Tailings Blanket Recycling Machine

Capability: 1.5-2.5 t/h

Feeding Size: <0.5 mm

Voltage: 380 V

Output Power: 0.37 kw

Tailings Blanket Recycling Machine Overview

The tailings blanket recycling machine is a new type of gravity separation equipment, suitable for the purification of various rare metal ores (tungsten, tin, gold, copper, lead, zinc, chromium, titanium, zirconium, rare earth, monazite, tantalum niobium, garnet, quartz, kaolin). Compared with traditional gravity separation equipment, tailings blanket recycling machine has the advantages of high concentration efficiency, convenient adjustment, and management, and can obtain final concentrate and final tailings at one time.

Features

- Made of thickened steel, it is durable and not easy to wear out.

- The process is mature, the stress points are thickened and reinforced, and the service life is long.

- It is suitable for the purification of various rare metal ores (tungsten, tin, gold, copper, lead, zinc, garnet, quartz, and kaolin) and other products.

- In gravity separation, it has a high ratio of rich ore, easy to select and supervise, and easy to adjust.

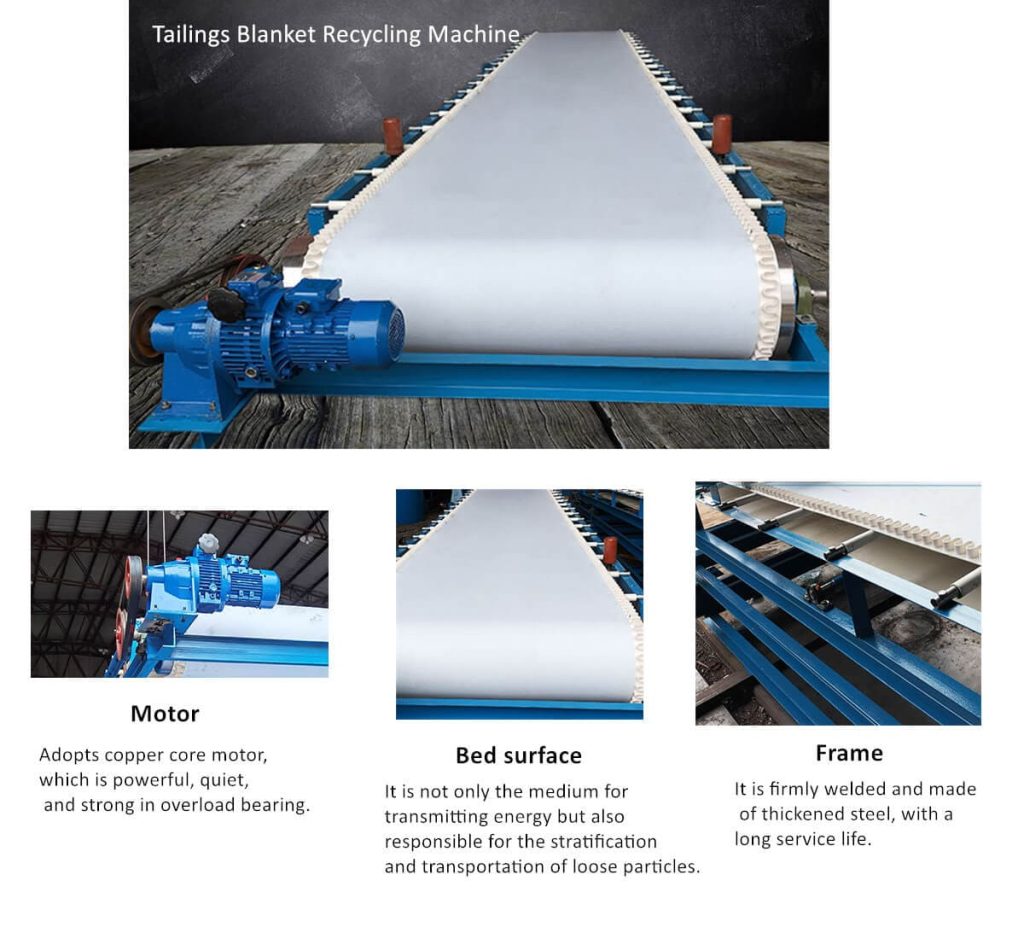

Product Details

- Motor

Adopts a copper core motor, which is powerful, quiet, and strong in overload bearing. - Bed surface

It is not only the medium for transmitting energy but also responsible for the stratification and transportation of loose particles. - Frame

It is firmly welded and made of thickened steel, with a long service life.

Advantages

Tailings Blanket Recycling Machine Advantages

- The tailing recovery machine occupies a small area, but it has a big work area with high capacity and a high recovery rate which will greatly reduce costs, improve profits, and save resources.

- Compared with traditional gravity separation equipment, the tailings blanket recycling machine has the advantages of a high ore enrichment ratio, high separation efficiency, easy supervision, convenient adjustment, and the ability to obtain concentrate and tailings at one time in gravity separation.

- The tailings recovery device can effectively reduce the loss of tailings, control it below 3% (calculated by volume), effectively reduce the content of effective components in the tailings water, and effectively solve the pollution of tailings to the environment, meeting the emission standards required by environmental protection.

- The tailings are fully recovered, reducing the workload of the sedimentation tank, and thereby reducing the cost of cleaning the sedimentation tank. In addition, the natural stacking time of tailings is reduced, and they can be directly transported and supplied to the market, further reducing operating costs.

Structures & Working Principle

Tailings Blanket Recycling Machine Structure

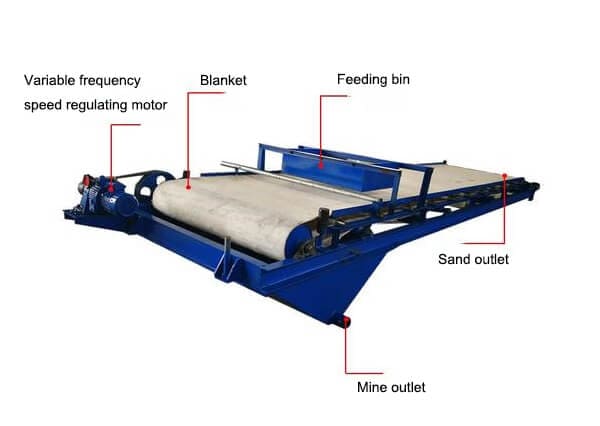

The basic structure of the tailings vibrating blanket concentrator includes a vibrator, a blanket, a bracket, and an adjustment device.

- Vibrator: Used to generate periodic vibrations, it is the core component of the vibrating blanket concentrator. Through the operation of the vibrator, the entire device can vibrate according to the set frequency and amplitude.

- Blanket: Carrying the minerals to be separated, the vibration of the blanket is used to separate minerals of different densities.

- Bracket: Supports the structure of the entire equipment to ensure the stability and safety of the equipment.

- Adjustment device: The vibration amplitude and frequency of the equipment can be adjusted as needed to meet different separation requirements.

These components work together to enable the vibrating blanket concentrator to effectively separate minerals of different densities and are widely used in the field of mineral processing.

Tailings Blanket Recycling Machine Working Principle

On the principle of the traditional belt conveyor, a layer of gold sticking cloth is added, so that the gold sticking cloth rotates continuously for 24 hours, achieving the purpose of replacing the gold sticking cloth every second for 24 hours. When the part with gold flakes on the surface is rotated to the bottom, it is impacted by recoil water to make the gold fall into the treasure bowl. This machine is suitable for the recovery of various metal ores, especially for the recovery of run-off ores.

Technical Parameters

| Dimensions(mm) | 1400*5000*850 |

| Capability (t/h) | 1.5-2.5 |

| Feeding Size (mm) | <0.5 |

| Feeding Density | 5-25% |

| Feeding Hopper | Controlled Hopper |

| Voltage (V) | 380 |

| Output Power (kw) | 0.37 |

| Output Speed (r/min) | 4-40 |

| Slope Adjust | 1-30° |

| Water Consume (t/h) | 0.7-1 |

| Working Surface | Special wear-resistant and easy to catch carpet |

| Beneficiation Area(Square) m2 | 4.8 |