Vertical Ring High Gradient High Intensity Magnetic Separator

Capacity: 0.01-150 TPH

Feeding Size: 0-1.2 mm

Feeding Material Density: 10-30%

Background Magnetic Field: 0.6-1.4 T

Vertical Ring High Gradient High Intensity Magnetic Separator Overview

Vertical Ring High Gradient Magnetic Separator is an efficient magnetic separation equipment mainly used to separate and purify magnetic minerals. It uses different magnetic substances to separate minerals and is widely used in ferrous, non-metallic, and other fields. This equipment separates minerals through the action of a magnetic field. It has the characteristics of a good separation effect and small separation fluctuation. It is an important equipment mining enterprises use for mineral processing.

Vertical ring high gradient magnetic separator is the strongest magnetic equipment with the best performance and state-of-the-art technology at home and abroad. This equipment fundamentally solved the blocking problem of horizontal ring magnetic separator & high gradient magnetic medium, with advantages of high concentration ratio, strong adaptability to feeding ore granularity, density and grade fluctuation, reliable operation, easy maintenance, etc. Achieving concentrate ore with high grade and recovery rate by picking weak magnetic ore.

Features

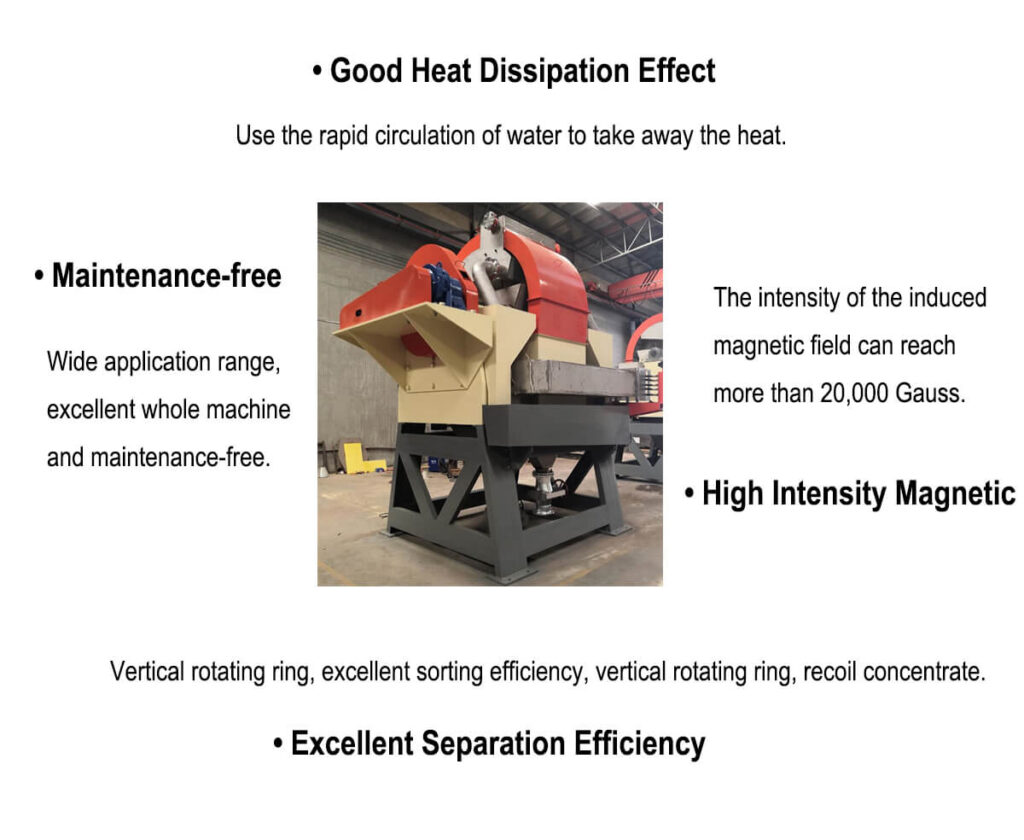

- Reliable and maintenance-free: The machine is reliable and has a wide range of applications.

- Good heat dissipation effect and more stable magnetic field: The excitation coil uses a thick hollow tube conductor, and the water flow directly passes through the center of the hollow tube conductor. The coil’s heat is directly transferred to the water, and the rapid circulation of the water flow removes the heat.

- Strong induced magnetic field: In this unique magnetic medium, the intensity of the induced magnetic field can reach more than 20,000 Gauss.

- Vertical rotating ring, high separation efficiency: Rotating ring, vertical rotation, backflush concentration. Solved the global problem of magnetic media clogging in flat ring high intensity separators.

Application Range

- Ferrous Metals: Martite, hematite, siderite, chromite, ilmenite, manganese, etc.,

- Non-Ferrous Metals: Wolframite, quartz, pyrrhotite, cassiterite, limonite purifying, scheelite, wolframite, garnet, etc.,

- Rare Earth: Tantalum and Niobium, lepidomelane, monazite, etc.,

- Non-Metals: Quartz, feldspar, kaolin for ceramics, sillimanite, cassiterite, andalusite, kyanite for refractory, separating impurities from hornblende, mica, tourmaline, garnet, etc.,

Advantages

Vertical Ring High Gradient Magnetic Separator Advantages

High separation efficiency: Due to high gradient magnetic field technology, the magnetic separator has a high magnetic field strength and can effectively separate fine and weakly magnetic minerals.

Low energy consumption: The unique structural design and optimized magnetic field gradient distribution reduce the energy consumption of the equipment and achieve significant energy-saving effects.

Compact structure: The vertical ring structure gives the magnetic separator a smaller footprint and makes it easy to install and maintain.

Easy operation: The degree of automation is high, and the operator can adjust the equipment according to actual needs, making the magnetic separation process more convenient and efficient.

Structures & Working Principle

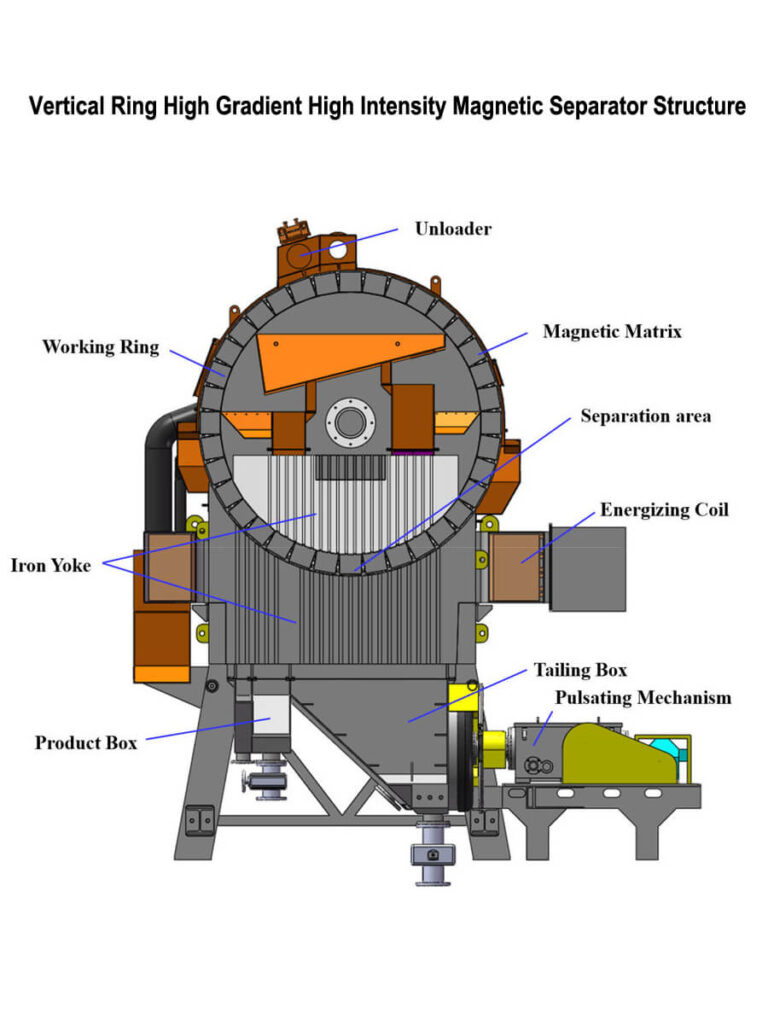

Vertical Ring High Gradient Magnetic Separator Structure

The main structural components of the vertical ring high gradient magnetic separator include the following parts:

- Vertical ring magnet: It is the core component of the magnetic separator and is responsible for generating a high-gradient magnetic field. Vertical ring magnets are generally made of permanent magnet materials or electromagnets.

- Separation ring: Located inside the vertical ring magnet, it forms a magnetic field gradient to capture and desorb magnetic particles.

- Screen:The screen is located in the separation ring and is used to carry mineral particles. When the magnetic field gradient acts on the mineral particles, the magnetic particles are adsorbed on the screen, separating magnetic minerals from non-magnetic minerals.

- Transmission device:responsible for driving the rotation of the separation ring and adjusting the magnetic separation speed to meet the separation needs of different mineral particles.

- Control system: Responsible for monitoring and adjusting various parameters of the magnetic separator to ensure stable equipment operation.

The working principle of the vertical ring high gradient magnetic separator is mainly based on the magnetic field gradient and the magnetic difference between mineral particles. By generating a strong magnetic field, the magnetic mineral particles are attracted to the magnetic separator’s screen due to the magnetic field’s force. In contrast, the non-magnetic minerals continue to fall through the screen. After the magnetic field disappears, the magnetic mineral particles adsorbed on the screen fall off, thereby effectively separating magnetic and non-magnetic minerals.

Vertical Ring High Gradient Magnetic Separator Working Principle

The working principle of the vertical ring high gradient magnetic separator is mainly based on the magnetic field gradient and the magnetic difference between mineral particles. By generating a strong magnetic field, the magnetic mineral particles are attracted to the magnetic separator’s screen due to the magnetic field’s force. In contrast, the non-magnetic minerals continue to fall through the screen. After the magnetic field disappears, the magnetic mineral particles adsorbed on the screen fall off, thereby effectively separating magnetic and non-magnetic minerals.

Technical Parameters

| Model | Background Magnetic Field (T) | Feeding Material Size (mm) | Feeding Material Density | Dry Ore Capacity (t/h) | Pulp Throughout (m3/h) | Excitation Power (kW) | Swivel Power (kW) | Pulsating Power (kW) | Swivel Diameter (mm) | Water Consumption (m3/h) | External Dimensions |

| LH-500 | 0.6-1.4 | 0-1 | 10-30% | 0.01-0.05 | 0.25-0.5 | 6-20 | 0.18 | 0.55 | 500 | 0.65-1.4 | 1800*1400*1320 |

| LH-750 | 0.6-1.4 | 0-1 | 10-30% | 0.1-0.25 | 1-2 | 8-30 | 0.75 | 1.5 | 750 | 1.4-2.5 | 2000*1360*1860 |

| LH-1000 | 0.6-1.4 | 0-1.2 | 10-30% | 2-4 | 12.5-20 | 10-40 | 1.1 | 2.2 | 1000 | 8-12 | 2700*2000*2400 |

| LH-1250 | 0.6-1.4 | 0-1.2 | 10-30% | 5-10 | 20-50 | 12-50 | 1.5 | 3 | 1250 | 12-20 | 3200*2340*2700 |

| LH-1500 | 0.6-1.4 | 0-1.2 | 10-30% | 10-15 | 50-100 | 15.5-60 | 3 | 3 | 1500 | 20-30 | 3600*2900*3200 |

| LH-1750 | 0.6-1.4 | 0-1.2 | 10-30% | 15-20 | 75-150 | 23-72 | 4 | 4 | 1750 | 30-50 | 3900*3300*3800 |

| LH-2000 | 0.6-1.4 | 0-1.2 | 10-30% | 20-30 | 100-200 | 29-85 | 5.5 | 7.5 | 2000 | 50-100 | 4200*3550*4200 |

| LH-2500 | 0.6-1.4 | 0-1.2 | 10-30% | 45-60 | 200-400 | 37-98 | 11 | 11 | 2500 | 100-150 | 5800*5000*5400 |

| LH-3000 | 0.6-1.4 | 0-1.2 | 10-30% | 80-120 | 350-650 | 48-110 | 18.5 | 18.5 | 3000 | 150-250 | 7600*6500*7200 |

| LH-3600 | 0.6-1.4 | 0-1.2 | 10-30% | 100-150 | 500-750 | 72-180 | 30 | 30 | 3600 | 200-400 | 7700*6500*7600 |