Slurry Pump

Capacity: 4.5-3300 m3/h

Head: 5-130 m

Speed: 300-2900 rpm

Lift Head: 4-128.7 m

Application: Mineral processing, metallurgy, coal, power, petroleum, chemical industry, sand excavation, urban sewage, environmental protection, and other industries.

Slurry Pump Overview

The slurry pump is a large-scale centrifugal pump, which is mainly used to transport the medium containing abrasive solid particles. It’s widely used for slurry transportation in metallurgical concentrators, hydraulic ash removal in thermal power plants, coal slurry and heavy medium transportation in coal washing plants, slurry lifting in sand washing plants, river dredging, etc. In the alumina production process, the slurry pump mainly transports raw material slurry with high temperature, strong abrasion resistance, and large solid particle content, so it is also called a slag-slurry pump. The slurry pump is indispensable universal equipment in the mining, chemical, coal, and metal smelting industries.

Types of Slurry Pumps

Suction inlet: Single suction slurry pump and double suction slurry pump.

Position of pump shaft and horizontal plane of slurry pump: horizontal slurry pump and vertical slurry pump. (Horizontal slurry pumps: heavy duty, HH, ZJ, ZGB and other series. Vertical slurry pumps: AF foam pumps, SP submerged slurry pumps, SPR submerged rubber lined slurry pumps, ZJL submerged slurry pumps and other series.)

Number of impellers: Single stage impeller slurry pump and multistage impeller slurry pump.

The structure of pump shell: Single shell slurry pump and double shell slurry pump.

● ZJ Serial Slurry Pump

Material: High chromium alloy wear-resistant material.

Application: It is suitable for electric power, metallurgy, coal, building materials, the chemical industry, and other industrial industries. It is mainly used to treat corrosive slurry containing solid particles. Such as coal ash water transportation in coal preparation and washing plants, ore beneficiation in mining plants, desulfurization of limestone slurry in power plants, and coal preparation The factory transports coal slurry, etc.

ZJ series slurry pump is a single-stage, single-suction, centrifugal slurry pump. It has innovations in water conservancy design and structural design. The overflow parts are made of self-developed high-chromium wear-resistant alloy with high efficiency. , energy saving, long service life, light weight, reasonable structure, reliable operation, low vibration, low noise, convenient maintenance and other significant features.

● Heavy Duty Slurry Pump

Material: High chromium alloy wear-resistant material

Application: Widely used in metallurgy, mining, coal, chemical industry, power plant, sand pumping, environmental protection, municipal engineering, and other industries.

The heavy duty slurry pump is a cantilever and centrifugal pump. The horizontal and vertical axial split double pump shell structure is adopted, and the lining is hard alloy, which has good wear resistance, corrosion resistance, and high reliability. The product has a reasonable structure, reliable operation, and long service life. Especially suitable for medium and high concentration and strong abrasion conditions.

● ZGB Serial Slurry Pump - Heavy Slurry Pump

Material: High chromium alloy wear-resistant material.

Application: ZGB slurry pump is widely used in electric power, metallurgy, mining, coal, building materials, chemical, and other industrial sectors to transport abrasive or corrosive slurry, especially power plant ash and slag transport. After special treatment, it can also be used for seawater ash removal and electrochemical corrosion of seawater and salt spray. Within the allowable pressure range, it can be used in multi-stage series, and its maximum allowable working pressure is 3.6Mpa.

ZGB series is a cantilever, horizontal double-shell axial suction centrifugal heavy-abrasion high-lift slurry pump. It has the advantages of large flow, high lift, low wear rate, high efficiency, good anti-clogging performance, superior cavitation performance, reliable operation, and convenient maintenance. The overcurrent parts are made of special materials, with good wear resistance and corrosion resistance; the bracket part uses thin oil-lubricated metric bearings, and the lubrication and cooling system is reasonably set to ensure that the bearings operate at low temperatures.

ZGB slurry pump adopts a combined seal or mechanical seal with impeller and packing to ensure no leakage of slurry.

● Ceramic Slurry Pump - Silicon Carbide Slurry Pump

Material: Ceramic

Application: It is suitable for cyclone feed abrasive pumps, concentrates conveying, tailings conveying, and other working conditions in thermal power plants, coal mines, and metal concentrators.

The ceramic slurry pump is a centrifugal slurry pump with an overflow material made of ceramic, and the main material of the ceramic is silicon carbide. It can resist all acid and alkali corrosion and has excellent wear resistance, but if it cannot be achieved in technology, the ceramic flow parts are easily broken when transporting large particles and impact media.

The biggest feature of ceramic slurry pumps is both wear resistance and corrosion resistance, and the wear resistance and corrosion resistance are much higher than alloy pumps and rubber pumps.

Besides the above-referred slurry pumps, we also manufacture HH, ZJL, SP, and G serials slurry pumps. Please click here to ask our engineer or seller for the product details.

Advantages

Slurry Pumps Advantages

- Heavy Duty, High Head(HH), and Middle Duty(M) slurry pumps: Material selection of flow passage parts can be a wear-resistant metal material or wear-resistant rubber material.

- ZJ serial slurry pumps: The slurry pump was developed in China. It has a simple structure and belongs to the medium and light type slurry pump.

- ZGB series slurry pump: Heavy slurry pump, can be used in series.

- SP and ZJL serial slurry pumps: When they work, some pump bodies can be directly immersed in the liquid. Most of them are used under coal washing conditions and power plant conditions.

The slurry pump can be widely used in mining, electric power, metallurgy, coal, environmental protection, and other industries to transport slurry containing abrasive solid particles.

- Mining industry (concentrator)

The solid slurry of the mud particles in the mine cannot be removed manually, and the slurry pump can easily remove it. Due to the bad working environment in the mine, the service life of the slurry pump is greatly affected. - Power industry (power plant)

The power plant is mainly hydropower and thermal power. The thermal power plant generates a lot of ash mixed with scale through coal-fired power generation, which requires a slurry pump to clean it up. Therefore, the thermal power plant is also called a slurry pump. - Coal washing industry

Since the coal blocks are relatively large and mostly solid, it is very easy to block the slurry pump. The coal-washing industry has very high requirements for the slurry pump, so it is necessary to select a slurry pump with high flow and high throughput. - Seawater sand separation

The slurry pumps in the seawater sand separation industry are all used to transport some slurry, which is the most suitable choice for slurry pumps. - Dredging of river channel

The slurry pump is also called the dredging pump when dredging the river and dredging the river. Due to the characteristics of the slurry pump, the slurry pump is most commonly used when dredging the river.

Structures & Working Principle

Slurry Pumps Structures

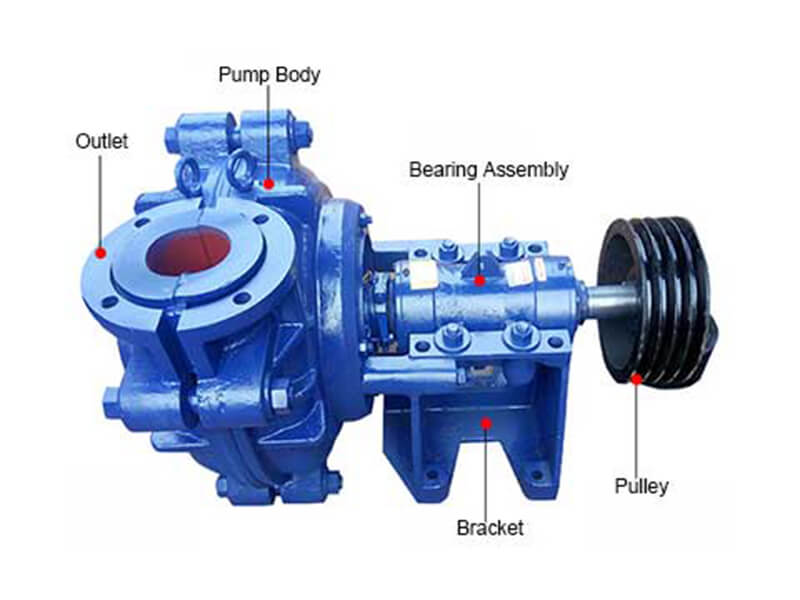

The slurry pump is usually composed of a pump head, bracket, shaft seal, bearing assembly, etc.,

- Pump Head

- Double-layer pump housing (double-layer metal structure inside and outside).

- The double pump housing structure is a vertical split type, and the water outlet can be installed and used in 8 different positions according to 45-degree intervals.

- The combination of power seal, packing seal or mechanical seal is adopted to prevent the leakage of shaft seal.

- A labyrinth clearance seal is set between the impeller and the rear guard plate, which greatly reduces the leakage of slurry to the stuffing box and effectively ensures the reliability of the seal.

- The impeller is equipped with back blades to discharge the backflow slurry in time, to improve the volume ratio, reduce backflow and erosion, and improve the service life of the flow parts.

- The removal ring is convenient for maintenance and disassembly.

- Bracket Structure

- The bracket structure is a horizontal split type, which extends the service life of the bearing.

- The hydraulic design and structural design are optimized.

- Rational distribution of radial force and axial force.

- Correct selection of bearing form, model, cooling and lubrication methods, etc., thus achieving the requirements of low heating and long life of the bearing.

- Shaft Seal

The shaft sealing device plays a sealing role between the pump body and the pump shaft. It can prevent air from entering the pump and a large amount of water from leaking out of the pump.

- Bearing Assembly

The bearing assembly of the slurry pump adopts a cylinder structure, which is convenient for adjusting the clearance between the impeller and front guard board and can be removed as a whole during maintenance. The bearing is lubricated with grease.

Slurry Pumps Working Principle

The slurry pump refers to a kind of machinery that increases the energy of solid-liquid mixed medium by the centrifugal force (the rotation of the impeller of the pump), and converts the electric energy into the kinetic energy and potential energy of the medium. Under the action of centrifugal force, the liquid is thrown from the center of the impeller to the outer edge and gets energy, leaving the outer edge of the impeller at high speed and entering the volute pump shell. In the volute pump case, the liquid decelerates due to the gradual expansion of the flow channel, then converts part of the kinetic energy into static energy, and finally flows into the discharge pipe at a higher pressure and is sent to the required place. When the liquid flows from the impeller center to the outer edge, a certain vacuum is formed in the impeller center. Since the pressure above the liquid level of the storage tank is greater than the pressure at the pump inlet, the liquid is continuously pressed into the impeller.

Technical Parameters

ZJ Slurry Pump Parameters

| Model | Max. Power(Kw) | Capacity (m3/h) | Head(m) | Speed (r/min) |

| 40ZJ-I-A17 | 7.5 | 4.5-23.4 | 9.1-44.6 | 1400-2900 |

| 50ZJ-I-A46 | 55 | 23-94 | 17.9-85.8 | 700-1480 |

| 65ZJ-I-A30 | 15 | 23-79 | 7.4-34.8 | 700-1460 |

| 80ZJ-I-A36 | 45 | 46-190 | 9.6-51.4 | 700-1480 |

| 100ZJ-I-B42 | 90 | 83-365 | 12.7-66.8 | 700-1480 |

| 150ZJ-I-C42 | 132 | 142-550 | 12.1-62.8 | 700-1480 |

| 200ZJ-I-A65 | 250 | 235-950 | 16.4-72 | 490-980 |

| 250ZJ-I-A85 | 800 | 376-1504 | 30.1-128.7 | 490-980 |

| 300ZJ-I-A100 | 450 | 464-1826 | 15.3-65.2 | 300-590 |

| 350ZJ-I-C104 | 560 | 1335-3300 | 36.6-66.9 | 490-590 |

AH Slurry Pump(R) Parameters

| Model | Power(Kw) | Capacity (m3/h) | Head(m) | Impeller Ⴔ(mm) |

| 1.5/1B-A H | 15 | 12.6 ~ 28.8 | 6 ~ 68 | 152 |

| 10.8 ~25.2 | 7 ~ 52 | 330 | ||

| 2/1.5B-A H | 15 | 32.4 ~ 72 | 6 ~ 58 | 184 |

| 25.2 ~ 54 | 5.5 ~ 41 | 178 | ||

| 3/2C-A H | 30 | 39.6 ~ 86.4 | 12 ~ 64 | 214 |

| 36 ~ 75.6 | 13 ~ 39 | 213 | ||

| 4/3C-A H | 30 | 86.4 ~ 198 | 9 ~ 52 | 245 |

| 79.2 ~ 180 | 5 ~ 34.5 | 245 | ||

| 4/3D-A H | 60 | 97.2 ~ 198 | 9 ~ 53 | 245 |

| 79.2 ~ 180 | 5 ~ 34.5 | 245 | ||

| 6/4D-A H | 60 | 162 ~ 360 | 12 ~ 56 | 365 |

| 144 ~ 324 | 12 ~ 45 | 371 | ||

| 6/4E-A H | 120 | 162 ~ 360 | 12 ~ 56 | 365 |

| 144 ~ 324 | 12 ~ 45 | 371 | ||

| 8/6E-A H | 120 | 360 ~ 828 | 10 ~ 61 | 536 |

| 510 | ||||

| 8/6R-A H | 300 | 324 ~ 720 | 7 ~ 49 | 536 |

| 510 |

Submerged Slurry Pump Parameters

| Model | Match Power (KW) | Flow Capacity (m3/h) | Lift H(m) | Speed (r/min) | Impeller Diameter Ⴔ(mm) |

| 40PV-SP | 1.1-15 | 7.2-29 | 4-28.5 | 1000-2200 | 188 |

| 65QV-SP | 3-30 | 18-113 | 5-31.5 | 700-1500 | 280 |

| 100RV-SP | 5.5-75 | 40-289 | 5-36 | 500-1200 | 370 |

| 150SV-SP | 11-110 | 108-576 | 8.5-40 | 500-1000 | 450 |

| 200SV-SP | 15-110 | 180-890 | 6.5-37 | 400-850 | 520 |

| 250TV-SP | 18.5-200 | 261-1089 | 7-33.5 | 400-750 | 575 |

| 300TV-SP | 22-200 | 288-1267 | 6-33 | 350-700 | 610 |