Andesite Sand Making

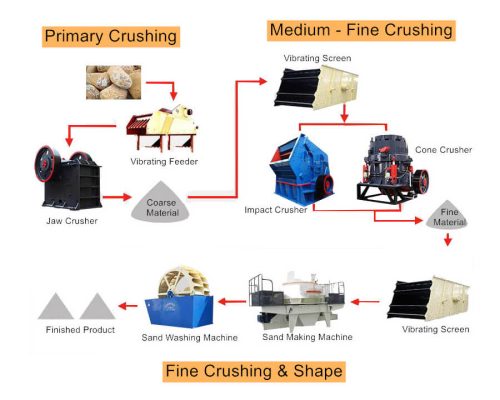

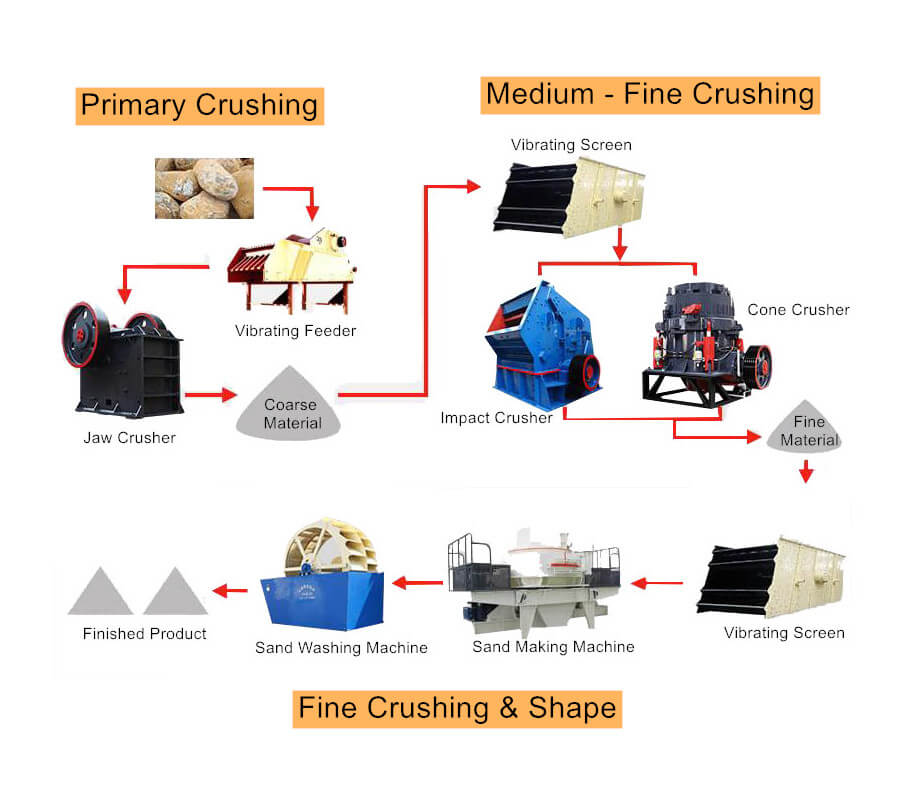

Andesite is a neutral calc-alkaline extrusive rock. Its composition is equivalent to diorite. The andesite crushing and sand-making production line has reliable performance, reasonable design, convenient operation, and high work efficiency. The process flow of its crushing production line is silo –> feeder –> jaw crusher –> cone crusher –> vibrating screen –> impact crusher –> vibrating screen –> Finished products.

Andesite Crushing & Sand Making

Introduction

About Andesite Ore

Andesite is a volcanic rock consisting of the plagioclase feldspar minerals andesine and oligoclase, together with one or more dark, ferromagnesian minerals such as pyroxene and biotite. Its grains are fine, with a grain size between basalt and rhyolite. Andesite is a neutral rock with a chemical composition between acidic and basic rocks.

The andesite formation is often associated with volcanic activity and can be found near volcanic eruptions and vents. The composition and structure of this rock can provide information about Earth’s internal processes because it formed during magmatic processes deep in the Earth’s crust.

Andesite has certain uses in construction and stone and is often used in road paving. Due to its relatively strong nature, it has found some applications in the construction and engineering fields.

Major minerals of Andesite: Plagioclase, hornblende, almandine.

Accessory minerals of Andesite: Ilmenite, apatite, and orthopyroxene.

Application and Uses: Construction materials, pavement and road construction, monuments and sculptures, countertops and tiles, cemetery markers, gravestones and grave markers, water features, decorative landscaping, fireplace surrounds, aquariums and terrariums, scientific research, jewelry, etc.,

Mineral Processing

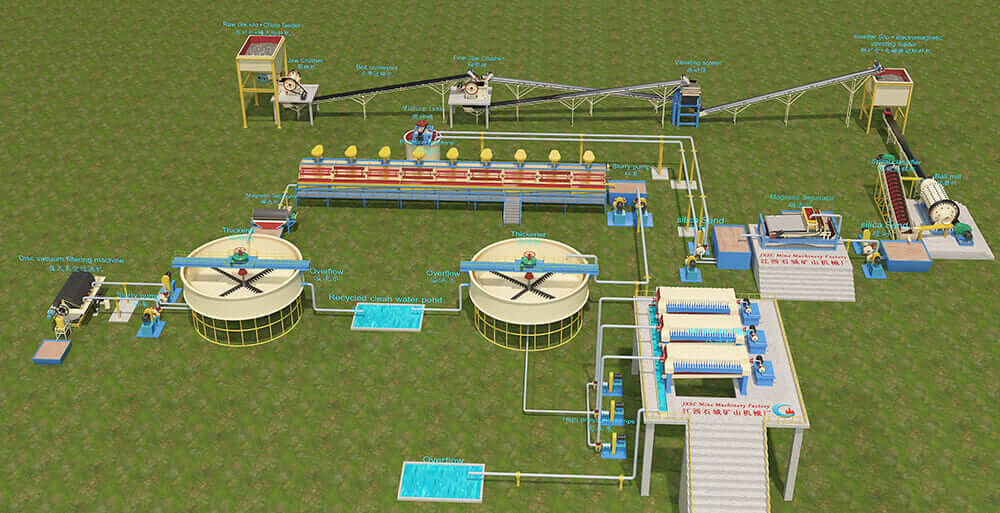

Andesite Sand Making Process

Coarsely Crushing

The mined andesite is evenly sent to the jaw crusher by the vibrating feeder and then crushed to the required particle size in the jaw crusher before entering the next step;

Medium Crushing

The materials crushed by the coarse jaw crusher are sent to the cone crusher at a constant speed by the belt conveyor for secondary crushing. After being crushed to the required particle size, they are sent to the circular vibrating screen for screening. If the particle size is qualified, it will be sent to the fine crushing link; if the particle size is not qualified, it will be returned to the cone crusher for further crushing;

Sand Making

The belt conveyor sends the qualified andesite to the sand-making machine for fine crushing and shaping. The circular vibrating screen screens the fine andesite particles. The particle size is suitable for the next step of cleaning and is not ideal for returning to the andesite sand-making machine for further crushing;

Washing

The qualified andesite particles are sent to the sand washer for cleaning. After cleaning, the dehydrated and dried materials can be used as building materials.

Andesite Crushing Process

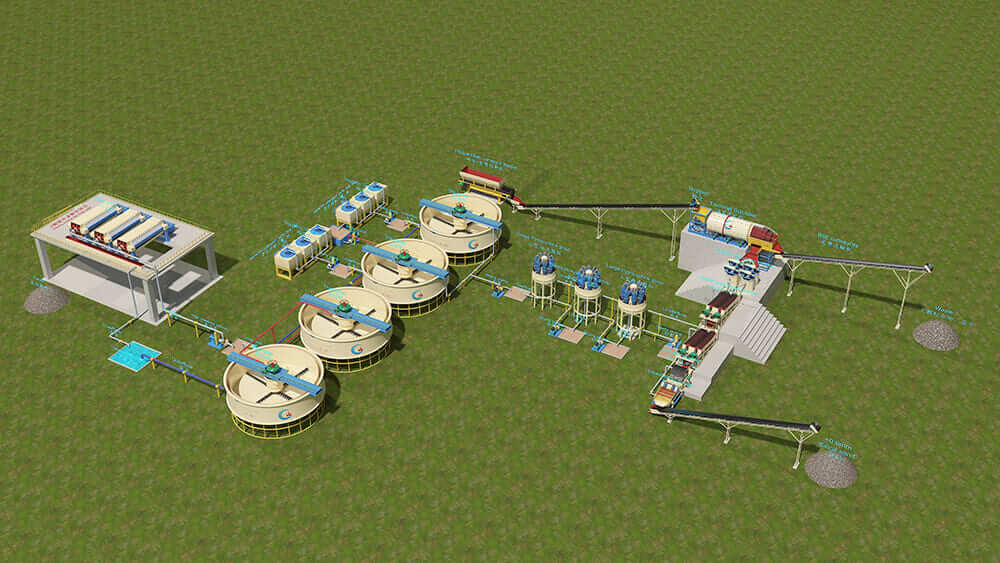

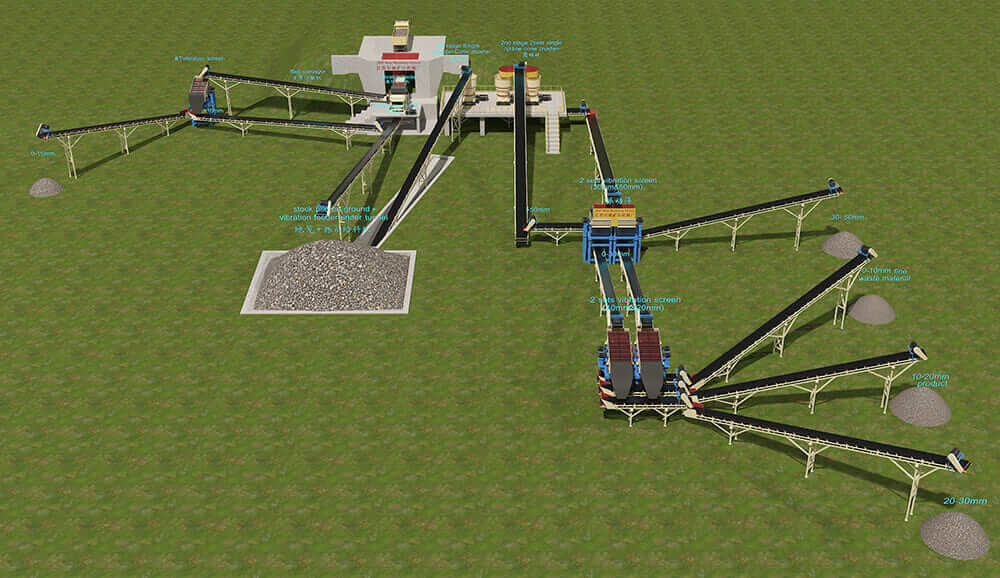

750TPH andesite crushing plant

The 750TPH andesite crushing plant is configured with a vibrating grizzly feeder. The scalping vibrating screen is for screening the materials underneath the grizzly. The output from the jaw crusher and overscreen materials will enter a tunnel bin via a belt conveyor for temporary storage. The bin feeder will feed stones from the tunnel bin to the secondary cone crusher; the crushed materials will go to vibrating screens number 1 and 2 for screening. The over 50mm materials will return to tertiary cone crushers for re-crushing, 30-50mm materials go to stockpile by a belt conveyor, 0-30mm materials will be processed by vibrating screen number3 and number4 to get 0-10mm,10-20mm, 20-30mm final products.

The screen mesh can be replaced easily to get your ideal final product sizes. The capacity for this crushing plant can be customized as per request, such as 50tph,100tph, 200tph, etc.