VSI Sand Making Machine

Capacity: 20-180 m3

Feeding Size: ≤ 50mm

Power: 90-630 kW

VSI Sand Making Machine Overview

VSI sand-making machine is a model of sand-making equipment that combines mature fine crushing technology and mechanical manufacturing. Its advantages include an excellent sand-making effect, long life, high output, and smooth operation. Its unique rotor structure design, wear-resistant material technology, crushing speed optimization, and hydraulic design can provide high-quality sand and gravel aggregates for highways, high-speed railways, high-rise buildings, municipal construction, hydropower dam construction, and concrete mixing stations. It is ideal equipment for artificial sand making and stone shaping.

Application scope: Sand and gravel yard, concrete sand making, dry mortar, machine-made sand, power plant desulfurization, quartz sand, etc.

Applicable materials: River pebbles, granite, basalt, iron ore, limestone, calcite, quartz stone, diabase, etc.,

Features

- Material throughput increased by 30%

A new design of four throwing ports and an optimized deep cavity rotor.

- Reduced production costs

Adopt the “stone against stone” working mode to reduce the types of wear-resistant applications.

- The product-shaping effect increased by 30%

The stones have good grain shape, are polyhedral, and have reasonable gradation.

- Dual linkage protection of control system and lubrication system

Complementary oil supply by dual oil pumps; automatic shutdown without oil flow; air-cooled cooling; self-starting heating in winter.

Advantages

VSI Sand-Making Machine Advantages

- Convertible to multiple feeding methods

It can quickly realize the conversion between the two complete center and center feeding modes with waterfall feeding. It can also quickly realize the conversion of “stone on stone” and “stone on iron.” One machine has multiple functions that adapt to different user requirements, such as gravel and plastic surgery. - The fineness modulus can be adjusted.

The fineness modulus is adjustable and controllable. The product has excellent grain shape, cube shape, low needle flake content, high packing density, uniform gradation, and low iron pollution. It is suitable for aggregate shaping, artificial sand making, and high-grade highway aggregate production. - Automatic detection is safe and reliable.

Equipped with an excessive vibration display and alarm device, if the equipment malfunctions, a warning can be issued to stop the equipment to protect the equipment. - Environmentally friendly and less polluting

The unique air circulation system greatly reduces the amount of external exhaust air, reduces dust pollution, and benefits environmental protection. In addition, the reserved position of the crusher is also suitable for installing various specifications of dust removal equipment.

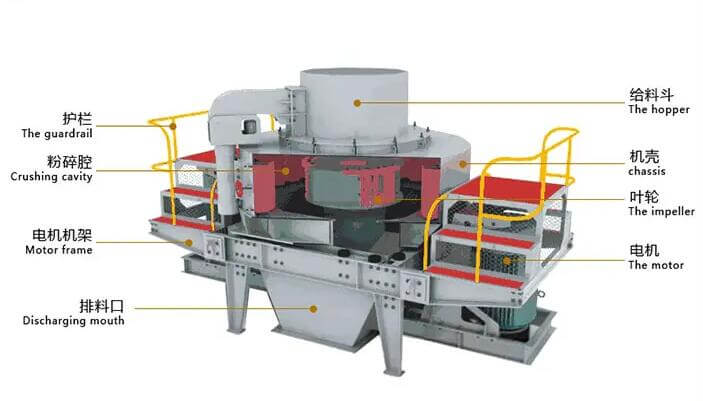

Structures & Working Principle

VSI Sand Making Machine Structure

VSI vertical sand-making machine consists of a chassis, rotor, spindle device, cooling device, motor, transmission pulley, and electric control cabinet.

- Chassis: The casing is the skeleton of the VSI vertical sand-making machine. The lower part is the discharge port, the middle is the impact crushing chamber, and the top is the feeding port. Its function is not only to be used as a feeding support but also to adjust the flow direction and flow rate of the circulating air volume. Generally, there is an inspection door on the casing to facilitate daily observation, equipment maintenance, and lining replacement.

- Rotor: The rotor used in the VSI vertical sand-making machine is an automatically protected rotor, different from ordinary cylindrical rotors. It is an equilateral triangular component centered on the rotating shaft. It has three discharge ports. Each discharge port is equipped with a protective plate to prevent most of the rebounded materials from impacting the side of the rotor. On the one hand, this plate protects the surface of the rotor; on the other hand, it improves the material properties.

- Spindle device: The spindle device of the sand-making machine is a vertical shaft supported on two bearings and driven by a belt conveyor.

- Lubrication and cooling device:This sand-making machine uses special thin oil spray lubrication, and the lubrication effect is good.

- Electric motor and belt drive: The electric motor is an ordinary motor used in conjunction with the belt drive.

VSI Sand Making Machine Working Principle

The materials fall into the crushing chamber from the feed hopper. The main shaft rotates at high speed, driven by the motor through the lower V-belt, which drives the hollow rotor installed on the upper end of the main shaft to rotate together. The materials are added to the center of the rotor from the top center feeding port and are then divided. The cones are divided into three discharge chambers. The centrifugal force of the high-speed rotation of the rotor accelerates the material. It is thrown out at a very high linear speed when passing through the discharge port. It collides with the annular impact surface formed by the surrounding material cushion or counterattack lining. The material particles are thrown at a very high speed. Under the action of impact speed, it is decomposed into small cube-shaped particles along the original natural cracks. At the same time, the strong airflow generated during rotation returns from the crushing chamber to the central feeding port, forming an internal circulation within the machine, which prolongs the residence time of materials in the crushing chamber and enhances the grinding effect of fine particles. As the centrifugal impact process continues to break, the particles of the broken materials collide violently and rub against each other, making the materials evenly refined. The crushed materials have fine particles and high acceptable powder content, a crushing effect that other sand-making machines cannot achieve.

Technical Parameters

| Model | Max Feeding Size | Through Put(m3) | Capacity(m3) 【Soft Material+10%】 | Speed of Main Shaft (r/min) | Power(kW) | Dimension(mm) |

| DN-5000 | 35mm | 40-60 | 20-35 | 1700-1890 | 90 | 3800*2180*2425 |

| DN-6000 | 35mm | 60-80 | 30-40 | 1560-1720 | 160 | 4240*2200*2778 |

| DN-7000 | 40mm | 100-120 | 40-50 | 1550-1650 | 132*2 | 4700*2200*2850 |

| DN-8000 | 40mm | 160-200 | 64-80 | 1400-1720 | 160*2 | 5200*2250*3250 |

| DN-8500 | 45mm | 180-200 | 72-80 | 1400-1720 | 200*2 | 5200*2350*3250 |

| DN-9000 | 45mm | 220-250 | 80-96 | 1510-1650 | 250*2 | 5200*2450*3250 |

| DN-9500 | 45mm | 250-270 | 96-108 | 1510-1650 | 280*2 | 5200*2250*3450 |

| DN-10000 | 50mm | 270-350 | 120-180 | 1480-1600 | 315*2 | 5200*2250*3450 |

| Note: The above capacity is based on the loose specific gravity of 1.6t/m3 rock stone | ||||||