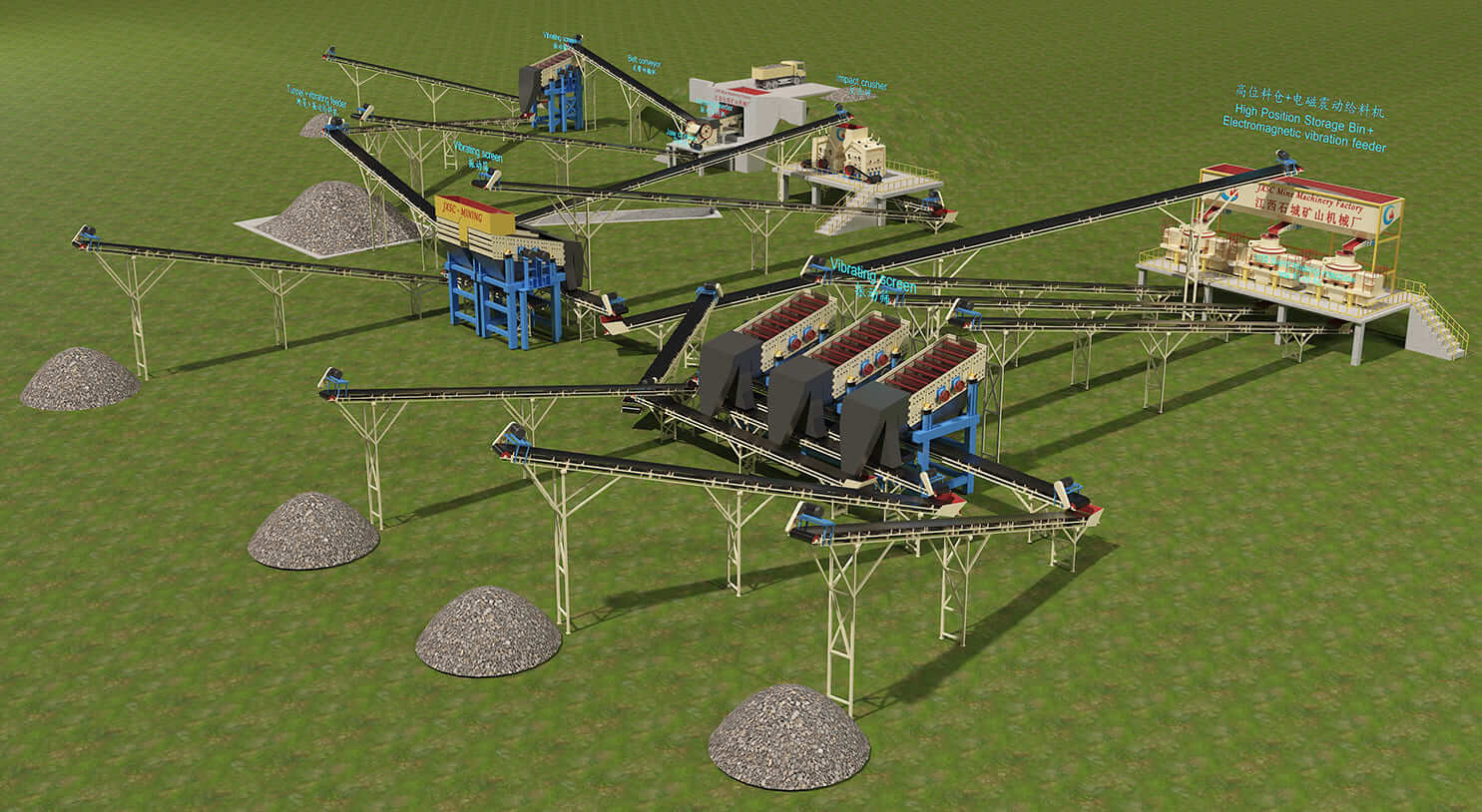

1. Cobalt ore crushing

In the crushing stage of cobalt ore, we need two stages of crushing to crush large pieces of raw ore into particles with a size of tens of millimeters for the next step of work.

2. Cobalt ore grinding

The finely crushed ore particles do not meet the flotation requirements, and the ore particles need to be further crushed before flotation. A ball mill grinds the coarse-grained ore and classifies it using a spiral classifier. The qualified ore particles enter the next flotation stage, and the unqualified ore particles are re-sent to the ball mill for grinding until they are qualified.

3. Cobalt ore flotation

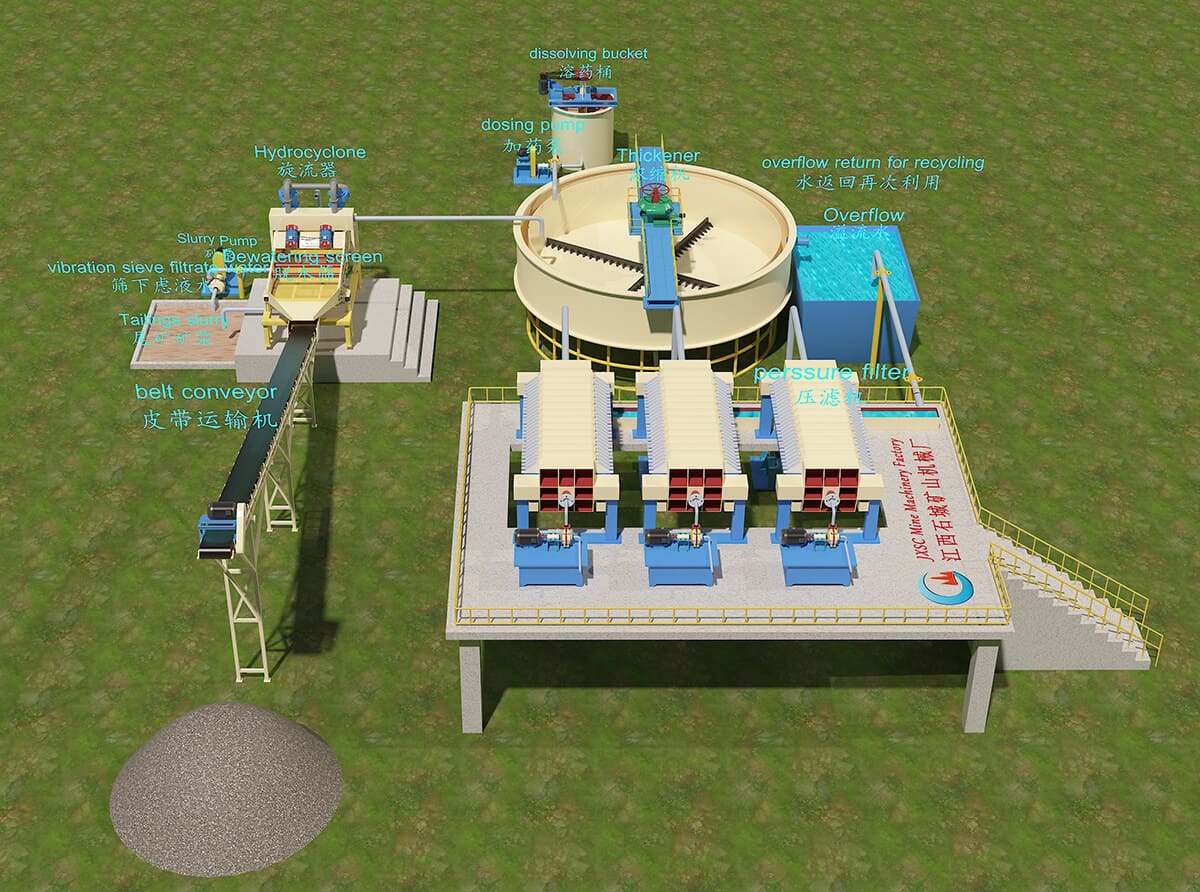

After grinding, the qualified cobalt ore powder is sent to the flotation machine for flotation, and a suitable collector agent is added to obtain high-grade cobalt concentrate.

4. Cobalt ore drying

The cobalt concentrate recovered by flotation contains a certain amount of water. It can not sale immediately or put into the next step of production before drying.

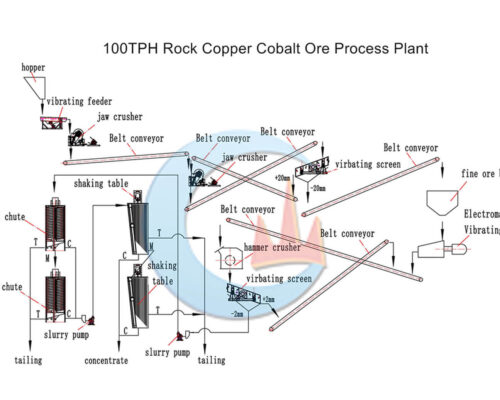

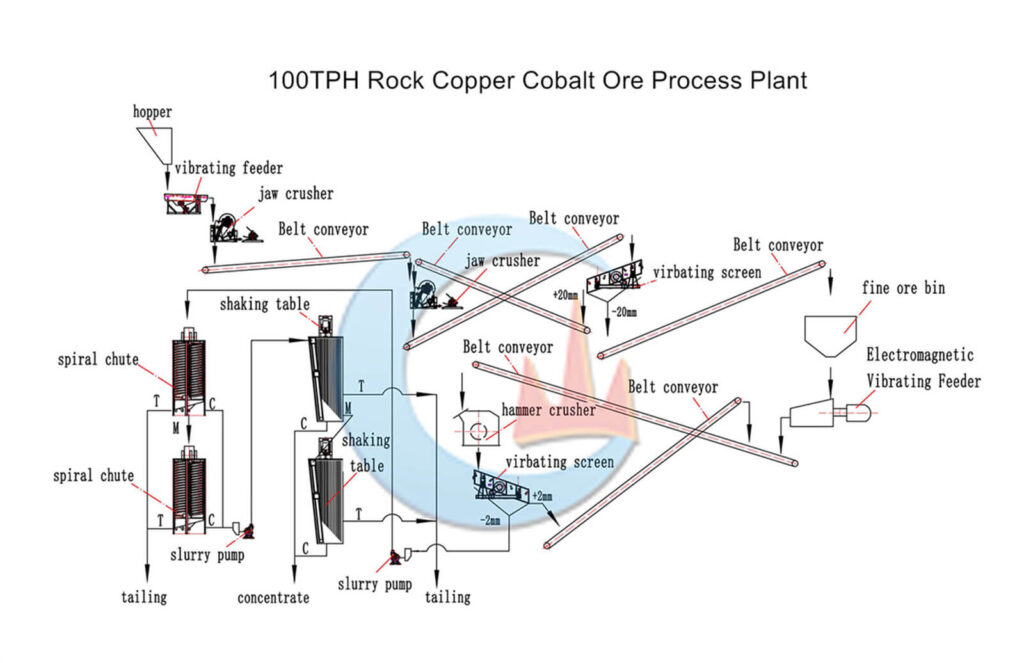

100TPH Rock Copper Cobalt Ore Process Plant

Cobalt Ore Beneficiation

In nature, most cobalt minerals coexist with metal minerals such as iron, copper, and nickel; a single cobalt mineral is rare. Common deposits of cobalt-bearing metals include copper-nickel-cobalt ore, copper-cobalt ore, iron-cobalt ore, and heavy iron ore.

1. The extraction process of copper-nickel-cobalt ore

The metal minerals in the copper-nickel-cobalt deposit mainly include copper, cobalt, nickel, etc., and the gangue minerals mainly include quartz, muscovite, biotite, plagioclase, serpentine, etc. There are many kinds of sulfide minerals. At the same time, copper, nickel, cobalt, and arsenic minerals have a close symbiotic relationship, and there are many independent minerals of arsenic.

A mixed flotation process generally treats copper-nickel-cobalt ore to obtain a copper-cobalt-nickel mixed concentrate with a large amount of enrichment. It can be sold or smelted at the same time. Be noted that this ore contains a large number of gangue minerals that are prone to pumice. And it is easy to produce secondary sludge during the grinding process, which affects the enrichment of copper-nickel-cobalt concentrate. Selective flocculation and desliming – mixed flotation process can be used. The copper-nickel-cobalt concentrate with a higher degree of enrichment is first mixed by flotation, and then the cobalt minerals are separated and extracted by hydrometallurgy.

2. Copper-cobalt ore beneficiation process

There are two kinds of copper-cobalt deposits, one often contains copper, lead, zinc, silver, and other polymetallic minerals, and the other contains copper, cobalt, uranium, and other minerals. The separation process of the two deposits is different, which is mostly determined according to the difference in floatability of copper and cobalt mineral materials, generally including the preferential flotation process and mixed flotation process. When using the priority flotation process to treat copper-cobalt ore, the first float is copper, then the cobalt. Lime, as an inhibitor, respectively obtains copper concentrate and cobalt-sulfur concentrate.

3. Iron-cobalt ore beneficiation process

Iron-cobalt deposits generally mainly contain cobalt minerals, such as pyrite, pyrrhotite, and a small amount of chalcopyrite. The main gangue minerals are quartzite, epidote, biotite, chlorite, and so on. Moreover, the components are relatively complex, and cobalt minerals are generally closely related to iron minerals. This ore can be processed by flotation—first, separate sulfide and magnetite. Then separate a small amount of chalcopyrite, pyrite, and pyrrhotite by flotation and separation of magnetite by magnetic separation to obtain copper, cobalt-sulfur, and iron concentrate.

4. Manganese-cobalt ore extraction process

It mainly occurs in weathered sediments. In addition to cobalt, it also contains metal elements such as manganese, copper, nickel, and iron. Complexes of manganese oxide and cobalt oxide usually dominate the mineable portion of the ore. Cobalt minerals have a close symbiotic relationship with manganese minerals and contain more clay, iron mud, and limonite. Manganese minerals are usually recovered together with cobalt minerals. Manganese-cobalt ore can choose a single or combined extraction process. Single extraction methods include gravity separation, magnetic separation, flotation, acid leaching, etc. The combined extraction methods include the roasting-flotation method and the acid leaching-flotation method. The acid leaching-flotation method is the most commonly used manganese-cobalt ore beneficiation method.