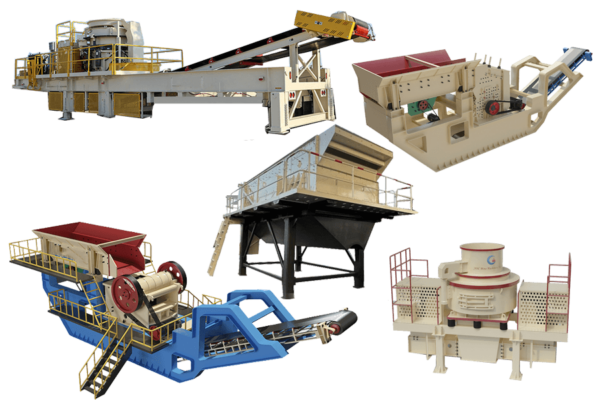

Modular Crushing & Screening System

Feeding Size: 0-1200mm

Capacity: 0-1200 TPH

Application: Barite, manganese ore, granite, limestone, dolomite, river pebbles, iron ore, copper ore, basalt, gold ore, etc.,

Standard Modular Crushing And Screening Plants: Jaw, cone, impact crusher station, sand-making machine station, screening machine station.

Modular crushing plants can meet your needs. Pre-engineered standard components make installation simpler, faster, and easier.

Standard Modular Crushing And Screening Plant

The modular crushing and screening system provides flexible and quick-starting crushing and screening solutions to meet the needs of different customers, especially for open-pit mine crushing. Standardized and modularized products are fast and straightforward to install, reduce infrastructure and installation costs, facilitate rapid operation, and quickly realize investment returns, excellent screening capacity, intelligent process control, easy operation, complete accessories, and screen support.

- The jaw crusher module station: Uses for primary crushing of minerals and rocks.

- The cone crusher module station: Uses for medium and fine crushing of minerals and rocks with medium hardness and above.

- The impact crusher module station: Uses for medium crushing of minerals and rocks below medium hardness.

- The sand-making machine module station: Uses in the construction and non-mining industries to process and produce high-quality sand or granular materials.

- The screening machine module station: Uses to support the coarse crushing module of the jaw crusher and the cone crusher’s medium and fine crushing module, to screen and classify the crushed products.

Application

- Reuse of construction waste

- Stone quarry crushing sand

- Municipal Construction Engineering

- Mining crushing

- Metal mineral crushing

- Coal mine crushing

Features

- The structure design is compact, saving space and reducing the construction site’s floor area.

- The foundation is easy to deal with, and the equipment foundation is small, which avoids the difficulty of civil construction.

- All modules are factory-tested and assembled in advance, shortening the on-site installation time.

- The equipment and process are coordinated and smooth, with a high degree of matching in model selection and high operating efficiency.

- The equipment installation and maintenance are convenient, fast, safe, and efficient.

- The modular station is easy to dismantle and reinstall, ensuring that the project can be quickly relocated and reassembled according to construction needs.

What We Do?

- Rock Crushing Solutions

- Mineral Dressing Solutions

- Aggregate Solutions

- Construction Waste Recycling

- Artificial Sand-making Solutions

Why Choose Us?

- Around 40 Years' Rich Experience

- Multiple Mineral Project Cases

- Quality Construction & Reliability

- Global Cooperation Customers

- Excellent Service System

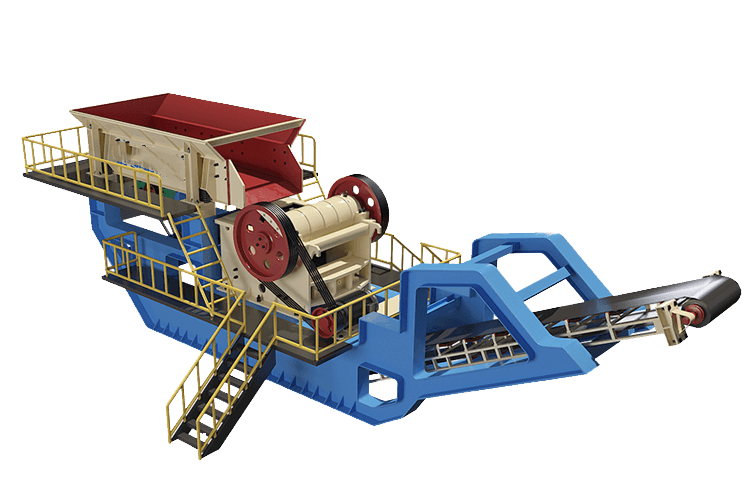

Jaw Crusher Plant

Primary Crushing of Minerals and Rocks

Capacity: 1-1120t/h

Feed Size: 100-1200mm

Output Size: 10-350mm

Configure Equipment: Feeders, jaw crushers, belt conveyors, and modular structural parts.

Main Module Structure: Feeding bin, equipment support, maintenance platform, ladder railing, feeding, and discharging chute.

Cone Crusher Plant

Medium & Fine Crushing of Minerals & Rocks Above Medium Hardness

Capacity: 30-1200 t/h

Feed Size: 5-350mm

Output Size: 5-60mm

Configure Equipment: Cone crusher, modular equipment base structural parts.

Main Module Structure: Equipment support, maintenance platform, ladder railing, in and out hopper, intermediate silo.

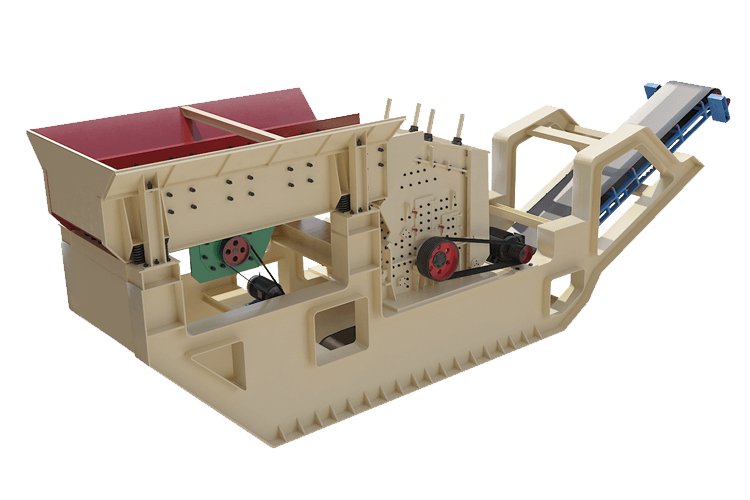

Impact Crusher Plant

Secondary Crushing of Minerals & Rocks Below Medium Hardness

Capacity: 10-350 t/h

Feed Size: 100-500mm

Output Size: 10-80mm

Configure Equipment: Impact crusher, in and out of the hopper,modular structural parts

Main Module Structure: Equipment support, maintenance platform, ladder railing, access hopper.

Screening Machine Module Station

Capacity: 10-800 TPH

Screen Mesh: 3-80mm

Screen Layer: 1-4 layers

Configure Equipment: Vibrating screen machine, modular structural parts

Main Module Structure: Screening machine, slide-out chute, fine material discharge chute, platform module, the support module, ladder handrail module.

The screening machine module station is mainly used to support the coarse crushing module of the jaw crusher and the cone crusher’s medium and fine crushing module to screen and classify the crushed products.

Features

- Beautiful and simple structure, all independent workpieces can be disassembled, and they are easy to assemble, disassemble, and transport.

- The slide-out discharge chute at the front provides convenience for the maintenance of the screening machine.

- The collapsible lower discharge chute makes it easy to transport and install.

- Ladders, handrails, and surrounding walkways are convenient for inspecting and maintaining any part of the vibrating screen.

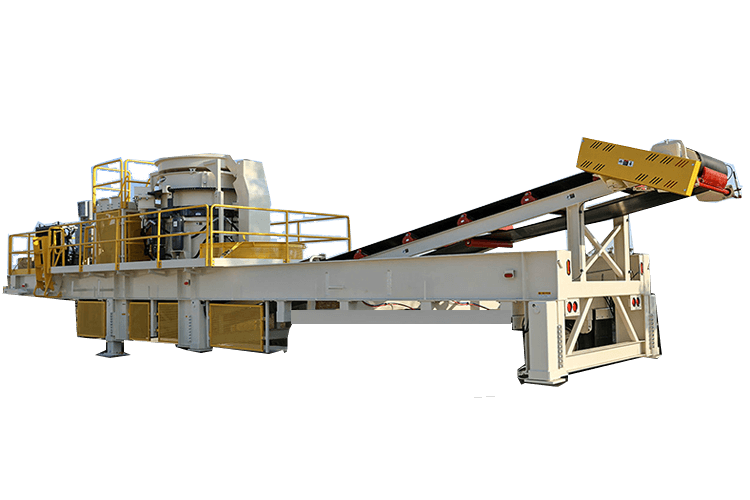

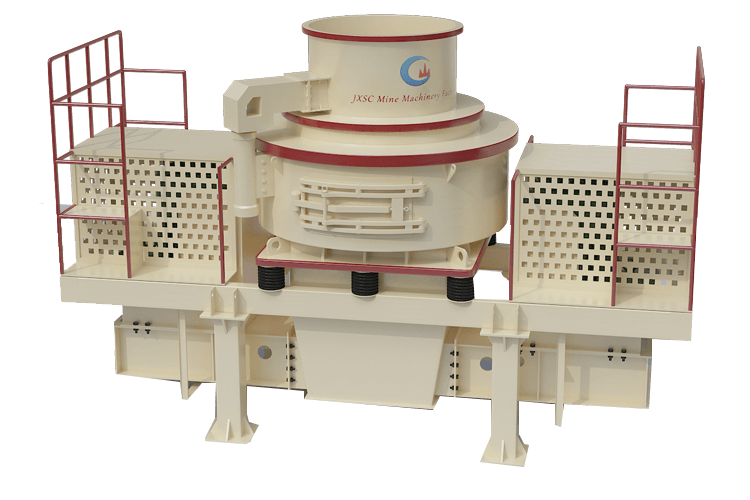

Sand Making Plant

Capacity: 120-640t/h

Input size: 30-50mm

Configure Equipment: Sand-making machine, modular structural parts

The sand-making machine module station is mainly used in the construction and non-mining industries to process and produce high-quality sand or granular materials.

Features

- With small vibration and low noise, it can produce high-quality sand with round particles and continuous and stable gradation.

- The structure is beautiful and simple. All independent workpieces can disassemble, which is convenient for assembly, disassembly, and transportation.

- It can equip with a hydraulic opening and closing or an electric lifting device, which is convenient for equipment maintenance.

- It can configure with a standardized intermediate silo and a modular unit capable of continuous and uniform feeding.

- Safety ladders, handrails, and platform passages are convenient for operators to check the sand-making machine.