SF Flotation Cell/Machine

Capacity: 0.2~20 m³/min

SF flotation cell is a mechanical agitation type with slurry suction and air suction.

SF Flotation Cell/Machine Overview

Flotation machines constitute the basic equipment for useful minerals recovery from non-ferrous ores and other raw materials by flotation. They can operate also as individual flotation cells.

Flotation Cells (Froth Flotation) were developed to separate and recover high-value Sulphide ores from low-grade ore bodies. The Flotation Cell is aerated to produce bubbles and agitated to keep the solids particles in suspension in the pulp. A flotation cell is an appliance in which froth flotation of ores is performed. It has provision for receiving conditioned pulp, aerating this pulp, and for separate discharge of the resulting mineralized froth and impoverished tailings.

Flotation Cells/Machines Types

- Agitating flotation machine

- Self-priming flotation machine

- Aeration flotation machine

- Flotation column machine

Flotation Cells/Machines For Sale

Our froth flotation separation is sold all around the world and is popular with clients. The models of our flotation cells are main including SF, XJK, JJF, XCF, KYF flotation cells.

Advantages

SF Flotation Cell/Machine Advantages

- It can be combined with the JJF flotation cell in a combined flotation unit as a sucking tank for every operation.

- Mechanical agitation with self-air-inflation and self-priming pulp.

- Upper and lower recirculation in the well-defined path, sanding of coarse particles is minimized, it is advantageous for coarse ore flotation.

- The gap between the impeller and cover plate is large with a large air inflation amount. Less energy consumption.

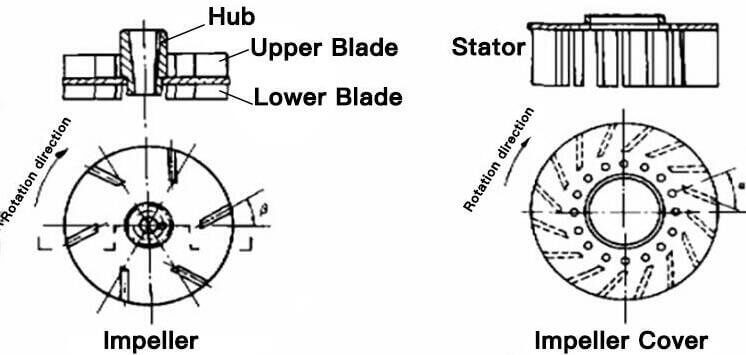

- Backward double-sided blades are equipped on the impeller, which realizes the double loop of slurry in the tank.

- Lower speed of the rotor to extend wear life.

- Forward leaning tank with small blind angle. The foam moves fast. Beveled tank design, stable operation, and proven metallurgical design.

Structures & Working Principle

SF Flotation Cell/Machine Structure

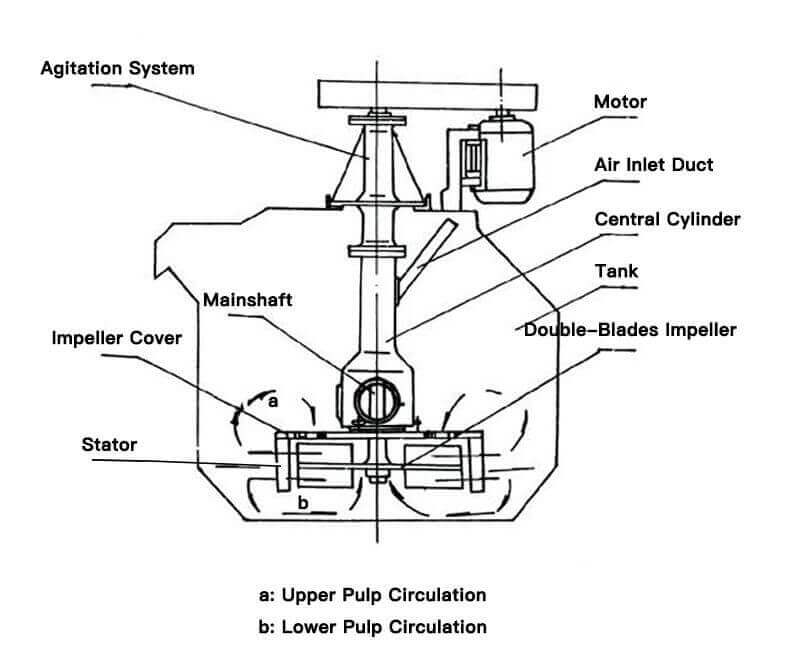

The structure of the SF flotation cell is mainly composed of the tank, impeller, motor, scraper and transmission device, etc.

SF Flotation Cell/Machine Working Principle

When the rotor is rotating, an internal vacuum is created both in the upper and lower blade zone. Ambient air is drawn through an air intake pipe and standpipe by the action of the upper blade, the bubbles are then micronized and make the minerals easier to stick on the bubbles. Mineral particles are collected by air bubbles forming aggregates in the contact zone, and Mineralized Bubbles aggregates rise by buoyancy towards the froth zone. The pulp from the upper tank zone is recirculated by the upper blade, while the lower blade is designed to recirculate slurry from the bottom of the tank to minimize the sanding of coarse particles.

Technical Parameters

| Model | Volume(m3) | Cell Size(mm) | Impeller Dia.(mm) | Impeller Speed(r/min) | Capacity(m3/min) | Power(kW) | Singe cell weight(kg) |

| SF-0.37 | 0.37 | 700×700×750 | 296 | 386 | 0.2-0.4 | 1.5/0.55 | 468 |

| SF-0.7 | 0.7 | 820×900×950 | 350 | 400 | 0.3-0.9 | 3/1.1 | 805 |

| SF-1.2 | 1.2 | 1100×1100×1100 | 450 | 312 | 0.6-1.2 | 5.5/1.1 | 1373 |

| SF-2.8 | 2.8 | 1700×1600×1150 | 550 | 268 | 1.5-3.5 | 11/1.5 | 2138 |

| SF-4 | 4 | 1850×2050×1200 | 650 | 220 | 2–4 | 15/1.5 | 2582 |

| SF-8 | 8 | 2200×2900×1400 | 760 | 191 | 4–8 | 30/1.5 | 4129 |

| SF-10 | 10 | 2200×2900×1700 | 760 | 191 | 5–10 | 30/1.5 | 4486 |

| SF-16 | 16 | 2850×3800×1700 | 760 | 191 | 5–16 | 30×2/1.5 | 8320 |

| SF-20 | 20 | 2850×3800×2000 | 760 | 191 | 5–20 | 30×2/1.5 | 9829 |