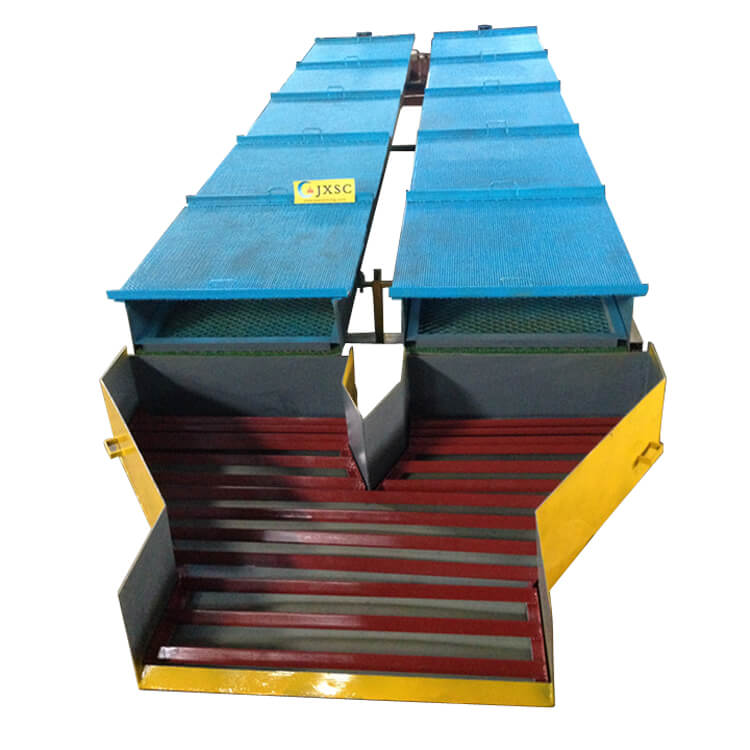

Sluice Box

Capacity: 0-25 TPH

Feeding Size: 20 mm

Process Material: Main in alluvial gold, tin

Sluice Box Overview

Sluice boxes are often used in the recovery of black sands, gold, and other minerals from placer deposits during placer mining operations. They may be small-scale, as used in prospecting, or much larger, as in commercial operations, where the material is sometimes screened using a trommel, screening plant, or sieve.

The sluice box is often called the gold sluice box. It with mat is a kind of mineral gravity separation equipment, mainly used in the alluvial gold wash plant, gold dredger, and open-pit gold mining, and definitely an important gold panning equipment. High recovery rate, mature technology, wide application, economic and environmental protection.

Gold Sluice Box Types

There are stationary sluice boxes, portable sluice boxes, and vibrating gold sluice boxes.

According to the capacity, divided into large scale sluice and small sluice box. The former is used in the open-pit mining plant, ore granularity is 50-100mm; the mini gold sluice box on gold dredger, mobile gold mining plants, and the granularity is less than 20mm.

Advantages

Sluice Box Advantages

- Low price, no electric power need, lightweight, easy installation.

- Adjustable combined with grizzly feeder, hopper, trommel scrubber, vibrating screen, centrifugal concentrator;

- Install the gold carpet/mat to catch the fine and coarse gold.

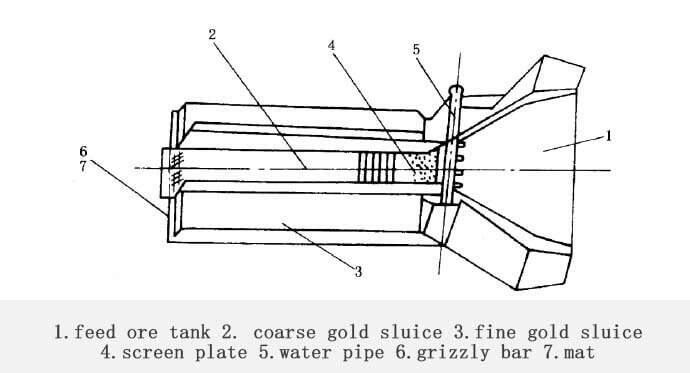

Structures & Working Principle

Gold Sluice Box Structure

The main parts of a sluice box are grizzly bar, sluice, mat, frame, water pipe, etc.,

Gold Sluice Box Working Principle

Placer gold mining refers to separating gold from alluvial gold deposits. Under the combined action of water flow force, gravity (or centrifugal force) and friction between ore particles and trough bottom, ore particles with different specific gravity are loosely stratified and separated. Heavy density settles in the bottom of the trough into concentrate, the small density proportion flows out, that is tailings.

Technical Parameters

| Model | Length (mm) | Width (mm) | Capacity (t/h) |

| JXSC-4000X1000 | 4000 | 1000 | 10-15 |

| JXSC-6000X1000 | 6000 | 1000 | 20-25 |