Rotary Scrubber

Capacity: 1-400 TPH

Process Material: Gold dredger, quartz mine, limonite ore, nonferrous ore, construction use sand and gravel washing, etc.

Rotary Scrubber Overview

Gold trommel scrubber, also known as rotary screen ore washer, or cylinder screen washer. It is a multi-purpose hydraulic cleaning soil, sticky mud equipment which is both have a cleaning function and a screening function. That is, the trommel scrubber machine not only can preliminary clean the raw materials but also sieves them by particles.

The trommel washing machine is placed before a crusher, gravity separator, magnetic separator, and flotation to avoid clogging and improve beneficiation efficiency.

Rotary Scrubber Types

JXSC supplies two types of gold trommel scrubber machines: the fixed type rotary scrubber and mobile rotary scrubber.

Our Rotary Scrubber for Sale

- Screen Mesh: Mesh size 8 – 50mm.

- Screen Material: PU or manganese or stainless steel, 1 layer, 2 layers.

- Liner Plate: Natural rubber, spiral welded steel plate.

Advantages

Rotary Scrubber Advantages

- Trommel scrubber with a good function of washing and screening.

- High production capacity (can be from 1T/H to 250 T/H).

- Low operating costs, easy maintenance, and low noise.

- The length diameter of the drum, screen mesh, mesh layer, liner plate, portable or stationary, and drive tire material are customizable. Small-scale gold wash plants and mini gold trommel are available.

- With Rubber tires driving, water spray pipes inside the screen.

Structures & Working Principle

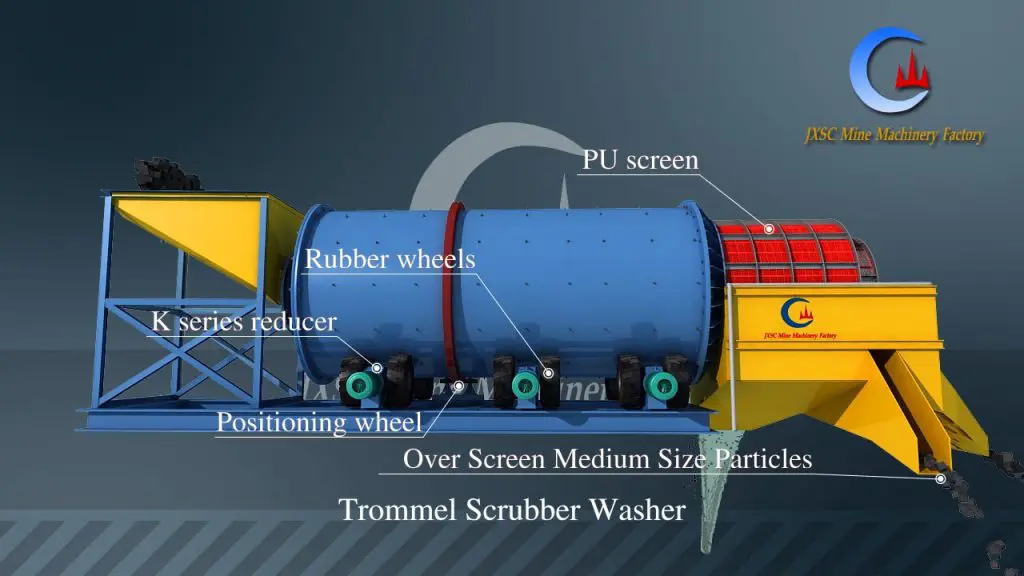

Rotary Scrubber Structure

Trommel scrubber washer machine with two parts: drum scrubber and screen. The drum scrubber is for washing ore, the screen is for sieving different size particles after washing.

Rotary Scrubber Working Principle

A high-pressure flushing water pipe is arranged in the longitudinal direction of the cylinder. The rotation of the cylinder screen causes the ore to turn over and collide with each other, and with the hydraulic scouring, the clay is broken and cleaned.

The washing effect increases with the residence time of the ore in the return screen, the water pressure of the spray water, and the water consumption. In order to strengthen the mechanical action of the equipment, longitudinal steel bars for loose ore can be installed on the inner wall of the cylindrical sieve.

Technical Parameters

| Model | Drum Dia (mm) | Drum & Screen Length (m) | Screen Mesh Size (mm) | Rotation Speed (r/min) | Feeding Size (mm) | Angle of Inclination(°) | Capacity (t/h) | Power (kW) |

| JXSC-400 | 400 | 2m+1.2m | ≤20 | 27.9 | ≤80 | ≤10 | 1-5 | 3 |

| JXSC-600 | 600 | 2m+1.2m | ≤25 | 27.6 | ≤80 | ≤10 | 5-10 | 4 |

| JXSC-750 | 750 | 2.5m+1.5m | ≤25 | 27.6 | ≤100 | ≤10 | 10-20 | 5 |

| JXSC-900 | 900 | 3m+1.8m | ≤25 | 27.6 | ≤100 | ≤10 | 20-40 | 11 |

| JXSC-1200 | 1200 | 4m+2m | ≤25 | 17 | ≤100 | ≤10 | 40-70 | 15 |

| JXSC-1500 | 1500 | 4m+2m | ≤50 | 16 | ≤100 | ≤10 | 70-100 | 30 |

| JXSC-1800 | 1800 | 4m+2m | ≤50 | 16 | ≤100 | ≤10 | 100-150 | 18.5*2 |

| JXSC-2100 | 2100 | 4m+2m | ≤50 | 16 | ≤1000 | ≤10 | 150-200 | 22*2 |

| JXSC-2400 | 2400 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 200-250 | 22*4 |

| JXSC-2700 | 2700 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 250-270 | 55*2 |

| JXSC-3000 | 3000 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 270-300 | 30*4 |

| JXSC-3200 | 3200 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 300-340 | 37*4 |

| JXSC-3400 | 3400 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 340-370 | 45*4 |

| JXSC-3600 | 3600 | 6m+2.5m | ≤50 | 16 | ≤100 | ≤10 | 370-400 | 55*4 |