Spiral Sand Washing Machine With Trommel Screen

Capacity: 1-160 TPH

Applicable Materials: Suitable for sand, placer gold, coal, coke, lime, mountain sand, weathered sand, and other materials.

Application Area: It is used for washing materials in sand and gravel plants, mines, building materials, transportation, water conservancy, and hydropower, mixing stations, and other industries.

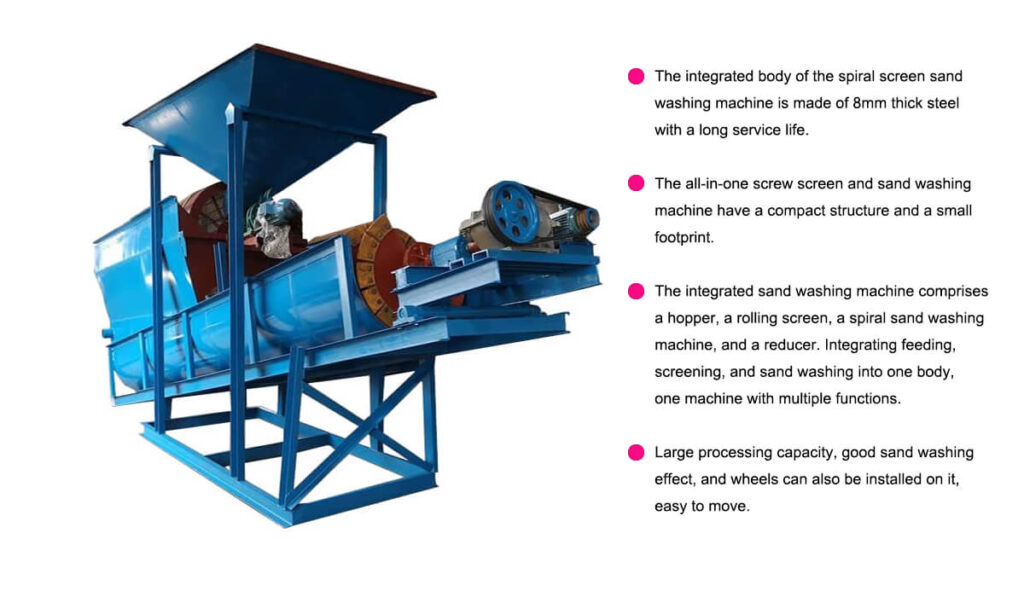

Spiral Sand Washing & Screening Integrated Machine Overview

The spiral sand washing machine with a trommel screen is a type of sand washing machine used for separating and cleaning sand and aggregates. This integrated equipment combines the needs of sand washing equipment and realizes that a single machine can perform the functions of feeding, screening, and sand washing. This combination of equipment is commonly used in construction, mining, and other industries where cleaning and classifying granular materials like sand is necessary.

Features

- The integrated body of the spiral screen sand washing machine is 8mm thick steel with a long service life.

- The all-in-one screw screen and sand washing machine have a compact structure and a small footprint.

- The integrated sand washing machine comprises a hopper, a rolling screen, a spiral sand washing machine, and a reducer. Integrating feeding, screening, and sand washing into one body, one machine with multiple functions.

- Its large processing capacity, good sand-washing effect, and wheels can also be installed on it, making it easy to move.

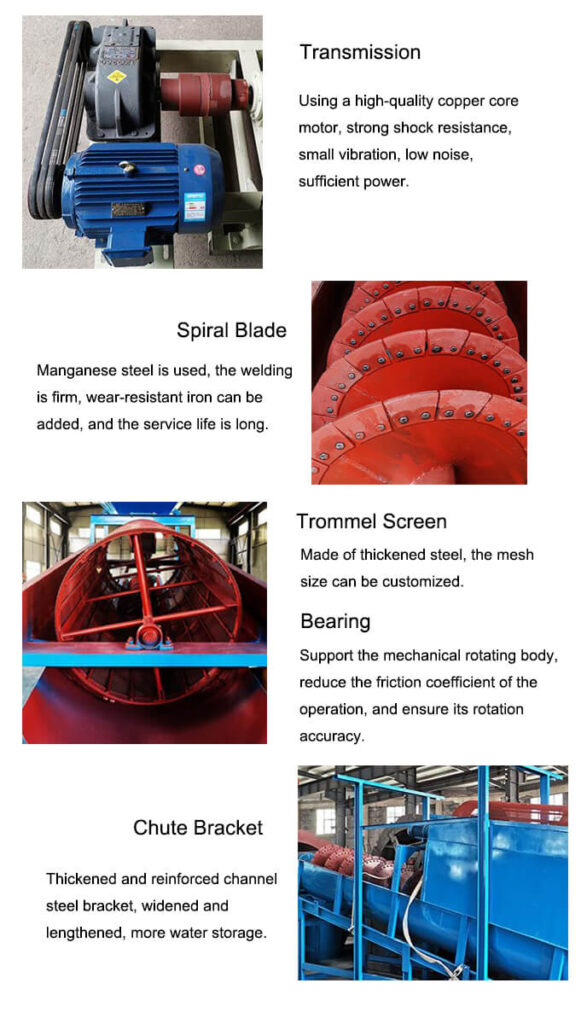

Spiral Sand Washing And Screening Integrated Machine Details

- Transmission

Using a high-quality copper core motor, strong shock resistance, small vibration, low noise, and sufficient power. - Spiral blade

Manganese steel is used, the welding is firm, wear-resistant iron can be added, and the service life is long. - Trommel screen

Made of thickened steel, the mesh size can be customized. - Chute bracket

Thickened and reinforced channel steel bracket, widened and lengthened, more water storage. - Bearing

Support the mechanical rotating body, reduce the friction coefficient of the operation, and ensure its rotation accuracy.

Trommel Screen And Spiral Washer Plant Process

Feed Hopper: The process begins by introducing raw material, usually sand and water, into a feed hopper.

Trommel Screen: The trommel screen is a cylindrical drum-like structure with perforated holes. It rotates to separate the larger-sized materials from the smaller ones. As the drum rotates, the smaller particles (sand, dirt, and other fine materials) fall through the holes in the trommel screen, while larger materials are retained and conveyed along the length of the drum.

Spiral Sand Washer: The retained larger materials are then transported along the length of the trommel to the discharge end. At this point, the spiral sand washing machine comes into play. It consists of a spiral screw-shaped conveyor that lifts and agitates the retained materials, effectively cleaning and washing the particles. Water is usually added to aid in the washing process, helping to remove impurities, clay, and contaminants from the material.

Discharge Chute: Cleaned and washed materials are discharged through a chute or conveyor for further processing or use.

Advantages

Spiral Screening Washing Machine Advantages

- Efficient Cleaning: Combining a Trommel screen and spiral sand washer allows efficient cleaning and separation of materials based on size and weight.

- Versatility: This setup can handle a wide range of materials, from sand to aggregates, and can be adjusted to accommodate different sizes of particles.

- Minimal Water Usage: The water used in the process is typically recycled within the system, reducing water consumption compared to traditional washing methods.

- Automation: Depending on the setup, the process can be automated to a certain extent, improving operational efficiency.

- Space Saving: Combining a Trommel screen and spiral sand washer saves space compared to using two separate machines.

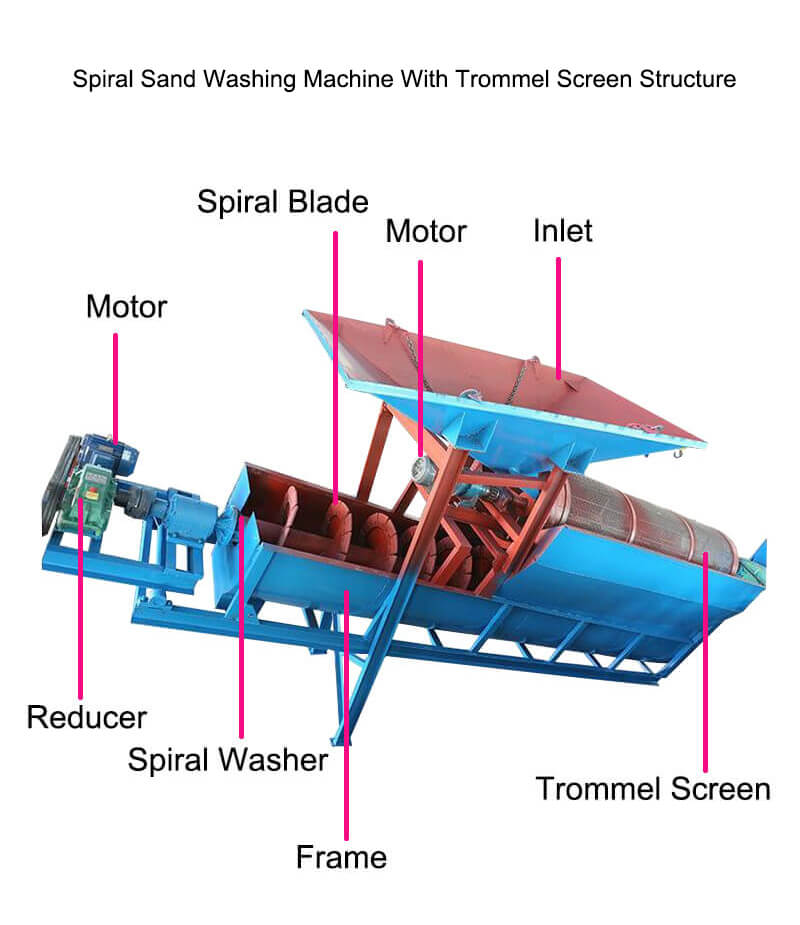

Structures & Working Principle

Spiral Sand Washing & Screening Integrated Machine Structure

The spiral screen washing machine comprises a hopper, a drum screen, a spiral sand washing machine, and a reducer. The drum screen is connected to the top of the spiral sand washing machine. The whole equipment is vertical, and the integrated and vertical structure naturally reduces the occupation land area. The spiral screen sand washing machine can also have wheels for easy movement.

Spiral Screening Washing Machine Working Principle

When the all-in-one sand screening and washing machine is working, the processed materials first enter the bucket drum sand washing device. After being screened in the drum device, two kinds of materials with different particle sizes are formed. The lower material enters the water storage tank in the middle section. After being cleaned and screened by the spiral blade, the qualified material enters the back-end dehydration device for dehydration treatment. In the water storage tank, the high-pressure water pump is pumped into the separation and recovery device after centrifugal concentration. After that, the feasible material plate is sent to the dehydration device for dehydration.

Technical Parameters

| Model | JXSC-50 | JXSC-75 | JXSC-100 | JXSC-120 | JXSC-150 | JXSC-200 | |

| Hopper Size W*L (mm) | 2400*1200 | 2600*1400 | 3400*1400 | ||||

| Trommel Screen | Size W*L (mm) | 800*1900 | 900*2800 | 1000*3600 | |||

| Motor | 2.2kW Rotating speed: 18-19r | 3kW Rotating speed: 18-19r | 3kW Rotating speed: 18-19r | ||||

| Spiral Washing Machine | Size W*L (mm) | 500*4500 | 750*5500 | 1000*6500 | |||

| Motor | 3kW Rotating speed: 11r | 3kW Rotating speed: 11r | 4kW Rotating speed: 11r | ||||

| Spiral Pitch(mm) | 350 | 400 | 450 | ||||

| Reducer | 200 | 250 | 350 | ||||

| Capacity (T/H) | 1-20 | 40-55 | 60-75 | 80-100 | 100-130 | 130-160 | |

| Over Size L*W*H (mm) | 5500*1200*2600 | 6500*1200*2500 | 8000*1400*2600 | ||||

| Weight(kg) | 2800 | 3900 | 4200 | 6900 | 8800 | 19000 | |