Mobile Crushing & Screening Plants

Feeding Size: 0-750 mm

Capacity: 20-450 TPH

Application: Aggregate production, construction waste recycling, quarrying, mining industry.

Mobile Crusher Station Types: Wheel type mobile crushing station, crawler mobile crushing station

The mobile crushing & screening plant can be specially customized according to the requirements of the customer’s job site, material, grain type, etc., to provide customers with equipment that is more suitable for production needs.

Mobile Crushing & Screening Plants

Mobile crushing and screening plant capability provides high transportation speed and operation activity and is compatible with high production capacity. It is possible to collaborate with a portable crushing machine, which can be used independently to separate three types of grain size and can be used with a wheel-type loading machine, an excavator, or a crushing machine.

Protable crushing and screening stations can directly select, arrive at the site, provide unneeded transportation, and deliver product granularity. They are used for metallurgical, chemical, building materials, water, and electric power, etc., material processing for transporting constant demand, especially for high-speed highways, railways, water and electrical engineering, building construction, etc. Fluid material breakdown work, genuinely produced by customer manufacturing Low-production books with new commercial opportunities.

The mobile crushing station can not only operate independently as a single unit but also can combine into a two-stage crushing and screening system for coarse crushing and fine crushing and a three-stage crushing and screening system for coarse crushing, medium crushing, and fine crushing, or it can combine into crushing first and then screening or Sieve first and then crush the system. Its configuration is flexible, and the mobile crushing station can be specially customized according to the requirements of the customer’s job site, material, grain type, etc., to provide customers with equipment that is more suitable for production needs.

Mobile Crusher Station Types

Mobile Crushing Station Working Principle

The loading machine sends the raw materials to the warehouse and the materials enter into the vibrating feeder, then the feeder sends the material to the crusher. The belt conveyor sends the crushed material to the vibrating screening. After the screening, we get the fine finished material, and the big material sends the crusher for re-crushing.

Structure

- Mobile carriage

- Feeding machine

- Crushing machine

- Vibrating screen

- Belt conveyor

- Centralized electric control unit

- Electric cable

Crusher can be freely combined according to feed requirements.

Features

- 1. Equipped with high-performance box, low noise, and low emission.

- 2. Automatic system division operation coordination, system division efficiency is great.

- 3. Structured structure, good mobility, no special transport, large and low transport.

- 4. The configuration can select according to the needs of users. Different crushing and screening processes can form according to different crushing process requirements, and crushing and screening can also be used separately.

Mobile Impact Crusher Station

Mobile Jaw Crusher Plant

30TPH Mobile Stone Crushing Station

150TPH Mobile Crushing Plant

Wheel-type Mobile Crushing Plant

Wheel-type Mobile Jaw Crusher

Capacity: 20-450 TPH

Feed size: <750 mm

Output size: 15-165 mm

The mobile wheel jaw crusher is an integrated unit of equipment composed of a feeder, jaw crusher, conveyor belt, and other components. It can be operated on a stand-alone machine and go directly to the production site. The wheel mobile jaw crushing station is suitable for various materials such as cobblestone, limestone, quartz stone, granite, andesite, construction waste, briquette, raw coal, etc. And it is a very popular excellent equipment in the fields of mines, coal mines, building materials, environmental protection, water conservancy, and roads.

Wheel-type Mobile Cone Crusher

Capacity: 50-450 TPH

Feed size: <240 mm

Output size: < 40 mm

The mobile wheel-type cone crushing station adopts mobile grinding technology, which can meet the mobile crushing requirements of customers. It is mainly used for fine-crushing and operating mobile stone materials such as highways, railways, and hydropower projects. In the production of sand and gravel, according to different stones and finished products, The mobile cone crushing station is used to replace the impact crusher to produce sand with higher hardness and finer grain size stone products.

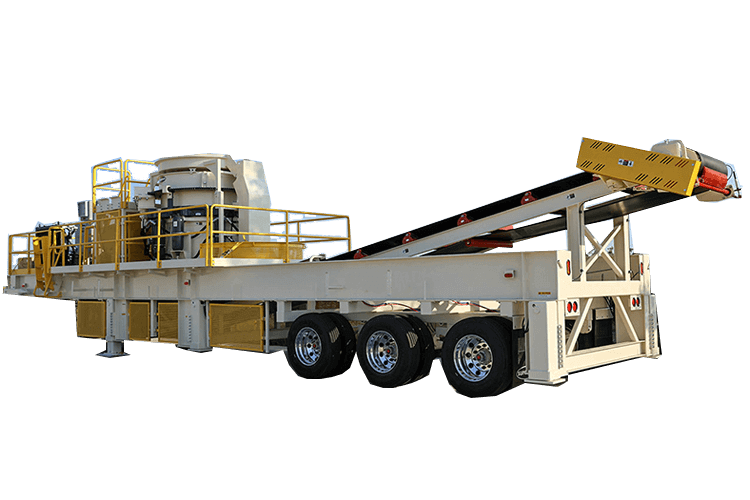

Wheel-type Mobile Impact Crusher

Capacity: 50-450 TPH

Feed size: <300mm

Output size: <50mm

The mobile wheel-type impact crushing station mainly uses for the processing of metallurgy, chemical industry, building materials, hydropower, and other materials that often need to be relocated, especially for the operation of mobile stones such as highways, railways, and hydropower projects. Users can adopt various configuration forms according to the type and scale of processing raw materials and the requirements of finished materials.

Crawler Mobile Crushing Plant

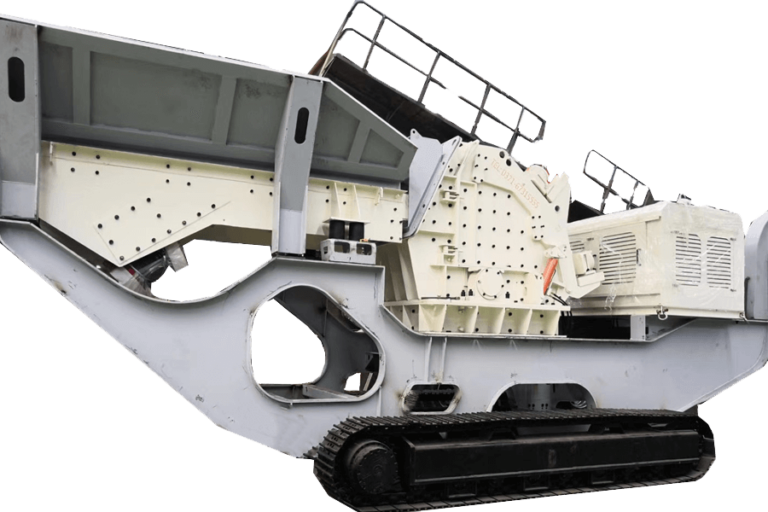

Crawler Mobile Jaw Crusher

Capacity: 20-450 TPH

Feed size: <750 mm

Output size: 15-165 mm

The mobile crawler jaw crusher adopts self-driven mode, has complete functions and a beautiful appearance, and can reach any position on the working site under any terrain conditions.

Crawler Mobile Cone Crusher

Capacity: 50-450 TPH

Feed size: <240 mm

Output size: < 40 mm

The mobile crawler cone crusher is a high-efficiency medium and fine crushing equipment. Its main engine is flexible in selection and can equip with a multi-cylinder hydraulic cone crusher and a single-cylinder hydraulic crusher. It is mainly used for secondary and tertiary crushing in river channel management, cobblestone crushing, construction waste disposal, and other site operations that require frequent relocation.

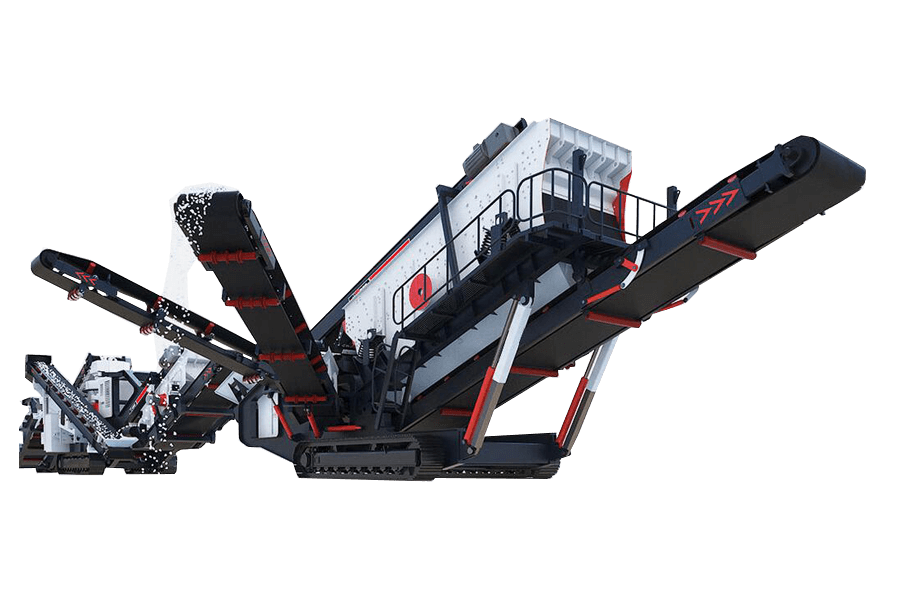

Crawler Mobile Impact Crusher

Capacity: 50-450 TPH

Feed size: <300 mm

Output size: <50 mm

The mobile crawler-type impact crusher is a multi-purpose mobile crushing equipment that adopts a crawler-type drive mode of oil-electric hybrid power. It is widely used in construction waste crushing, coal gangue, limestone, and other harsh crushing environments.

Main Technical Parameters

| Portable/Mobile Jaw Crusher | ||||||

| Model | Vibrating Grizzly Feeder | Jaw Crusher | Belt Conveyor | Capacity(t/h) | Power(kw) | Max size(L * W * H)(mm) |

| DN938P69 | DN380×95 | PE600×900 | B800×8M | 70-150 | 91.5 | 13200×2900×4700 |

| DN1142P710 | DN420×110 | PE750×1060 | B1000×11M | 90-200 | 134 | 15000×3100×5100 |

| DN1349P129 | DN490×130 | PE900×1200 | B1200×13M | 150-300 | 146 | 17000×3300×5600 |

| Portable/Mobile Impact Crusher | ||||||

| Model | Circle Vibrating Screen | Impact Crusher | Belt Conveyor | Capacity(t/h) | Power(kw) | Max size(L * W * H)(mm) |

| 3YD1848F1210 | 3YD1848 | PF-1210 | B650×7M | 70-300 | 128.5-150.5 | 12500×3000×6500 |

| 3YD1860F1214 | 3YD1860 | PF-1214 | B650×8M | 90-400 | 154-190 | 13500×3000×6500 |

| 3YD2160F1315 | 3YD2160 | PF-1315 | B800×8M | 120-450 | 210-297 | 14000×3200×6800 |

| Portable/Mobile Cone Crusher | ||||||

| Model | Circle Vibrating Screen | Cone Crusher | Belt Conveyor | Capacity(t/h) | Power(kw) | Max size(L * W * H)(mm) |

| 3YD1848DN10SX | 3YD1848 | DN1000S-X | B650×7M | 70-300 | 99-134 | 13000×3000×6700 |

| 3YD1860DN12SX | 3YD1860 | DN1200S-X | B650×8M | 120-400 | 212.5-220.5 | 14000×3000×6700 |

| 3YD2160HP200 | 3YD2160 | HP200 | B800×8M | 140-450 | 257.5-264.5 | 14000×3200×6700 |

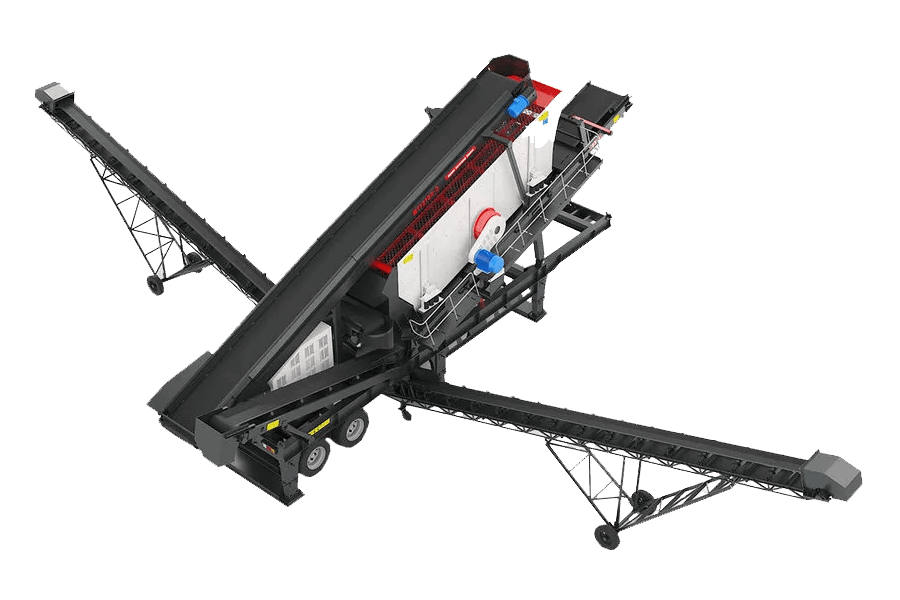

Mobile Screening Plant

Wheel Mobile Screening Station