Coal Washing Process

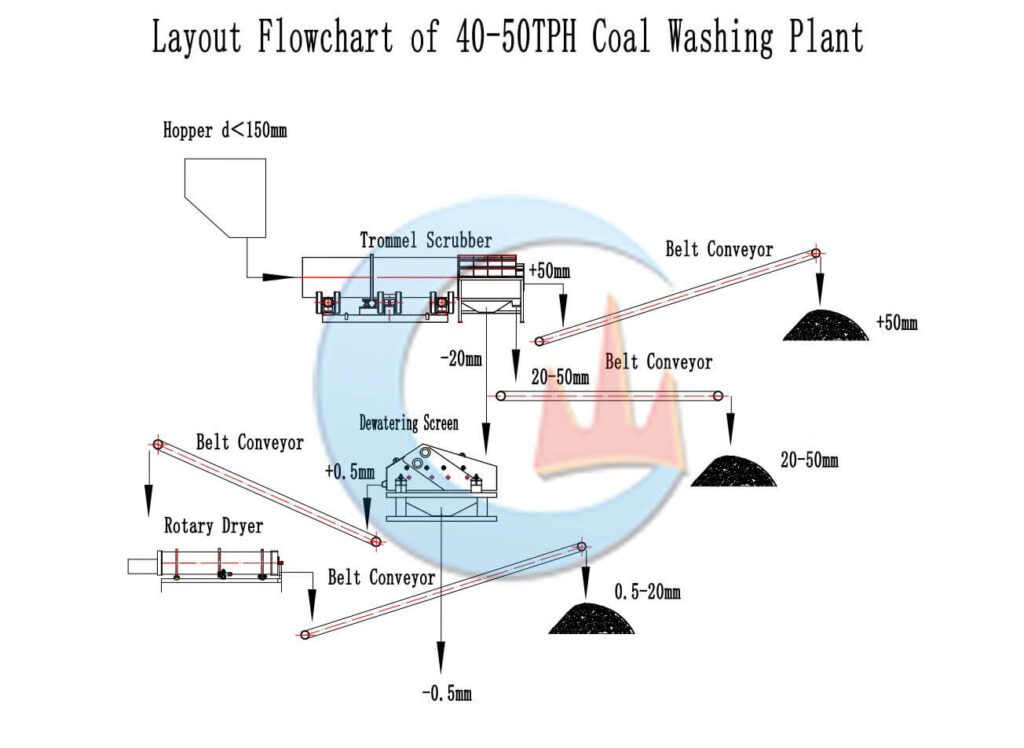

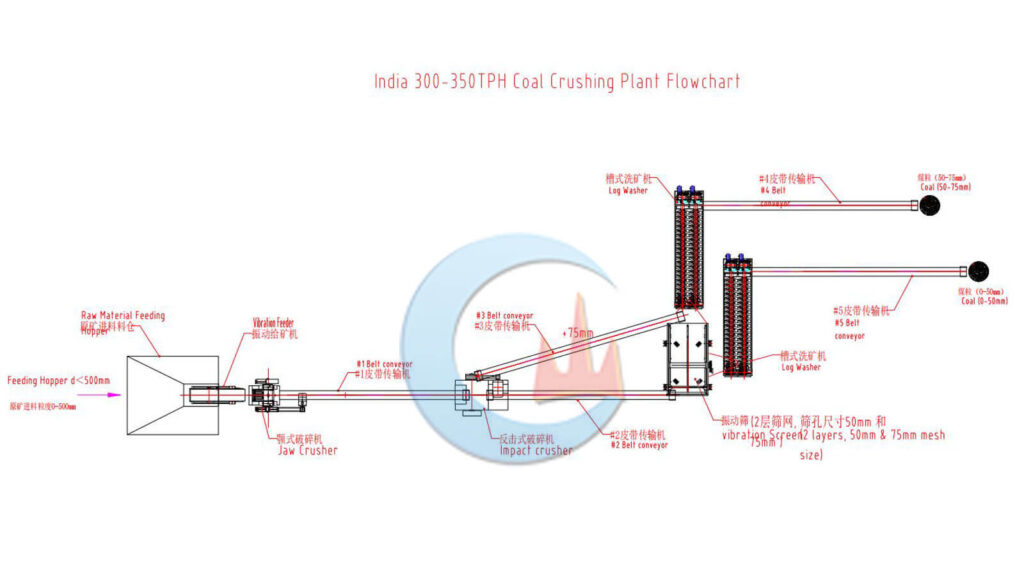

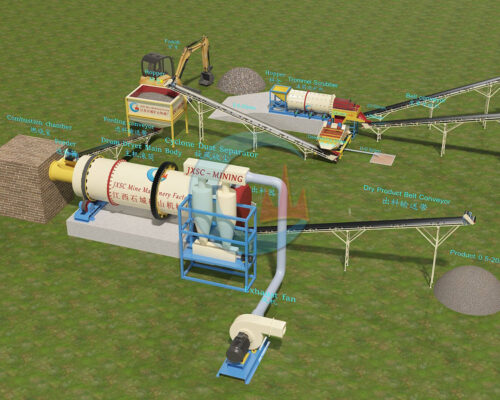

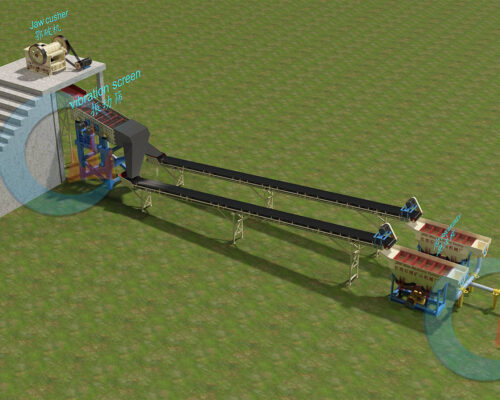

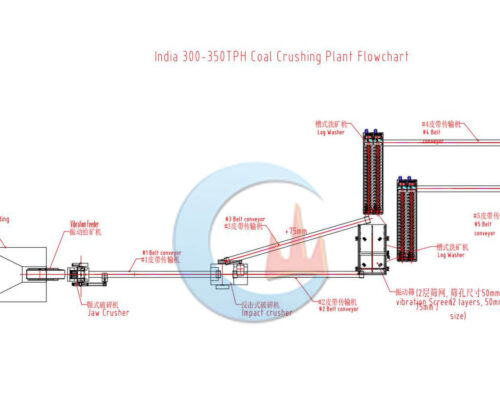

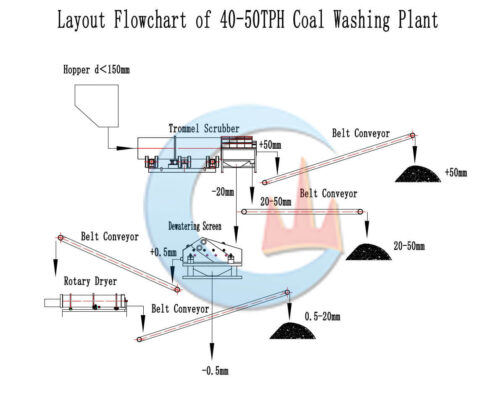

The coal beneficiation or coal preparation process separates inorganic impurities from raw mined coal, reducing the concentration of unwanted material or gangue and thereby providing improved combustion characteristics to the fuel produced. The commonly used beneficiation methods for coal sorting and processing include jig separation, heavy medium, and flotation.

Coal Beneficiation

Introduction

About Coal Mines

Coal is the most important solid fuel and combustible organic rock. It is formed by luxuriant plants growing in a certain geological age, gradually accumulating into a thick layer in a suitable geological environment, buried in the bottom of the water or the sediment, and formed by natural coalification in a long geological age.

Generally, we divide coal mines into underground and open pit coal mines.

Underground Coal Mine: The coal seam is far from the surface, excavating the mine coal underground tunnels.

Open-pit coal mine: The coal seam is very close to the surface, directly stripping the surface soil layer to excavate the coal.

Coal Types

- Anthracite: It contains the highest amount of carbon out of all coal ranks (86%-97%). It is a hard, brittle, and black lustrous coal, often referred to as hard coal, containing a high percentage of fixed carbon and a low percentage of volatile matter.

- Bituminous: It is often called “soft coal,” and has slightly lower carbon content than anthracite (45%-86%). It can be identified through its shiny luster and layered texture.

- Subbituminous: It has lower carbon content than bituminous coal (35%-45%) and is primarily used for electricity generation. It is black in color and is mainly dull (not shiny).

- Lignite: It is often called brown coal, and has the lowest carbon content out of all the coal ranks (25%-35%). Lignite has a low heating value and a high moisture content and is mainly used in electricity generation.

- Peat: It is a soft, organic material consisting of partly decayed plant and mineral matter. Peat is the first step in the formation of coal and slowly becomes lignite after pressure and temperature increase as sediment is piled on top of the partially decaying organic matter.

Mineral Processing

Coal Ore Processing

Coal Treatment

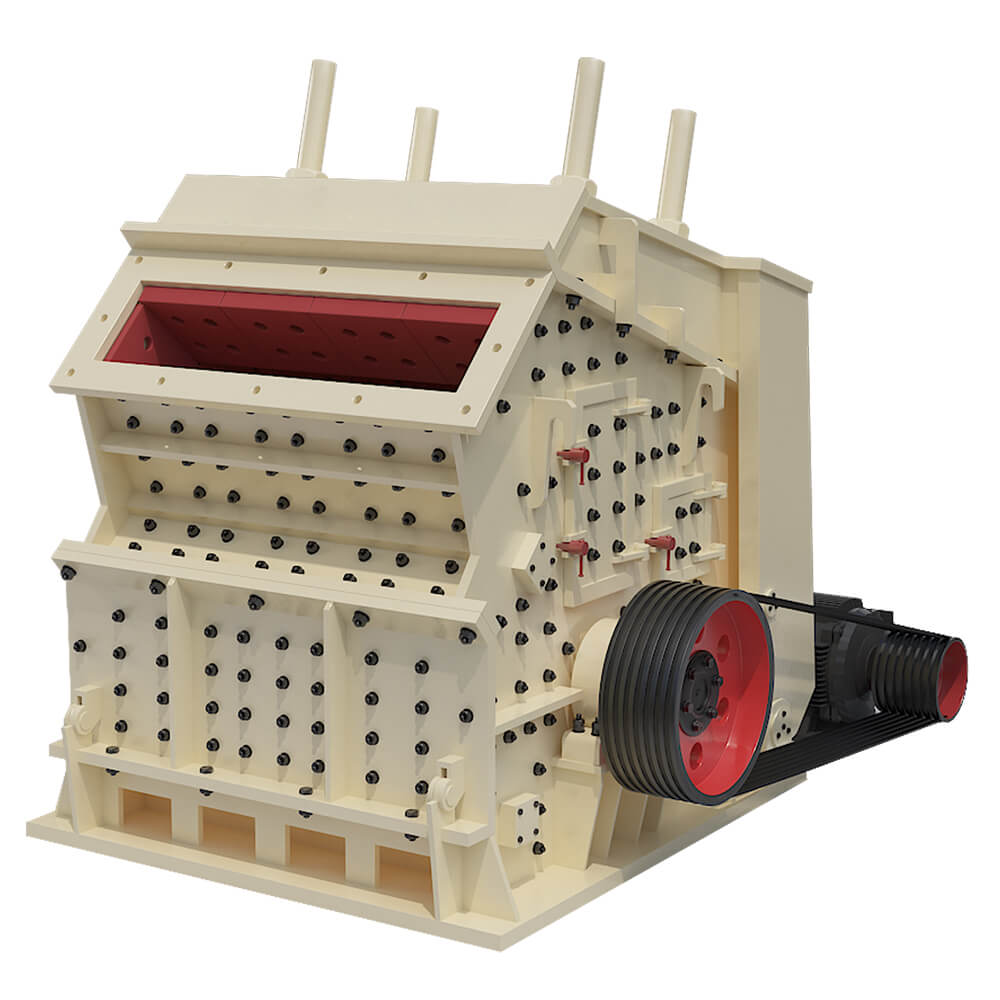

Different types of coal have different processing techniques. Generally, coal preparation methods are divided into several types: hand-selected, gravity coal preparation, flotation & special coal preparation method.

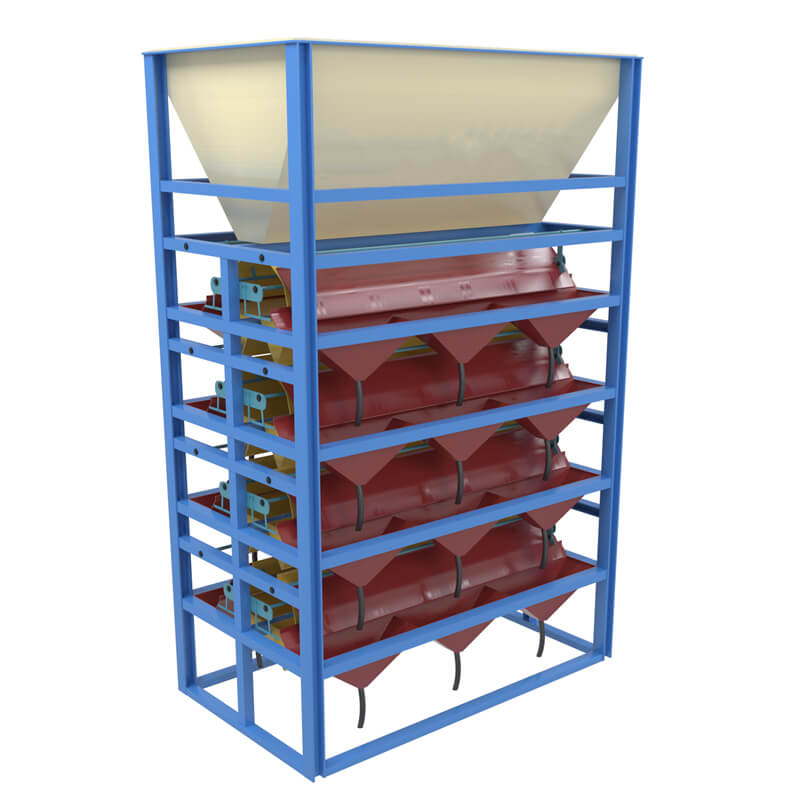

Among the various coal preparation methods mentioned above, wet gravity coal preparation is widely used. Jigging, heavy medium (mainly resuspension) coal preparation, and flotation are the main coal preparation methods at present. The practice has proved that jig separation can be used for easy coal separation. Heavy medium separation is used for difficult or extremely difficult coal separation. Flotation is an effective method for selecting coal slime.

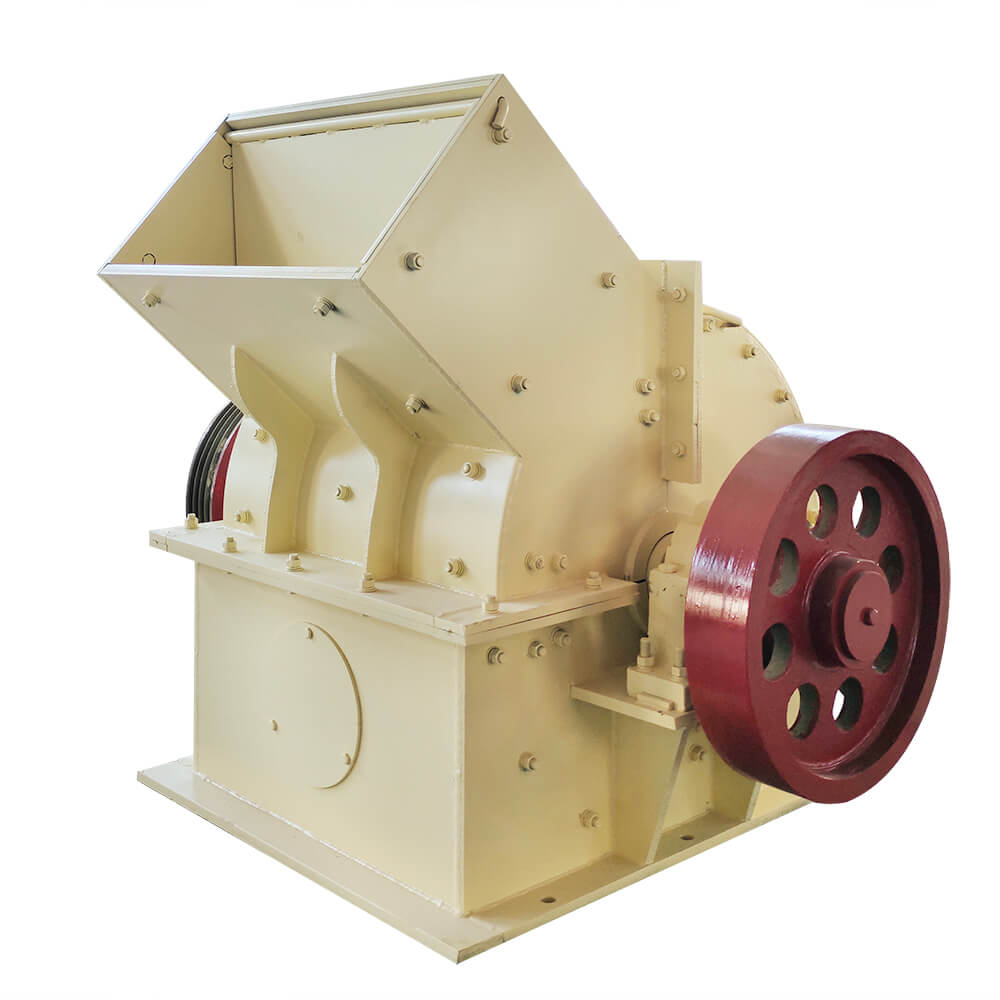

Gravity Coal Separation

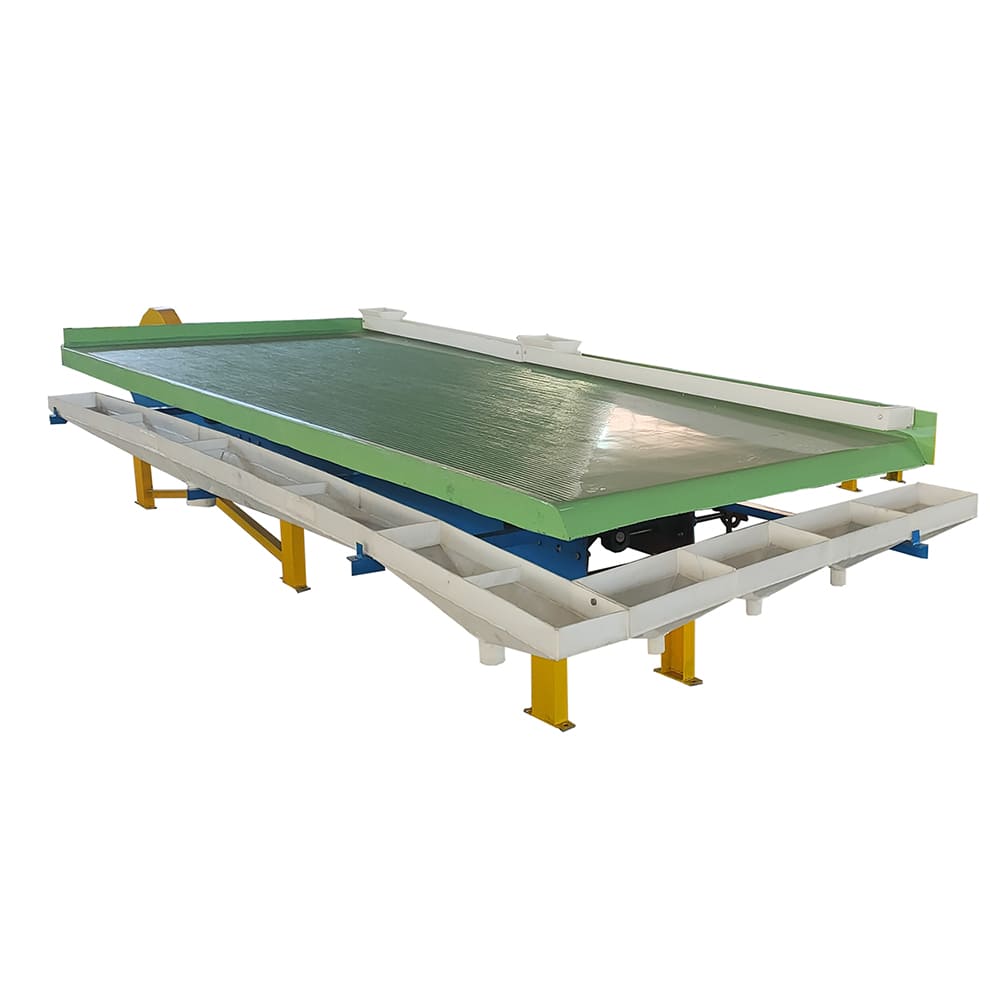

The method of separating coal and impurities (gangue) according to the density difference is called gravity coal separation. Gravity coal preparation methods include jig coal preparation, dense medium coal preparation, shaking table coal preparation, launder coal preparation, inclined groove coal preparation, and cyclone coal preparation.

Flotation Coal Preparation

Flotation, which is a coal preparation method for sorting fine-grained coal (<0.5mm) based on the difference in the wettability of the surface of coal and gangue.

Peat Coal Flotation: With the continuous improvement of the degree of mechanization of coal mining and the increasing depth of coal mining, the amount of pulverized coal <0.5mm in the raw coal is also increasing, generally reaching more than 20%, so the recovery of this part of the clean coal is more efficient. important. The flotation machine has developed rapidly, the flotation column technology has been popularized and applied, and the microbubble flotation machine and the jet flotation machine have also been applied in many coal preparations.

Special Coal Preparation

It mainly uses the difference in electrical conductivity, magnetic permeability, friction coefficient, and ray penetration ability between coal and gangue to separate coal and gangue. It includes electrostatic separation, magnetic separation, friction separation, radioisotopic separation and x-ray separation.