Home » Equipment » Gravity Separation Equipment » Suspension Cone Shaking Table

Suspension Cone Shaking Table

The suspension cone shaking table (also known as a suspended vibrating cone concentrator or suspended vibrating cone shaker) is an advanced gravity concentrator that combines centrifugal force, gravity, and vibration separation. It is mainly used for the efficient enrichment and separation of fine-grained minerals. The equipment significantly improves the efficiency of mineral separation through multi-dimensional composite motion, and is particularly suitable for the refined recovery of low-grade heavy minerals (such as tungsten, tin, gold, and iron ore).

Capacity: 8-15 t/d

Feeding Size: 0.010-0.074 mm

Feeding Concentration: 15%-25%

Power: 1.5kW

Suspension Cone Shaking Table Overview

The suspended cone shaker(suspension cone shaking table) is a mineral processing equipment, mainly used for fine-grained mineral separation in gravity separation. It uses the density difference of mineral particles to achieve separation by vibrating and suspending the slurry on the conical table. This equipment has a high separation efficiency when processing fine and micro-fine materials, and is particularly suitable for processing precious metal ores such as gold, tin, and tungsten.

Features

- The tower structure is adopted in the suspension cone shaking table global design, is convenient for processing and transportation, and later maximization assurance is provided.

- The gradient of the diameter of the sorting card and sorting card, both reasonable in design, coupling make the disposal ability of equipment big, sorting washing water yield consumption is few.

- Low-speed rotation, dither two big kinematic systems are separate and the design that connects each other; Not only makes both rotating speeds separate regulation, but can make both velocity ratios be in optimum level, and guarantees the best loose-stratification state of stream film, separation index is improved.

- What the sorting card of this suspension cone shaking table produced is that a conical surface is sprawled the streaming film and the streaming film is by thick attenuation gradually in its flow process, and flow velocity also reduces thereupon gradually, very favorable to the recovery of fine fraction mineral.

- The card bracing frame flexibly connects through a steel wire rope and rotation system, being delivered on the sorting face of energy maximum that the whirling vibration system vibration produces, and the efficiency of separation is high, and energy consumption is low.

- The sorting conical surface is assembled to form by polylith separate unit face, which helps equipment enlarge transportation, and installation.

- The sorting conical surface adopts the glass-reinforced plastic material processing and manufacturing, life-span length, lightweight, and flatness height.

The suspension cone shaking table is suitable for separating sludge with particle sizes ranging from 10 microns to 100 microns. And the cone slope of the bed is 3°~10°. The advantages of this suspension cone shaker include high sorting efficiency, large processing capacity, and low energy consumption, but it has high operating technology requirements and requires relatively precise control and adjustment.

Advantages

Suspension Cone Shaking Table Advantages

The suspension cone shaking table offers significant advantages for fine-grained mineral separation, combining environmental benefits with operational efficiency. As a gravity-based separation system, it requires no chemical additives, eliminating environmental contamination while consuming minimal energy (approximately 0.7kW with frequency converter control). The equipment dramatically outperforms traditional vibrating machines, processing over 10 times more material while handling unclassified particles as fine as -100μm (150 mesh) with consistent performance. Its low infrastructure requirements stem from minimal vibration and straightforward installation, reducing capital investment. Particularly effective for fine mineral separation across varied specific gravities, this versatile solution delivers high-capacity processing within a compact, eco-friendly design suitable for diverse mineral applications.

- High recovery rate – The recovery rate of fine-grained minerals (such as -200 mesh gold and tungsten) is >90%, far exceeding that of ordinary shakers.

- Energy-saving and high-efficiency – The power consumption is 30~50% lower than that of traditional equipment, and the processing capacity is increased by 2~3 times.

- Intelligent adjustment – The adjustable parameters include: vibration frequency (0~50Hz), cone inclination (0°~15°), and water volume/feed concentration.

- Environmental protection and low consumption – No chemical agents, water can be recycled.

Structures & Working Principle

Suspension Cone Shaking Table Structure

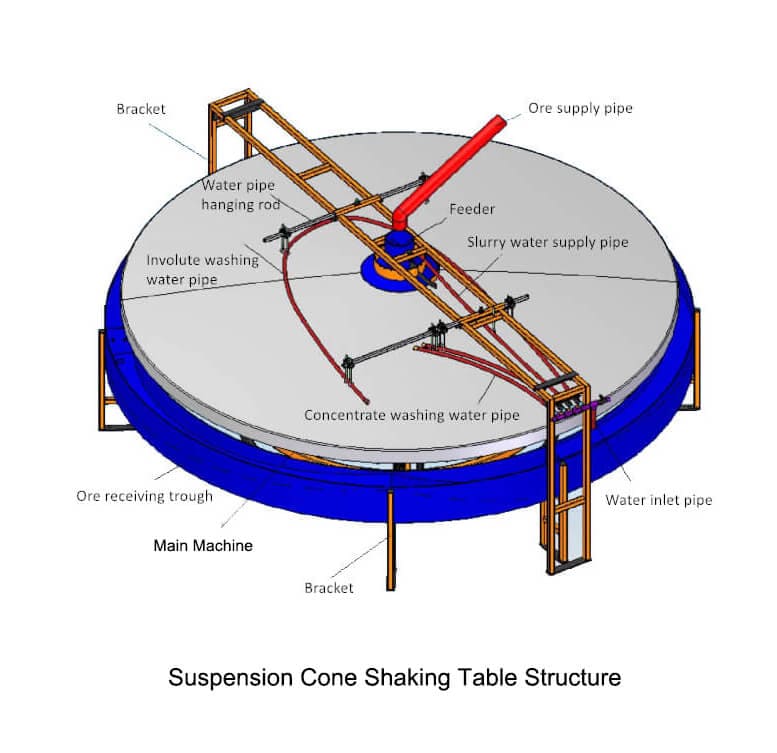

The structure of the suspension cone shaking table includes the following key parts:

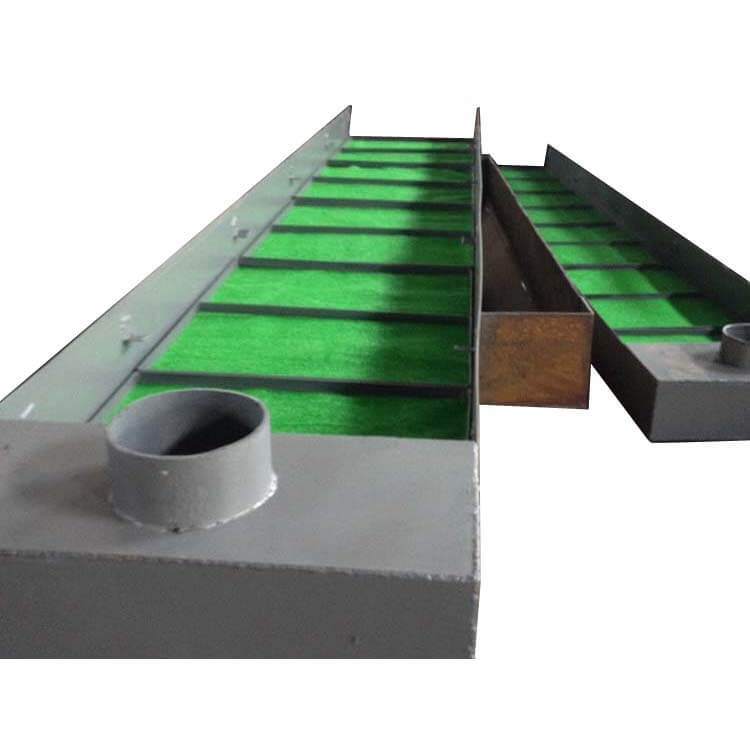

- Bed: With vibration and rotation mechanism, the slope of the cone surface is 3°~10°, which is conducive to the sorting of fine-grained minerals.

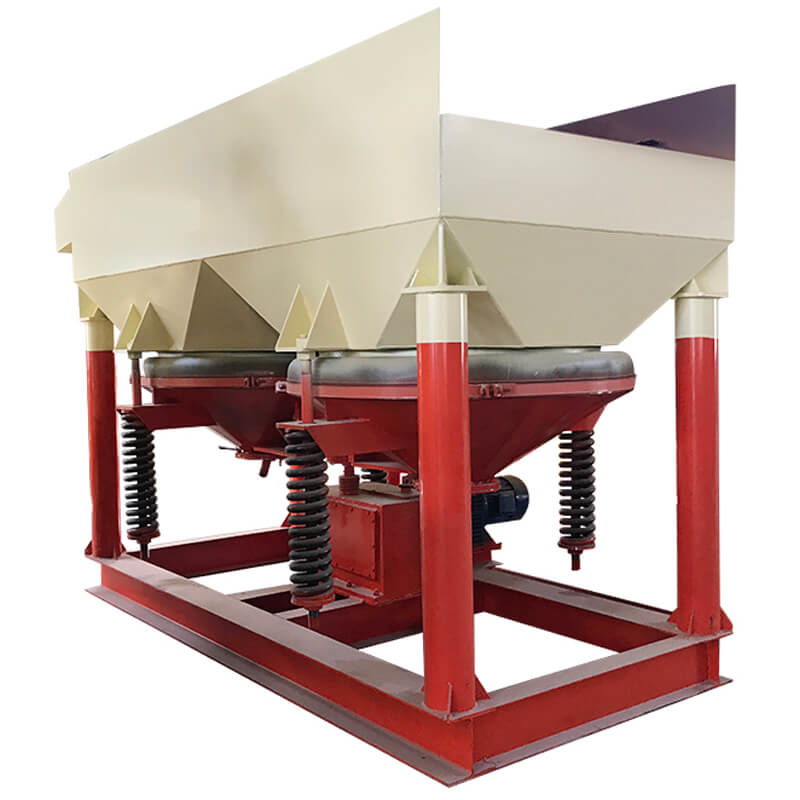

- Lower bracket: Equipped with the motor roller, installed on the circular track, and fixed with suspension columns.

- Upper bracket: Suspended on the lower bracket by hanging hooks and hanging ropes, equipped with an eccentric pendulum mechanism connected to the motor.

- Vibration and rotation mechanism: Reasonable design, can achieve effective sorting of fine-grained minerals, and has the advantages of low water consumption, small footprint, and long equipment life.

- Motion mechanism: The design makes the equipment easy to manufacture, transport, and install on a large scale, and is suitable for sorting sludge with a particle size of 100 microns to 10 microns.

The suspended vibration cone shaker effectively improves the efficiency and accuracy of mineral sorting through its unique structure and movement mode and is particularly suitable for processing fine-grained minerals.

Suspension Cone Shaking Table Working Principle

The suspension cone shaking table is a new type of fine particle gravity separation equipment developed based on the Baigno shear loosening theory and the film concentrator principle.

When the evenly stirred slurry enters the primary selection area of the disc from the feeder at the center of the sorting cone, the slurry flow spreads out in a fan shape and flows to the periphery. During its flow, the film gradually becomes thinner from thick, and the flow rate gradually decreases. The ore particles are moderately loosened and layered on the disc under the action of their gravity and the shear repulsion generated by the gyratory vibration. The rotation of the conical disc brings minerals of different densities into the tailings trough, the intermediate ore trough, and the concentrate trough in turn.

The distribution of the ore layers on the sorting cone conforms to the structure of the laminar slurry film. The top surface layer is mainly light minerals with small particle sizes and low density. The pulsation speed of this layer is not large, and its value roughly determines the lower limit of particle size recovery. Most of the suspended ore particles are discharged into the tailings trough in the roughing area. The rheological layer in the middle is mainly composed of heavy minerals with small particle sizes and high density, and light minerals with large particle sizes and low density. This layer has the largest thickness and the strongest Baigno force. Since the particle group in this layer is highly dense and there is no large vertical medium flow velocity interference, the stratification can be carried out close to static conditions, so the rheological layer is a more effective area for stratification by density. As the equipment rotates, some minerals are discharged into the middle ore tank under the sorting effect of the washing water in the middle ore area. The bottom sedimentary layer is mainly composed of heavy minerals with high density. The distribution law of particle size is fine near the top of the cone, and the particle size becomes coarser towards the discharge end. The fine and micro-fine heavy minerals in this layer are easy to adhere to the sorting surface tightly and are not easily carried away by the slurry flow. Therefore, when the equipment runs to the concentrated area, the concentrate can be obtained by the action of the washing water.

Technical Parameters

| Feeding Size | 0.010-0.074 mm |

| Cone Diameter | 4200 mm |

| 4400mm | |

| Feeding Concentration | 15%-25% |

| Capacity | 8-15 ton per day |

| Enrichment Ratio | 6-30 times |

| Overall Dimension | L4800*W4800*H2300 mm |

| L5000*W5000*H2300 mm | |

| Power | 1.5 kw |

| Weight | 1.6 ton |

| 1.87 ton |