Home » Equipment » Auxiliary Equipment » Vibrating Feeder

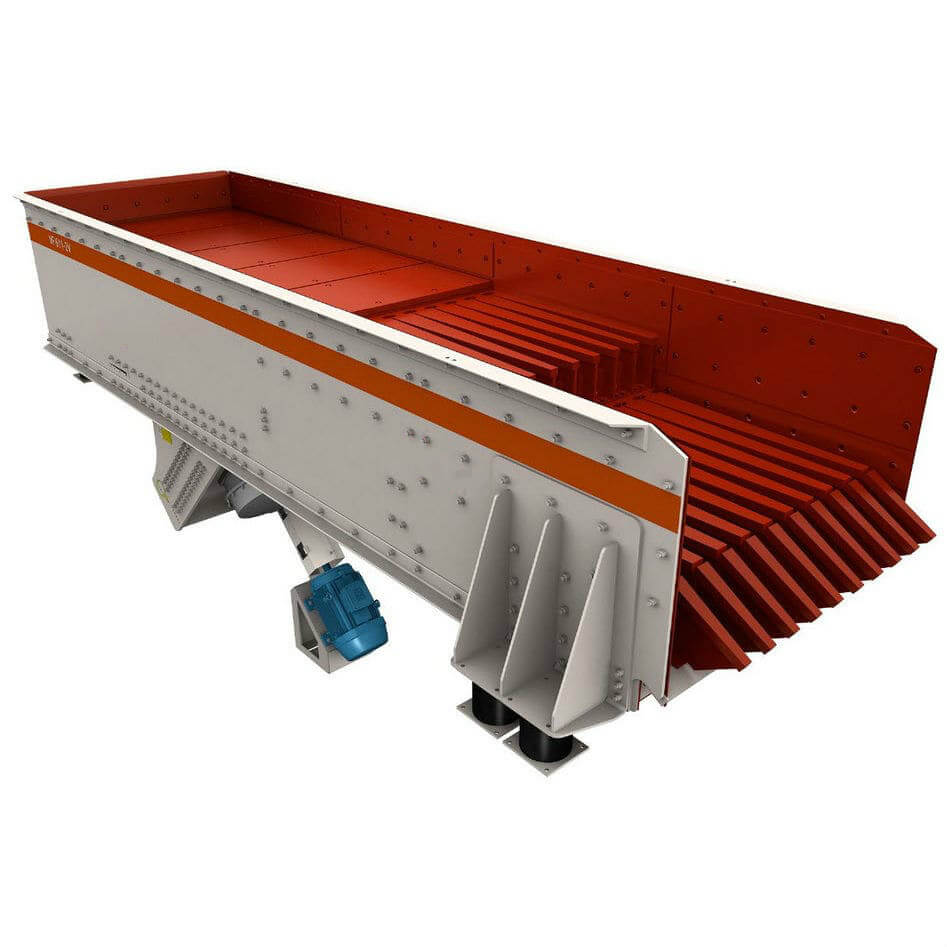

Vibrating Feeder

The vibrating feeder is an automated device that uses the principle of vibration to achieve continuous and uniform material conveying. It is widely used in the feeding, screening, and conveying of granular or powdered materials in industries such as mining, metallurgy, building materials, chemicals, and food.

Capacity: 96-1200 T/H

Process Material: Ore, coal, aggregate, concrete, artificial sand, quartz sand, and so on.

Vibrating Feeder Overview

The vibrating feeder is widely used in metallurgy, mineral processing, building materials, chemical, abrasive, and other industries in crushing and screening equipment. It is used for conveying ferrous or non-ferrous metal ore and building materials; it is not suitable for conveying sticky wet material.

Our vibrating feeder is an instrument that uses vibration to “feed” material to a process or machine. Our vibratory feeders use both vibration and gravity to move material: Gravity is used to determine the direction, either down or down and to a side, and then vibration is used to move the material.

The vibrating feeder is designed to convey bulk materials uniformly before the coarse crusher for crushing and screening.

Vibrating Feeder Types

The vibrating feeder can be divided into the steel plate structure and the grating structure. The Steel Plate Structure Feeder is mostly used in the sand and stone production line, the material can be uniformly fed into the crushing equipment, the Grate Structure Feeder can coarse screen the material, it makes the system more economical and reasonable, and has been used as essential equipment in crushing and screening.

Advantages

The vibrating feeder offers compact size, lightweight design, and simple construction for easy installation and low-cost maintenance while delivering high-efficiency performance with large feeding capacity. It operates with minimal noise pollution to improve working conditions, features low energy consumption with excellent power factor, and enables convenient stepless feeding adjustment through eccentric block control. The dual-shaft vibrator and linear vibration mechanism ensure stable, reliable operation with extended service life while simultaneously performing feeding and screening functions. With straightforward automatic control integration, this equipment finds wide applications across mineral processing, building materials, silicate production, and chemical industries.

Vibrating Feeder Advantages

✔ Precise and controllable: Feeding rate is controlled by adjusting the amplitude/frequency (accuracy ±2%).

✔ Energy-efficient: Energy consumption is reduced by 30-50% compared to belt conveyors.

✔ Adaptable: Capable of conveying high-temperature (≤300°C), corrosive, and sticky materials.

✔ Low-maintenance: No transmission parts wear, with a lifespan of 5-10 years.

✔ Multifunctional integration: Can combine screening and metering functions (such as a quantitative feeder).

Structures & Working Principle

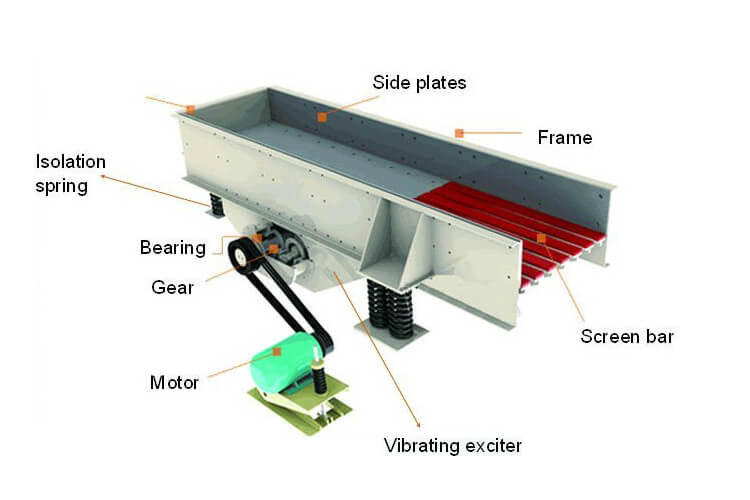

Vibrating Feeder Structure

The vibrator is composed of two specific locations of the eccentric shaft gear meshing, the assembly must be marked by the two gear meshing, driven by the motor, the two eccentric shaft rotation, resulting in huge linear vibration synthesis, so that the body for forced vibration in the spring, then vibration material as a driving force, slip and throwing motion in the trough, so that the material forward to achieve the purpose of feeding. When the material is through the slot on the screen strip, the smaller material can fall through the sieve gap, not through the next crushing, the screening effect.

Technical Parameters

| Vibrating Feeder Parameter | ||||||

| Model | Size of Funnel(mm) | Max Feeding Size(mm) | Feeding Capacity(t/h) | Motor Power(kW) | Dimensions(mm) | |

| DN380*95 | 3800×950 | 500 | 96-160 | 11 | 3882*2224*2121 | |

| DN490*95 | 4900×950 | 500 | 120-240 | 15 | 4957*2277*2150 | |

| DN490*110 | 4900×1100 | 580 | 120-280 | 15 | 4957*2400*2150 | |

| DN590*110 | 5900×1100 | 600 | 200-350 | 22 | 6000*2500*2150 | |

| DN600*130 | 6000×1300 | 750 | 400-560 | 22 | 6082*2580*2083 | |

| DN600*150 | 6000×1500 | 1000 | 800 | 30 | 6627*2350*3068 | |

| DN600*200 | 6000×2000 | 1000 | 1200 | 37 | 6436*3853*3014 | |