X Ray Intelligent Photoelectric Sorter

Particle Size Range: 10-120 mm

Capacity: 30-160 t/h

Scope of Application: It is suitable for mining enterprises such as ore dressing plants, mining sites, slag and rock dumps, and gold treatment enterprises applied to the sorting of metallurgical production waste.

X Ray Intelligent Photoelectric Sorter Overview

The X-ray intelligent photoelectric sorter(also called X-ray intelligent ore sorting machine) is a mining equipment based on X-ray detection and artificial intelligence technology. With the application of X-ray intelligent pre-concentration technology, the feed grade of processed ore can be improved, a large amount of waste rock can be pre-discarded, and valuable minerals in tailings and slag can be recovered and reused, to reduce the processing cost of downstream processes (crushing, grinding, flotation, etc.), greatly improve the mine efficiency and economic benefits and extend the mining equipment life. lt can be widely used in all kinds of mines, including precious metals, nonferrous metals, and other minerals, such as gold, silver, molybdenum, copper, zinc, tungsten, vanadium, and so on. Metals, such as copper, zinc, and lead. Generally speaking, it is mainly used for pre-selection and discarding of ore to save comprehensive processing costs.

Sortable Ores

- Non-ferrous metal ores: antimony, gold, silver, copper, aluminum, lead, zinc, tungsten, molybdenum, tin, nickel, vanadium, titanium, etc.

- Ferrous ores: wolframite, iron, manganese, chromium, etc.

- Non-metallic ores: fluorite, magnesite, coal, gangue, etc.

- Others: phosphorite, perlite, solid waste, smelting slag, etc.

Core Technology

- Machine vision: Machine vision is to use machines to simulate human eyes to make measurements and judgments. Its basic feature is to improve the flexibility and automation of production. In some environments that are not suitable for manual work or where artificial vision cannot meet the requirements, machine vision can replace artificial vision to greatly improve production efficiency, production quality, and automation.

- High-performance computing and big data technology: It is difficult for a single feature of data to express the characteristics of the target. Multi-directional, multi-angle, and multi-level feature extraction and data fusion are performed for the detection target, and massive data sets are summarized. Combined with high-performance computing, the machine can describe the inherent characteristics of the detection target.

- Deep learning: Deep learning originates from the human brain. By simulating the analysis and learning mechanism of the human brain neural network, the low-level features are combined to form a more abstract high-level attribute category or feature model structure, allowing the machine to learn, analyze, and interpret target information like the human brain, and complete difficult recognition and evaluation tasks.

Advantages

X-Ray Intelligent Photoelectric Sorter Advantages

- High efficiency and accuracy: The equipment realizes high-speed sorting through the high-speed controller, which can process tens of thousands of materials per second, and adopts an advanced ray source and detector, which can accurately distinguish different kinds of materials.

- Intelligent operation: The integration of an advanced AI algorithm and an automation control system realizes intelligent sorting and remote monitoring, which improves production efficiency and makes equipment maintenance more convenient.

- Environmental protection and energy saving: Non-contact detection reduces dust pollution during ore crushing and grinding while reducing energy consumption and noise emission.

- High-precision identification: Grain-by-grain detection of ore particles by X-ray ensures the accuracy of sorting and improves the recovery rate and grade of ore.

- Composite identification technology: Combine X-ray, visible light, or infrared camera to carry out composite identification and further improve sorting precision.

- Real-time online monitoring: Using Internet of Things technology, real-time online monitoring of equipment operating status, fault prompts, and alarms, the system can be self-learning, updating, and constantly improve the efficiency of sorting.

Structures & Working Principle

X-Ray Intelligent Photoelectric Sorter Structure

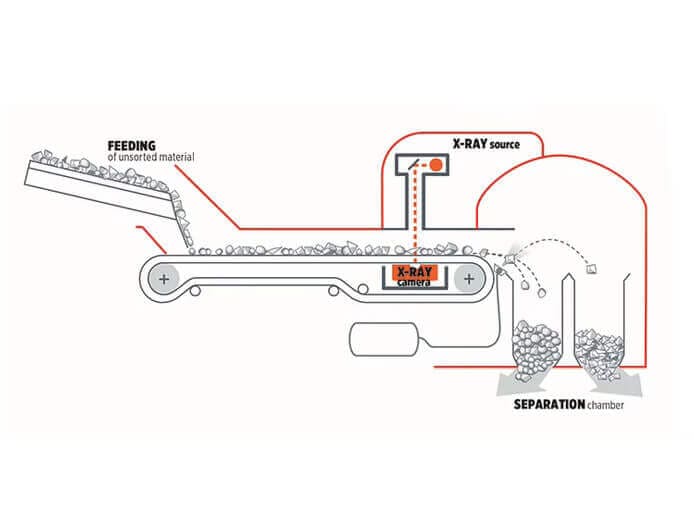

The main components of the intelligent ore separation machine, according to the structure of each part, can be divided into the following 4 parts:

- Feeding system: Convey the ore so that the ore enters the detection area steadily and stably.

- Detection system: It is the core part of the ore separation equipment.

- Signal processing system: High-speed processing of the characteristic information obtained by the detection system, using artificial intelligence algorithms to analyze and identify the ore images and data, and decide whether to spray the waste rock.

- Separation and execution system: The target ore can be sprayed away from the original route using the high-pressure gas discharge gun to achieve separation.

X-Ray Intelligent Photoelectric Sorter Working Principle

Based on the X-ray and sensor technology, the XRT intelligent photoelectric sorting machine queues the raw ore, scans the raw ore with X-rays, collects data from the detector uses sensors and big data analysis, and uses intelligent algorithms to identify ore and waste rock The waste gun sprays waste stone to realizing efficient automatic intelligent sorting.

Technical Parameters

| Model | X1400 | Customized products,consult for other models |

| Particle Size Range | 10-60 mm | |

| Capacity | 30-60 | |

| Recovery Rate | 98% | |

| Power | 20.5 kW | |

| Operation Cost | ¥1/t | |

| Size | 10978*2400*3243 MM |