Vibratory Sand Screening Machine With Conveyor

Capacity: 0-200 T/H

Screen & Mesh Size: Customization

Motor Power:

Main motor: 4-11 kW;

Screen motor:4-7.5 kW;

Vibration Motor: 0.5 kW

Application: Sand and gravel separation, cinder separation, ore separation, construction sites, sand fields, road and bridge projects, grain depots, etc.

Vibratory Sand Screening Machine With Conveyor Overview

The sand screening machine, a dry land sand screening boat, is suitable for sand and gravel separation equipment in rivers, reservoirs, and coal fields. The vibrating screen sand screening machine is an important construction equipment used to screen and separate gravel of different sizes. Its function is to screen and classify gravel in the production process of building materials to obtain gravel of different particle sizes. The emergence of the vibrating sand screening machine has replaced the problem of slow manual sand screening, saved a lot of human resources, improved the efficiency of sand screening, and can fully meet people’s requirements for sand screening.

Features

- Due to the strong vibration of the screen box, the vibrating screening machine reduces the phenomenon of materials blocking the screen holes, making the screen have higher screening efficiency and productivity.

- The structure is simple, and the screen surface is easily replaced.

- Screening consumes less electricity per ton of material.

- Can perform multi-layer screening and classification with good effect

The mobile vibrating sand screening machine is a sand mining machinery separating coarse and fine materials. It has fast sand production speed, uniform material discharge, high reliability of the whole machine, low one-time investment, high screening efficiency, and long service life by using a special screen. The distinctive feature of the mobile vibrating sand screening machine is its mobility, which usually has wheels or tracks and can be easily moved between construction sites or mining sites to adapt to different tasks and location requirements. This type of equipment is typically used in applications that require the movement and handling of sand, gravel, or other granular materials, such as construction sites, mining sites, or concrete batching plants.

The mobile vibratory sand screening machine with a conveyor is a multi-functional equipment with a complex structure. It consists of multiple components such as a vibrating screening part, a conveying part, a support structure, a control system and moving parts to achieve the screening of granular materials such as sand and gravel. It has a wide range of uses. One machine is multi-purpose and can process a variety of sizes and shapes. It is efficient, energy-saving, sturdy and durable.

Advantages

Vibratory Sand Screening Machine With Conveyor Advantages

- High-cost performance: This machine uses equipment with low investment and quick results. It can quickly withdraw funds.

- Less labor consumption: This ends the history of sand screening machines consuming labor.

- High sand production rate: The stones screened out by the manual sand screening machine contain 10% effective sand, and the sand production rate of this machine is 100%, which greatly improves the economic benefits.

- Fast screening speed: This machine can screen 16-18 tons of sand per hour, while manual screening can sift 1-2 tons of sand per hour, more than ten times that of manual screening.

- Strong screening ability: no matter how high the water content is, it can be screened normally, ending the history of difficulty in screening due to high water content.

- Easy to use and labor-saving: This machine has a low feeding height & agile movement, is small in size, lightweight, and easy to operate, and is suitable for various construction sites.

- Scope of application:Suitable for large and small construction sites, coal yards, grain, artillery factories, foundries, flower nurseries, medicinal materials, construction mortars, etc.

- Mobility:Equipment can be equipped with wheels or tracks and quickly move to different working positions to adapt to different project needs.

- Multi-functional integration: The mobile vibrating screen sand conveying machine integrates vibrating screening and conveying functions into one, reducing the equipment’s floor space and improving work efficiency.

Structures & Working Principle

Vibratory Sand Screening Machine With Conveyor Structure

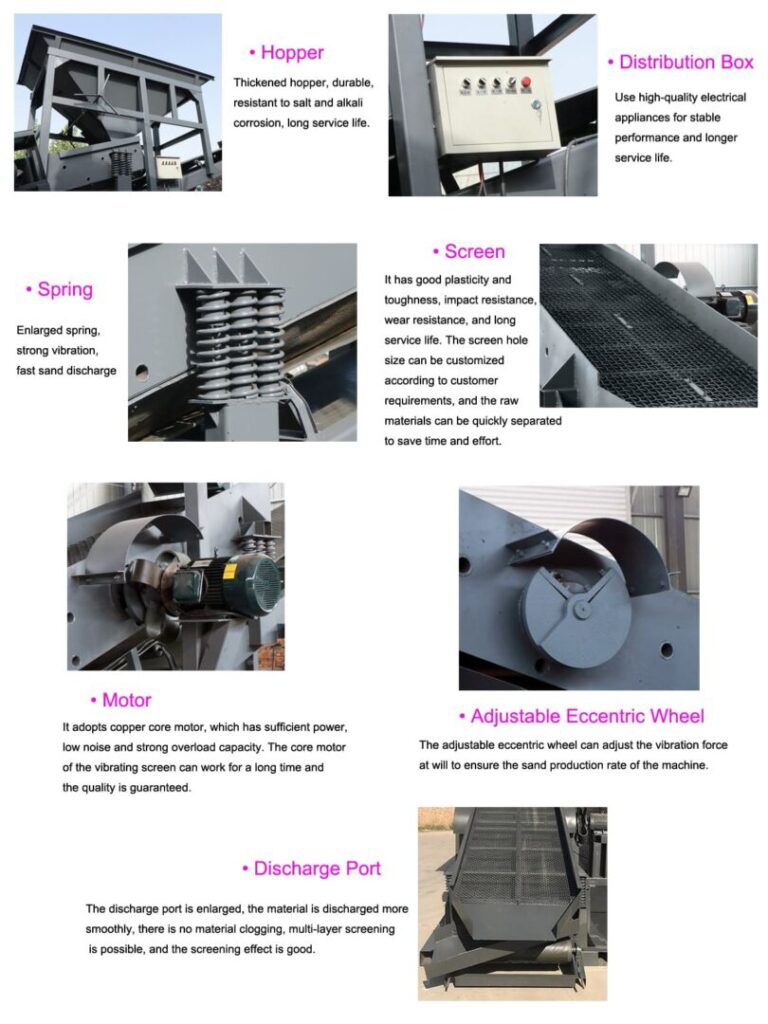

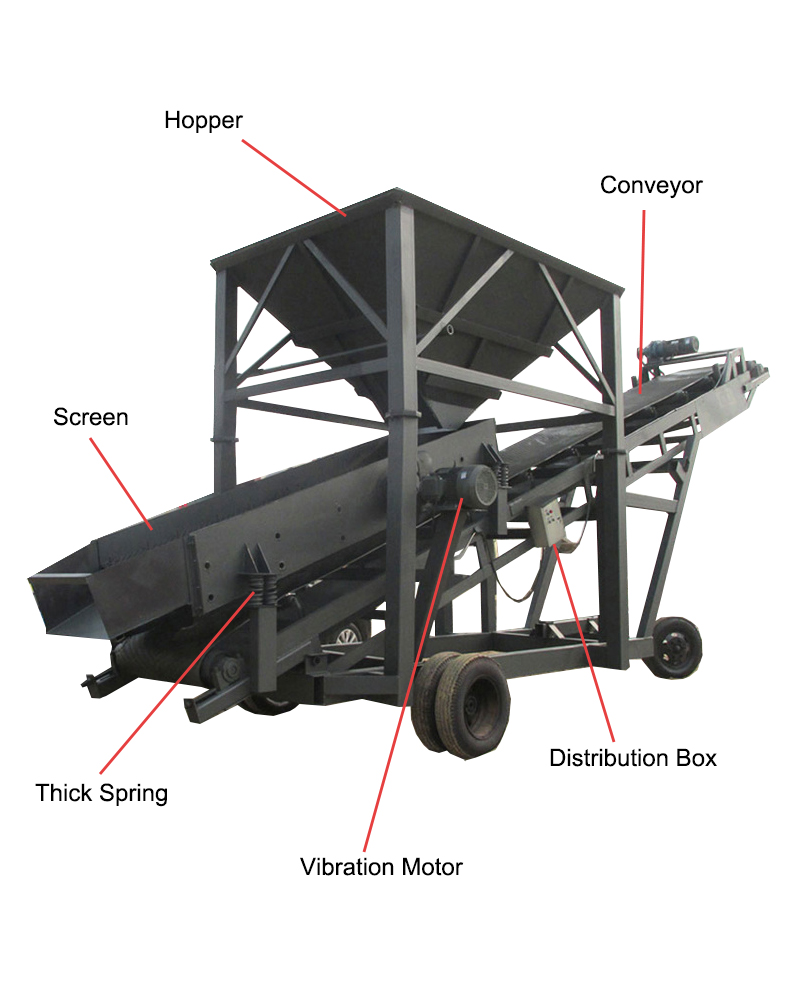

The main structural components of the mobile vibration sand screening & conveying machine including:

- Vibrating screening part– vibrating screen machine: screen box, motor, vibrator

- Conveying part: conveyor belt

- Architecture and support structures: support frames, columns, legs, and other support elements

- Control system: The control system includes electrical control and operation panels for starting, stopping, adjusting vibration force conveying speed, etc. These control functions usually include electrical components, sensors, and control panels.

- Moving parts: such as wheels or tracks

Vibratory Sand Screening Machine With Conveyor Working Principle

The working principle of the mobile vibrating screen sand conveying machine involves two main processes: screening and conveying.

Screening Process

- Particle input: First, the sand and gravel particles to be screened are loaded into the screen box of the vibrating screen machine.

- Vibration mechanism: The vibration mechanism in the equipment (usually composed of a motor and a vibrator) starts to work and generates vertical or horizontal vibration force. These vibration forces cause the screen box and screen mesh to vibrate.

- Screening process: The vibration force is transmitted to the screen box and screen mesh, causing the particles to move and vibrate on the screen mesh. Due to the different sizes and shapes of the particles, it separates the materials on the screen based on differences in size and weight. Smaller particles pass through the screen holes into the next layer of the screen or the conveyor belt below, while the larger particles stay on the screen.

- Classification: If the equipment is equipped with a multi-layer screen, the particles will be classified at different levels to obtain sand and gravel particles of the required size.

Conveying Process

- Conveyor belt: The conveyor belt at the bottom starts running and transports the screened particles from the bottom of the screen box to the target location. Motors usually drive conveyor belts to ensure the particles move at the desired speed and direction.

- Conveying pellets:Conveyor belts transport pellets along a specific path to a stacking area, transport equipment, or other destination location. The speed of the conveyor belt can be adjusted as needed to meet job requirements.

In general, the working principle of the mobile vibrating screen sand conveying machine is to achieve screening and classification of particles through the vibrating screening part and then transport the screened particles to the target location through the conveying part. The working principle of this equipment makes it suitable for sand and gravel production, construction, excavation, and other granular material processing applications, which can effectively improve production efficiency and material quality. Equipment models may differ regarding working principles and performance but generally follow the above mentioned principles.

Technical Parameters

| Model | JXSC-V20 | JXSC-V30 | JXSC-V50 | |

| Capacity | M3/H | 30-40 M3/H | 60-80 M3/H | 150-200 M3/H |

| T/H | 50-120 T/H | 80-160 T/H | 100-200 T/H | |

| Motor Power | Main Motor | 4 kW | 7.5 kW | 11 kW |

| Screen Motor | 4 kW | 4 kW | 7.5 kW | |

| Vibration Motor | 0.5 kW | |||

| Rated Voltage | 380 V | |||

| Hopper Size | 2*1 M | 3.2*1.5 M | 3.8*1.6 M | |

| Conveyor Belt | 4*0.6 M | 8*0.8 M | 9*1 M | |

| Screen Size | 1.5*0.6 M (customizable) | 3*0.8 M (customizable) | 3*1.2 M (customizable) | |

| Mesh Size | 10 MM (customizable) | |||

| Dimensions | 4.2*1.1*2.2 M | 8.3*1.6*3.2 M | 9.2*1.9*3.4 M | |

| Weight | 550 KG | 1500 KG | 2000 KG | |