Square Swing Vibration Screen

Screening Size: 3-6 m2

Motor Power: 3-7.5 kW

Screen Layer: 1-5 available

Screen Box Stroke: 25-60 mm

Applications: It is used in mineral processing, building materials, chemical industries, food, metallurgy, abrasives, and other industries.

Square Swing Vibration Screen Overview

The square swing vibrating screen is a commonly used screening equipment with a simple structure and easy-to-understand principle. It uses vibration force to screen materials in the screen box and has the characteristics of high efficiency and large processing capacity. It has broad application prospects in mining, metallurgy, the chemical industry, and other industries.

Square Swing Screen Features

- Our square swing vibration screen has efficient screening capabilities. The equipment uses a swing screen for screening, which can quickly and effectively separate chromium ore into particles of different sizes. Its screening efficiency is high, and it can greatly improve production efficiency.

- Our square swing screen has stable working performance. The equipment is made of high-quality materials, has a solid and stable structure, can maintain good operating conditions during long work periods, is not prone to failure, and has a long service life.

- Our square swing screen has a flexible adjustment function. Users can adjust the swing frequency and amplitude of the screening machine as needed to achieve screening requirements for different granular materials, which have strong applicability and flexibility.

- Our square swing screen also has an automatic cleaning function. The equipment is equipped with a cleaning device that can regularly clean impurities and blockages on the screen to ensure the screening effect and the regular operation of the equipment.

The square swing vibrating screen is ideal screening equipment and is widely used in mining, metallurgy, the chemical industry, and other industries. It has the characteristics of high efficiency, stability, flexibility, and automatic cleaning.

Square Swing Screen Details

- Fully enclosed structure

The square swing screen has a fully enclosed structure, which prevents dust from flying. It uses a biased balance to make the screen machine less vibrating and noisy. Comply with environmental protection requirements.

- Screening of various materials

The square swing screen combines three motion modes: circumferential, circular, and linear. It has a good screening effect and is suitable for screening various materials.

- Long service life

The square swing screen is equipped with an automatic tensioning and automatic cleaning screen installation system, which enables high screen utilization, long service life, and a simple and fast screen-changing structure.

Advantages

Square Swing Vibration Screen Advantages

- High screening efficiency

The square swing screen adopts a multi-layer structure, which is especially suitable for materials that require multi-layer classification. This structure can effectively improve screening efficiency. It also has an automatic screen cleaning device to avoid material clogging.

- High screening accuracy

The square swing screen uses vibration force to transfer to the screen surface for screening, which can quickly stratify the materials on the screen surface, thereby improving screening accuracy. In addition, the vibration frequency and amplitude of the square swing screen can be adjusted as needed to adapt to the screening requirements of different materials.

- Simple structure and easy maintenance

The structure of the square swing screen is relatively simple and easy to maintain. At the same time, the screen mesh of the square swing screen adopts a pull-tension type and can be easily replaced.

- Wide range of application

The square swing screen is suitable for screening various powdery and granular materials, including grain, chemical raw materials, pharmaceutical raw materials, food additives, etc. At the same time, the square swing screen can also be customized as needed to meet the screening requirements of different industries.

Structures & Working Principle

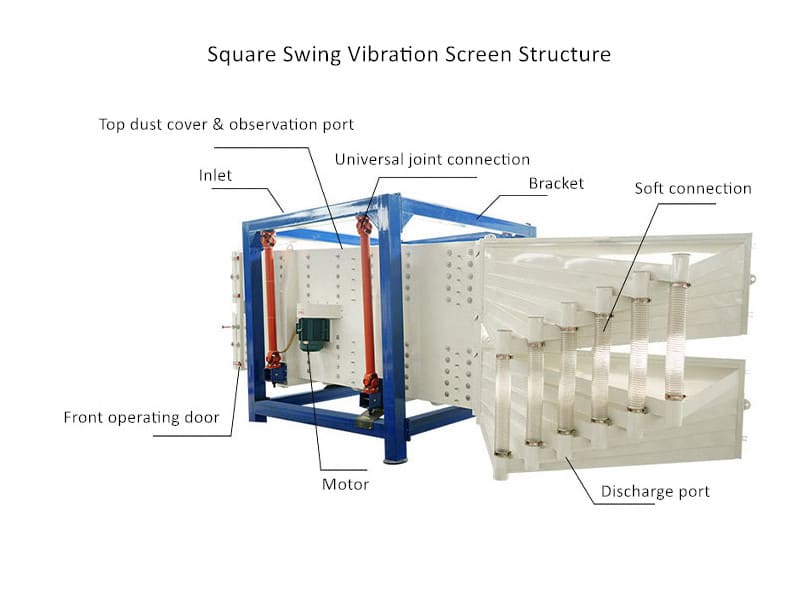

Square Swing Vibration Screen Structure

The square swing screen is mainly composed of a screen box, vibrator, spring, etc. The screen box is a square container with a screen inside. The vibration force generated by the vibrator is transmitted to the screen box through the excitation motor, causing it to produce a rocking motion. The spring plays a buffering and supporting role to ensure the stability of the screen box.

Square Swing Vibration Screen Working Principle

The working principle of the square swing screen is to screen materials in the screen box through vibration force. When the vibration force acts on the screen box, the materials will move relative to each other on the screen. The screen will block materials with larger particles and cannot pass through. In comparison, materials with smaller particles can pass through the screen, achieving the screening purpose.

Technical Parameters

| Model | Screening Size (m2) | Layer | Lateral Slope | Motor Power (kW) | Number of Revolutions (r/min) | Screen Box Stroke (mm) |

| FYBS1030 | 3 | 1-5 | 5-8° | 3 | 180-260 | 25-60 |

| FYBS1036 | 3.6 | 1-5 | 5-8° | 3 | 180-260 | 25-60 |

| FYBS1230 | 3.6 | 1-5 | 5-8° | 4 | 180-260 | 25-60 |

| FYBS1236 | 4.32 | 1-5 | 5-8° | 4 | 180-260 | 25-60 |

| FYBS1530 | 4.5 | 1-5 | 5-8° | 5.5 | 180-260 | 25-60 |

| FYBS1536 | 5.4 | 1-5 | 5-8° | 5.5 | 180-260 | 25-60 |

| FYBS1830 | 5.4 | 1-5 | 5-8° | 7.5 | 180-260 | 25-60 |

| FYBS1836 | 6.48 | 1-5 | 5-8° | 7.5 | 180-260 | 25-60 |

| FYBS2030 | 6 | 1-5 | 5-8° | 7.5 | 180-260 | 25-60 |