Roller Mud and Stone Screen

Capacity: 0-1000 T/H

Feeding Size: <45 mm

Shaft Number: 6-20 pcs

Applicable Materials: Mud and stone separation, soil and stone separation, sand and stone separation, large and small stone separation, coal and gangue separation, construction waste separation, etc.

Roller Mud and Stone Screen Machine Overview

The roller mud and stone screen machine is a new generation of self-cleaning special equipment, mainly used for screening and separating materials with high moisture content and high viscosity such as mud, earth and stone, sand and gravel, ore, coal mine, coal, construction waste, and domestic waste. It’s also known as soil rock stone separator, mud and stone separator, roller separator, roller screen, roller screen separator, butterfly screen, etc., The mud-rock separator is widely used in mining, chemical industry, construction, coal mining, and other fields.

Roller mud and stone screen/separator applications

- Soil and stone separation in aggregate plant

- Ore separation in mineral processing plant

- The dirt, brick, and concrete block separation in construction waste project

- The slag, and stone separation in the earthworks

The mobile mud and stone separator, also called mobile undulated roller screening station, is a kind of equipment for separating materials consisting of sludge and different sizes of stones. This equipment is especially for high mud content, mud-wrapped stone or stone containing mud, water content, high viscosity, difficult to separate, stone block large and other complex sand and gold ore raw materials to carry out effective scientific screening, through the separation of mud and stone, will be wrapped in the mud inside the gold cleaning out, so that it improves the gold recovery rate, to achieve the effective use of resources. The portable mud and stone separator is usually placed at the front end of the process, directly screening out the large amount of soil contained in the material, while the large pieces of material are sent to the next process for processing by the belt conveyor.

Mobile Mud & Stone Separator

Mobile Roller Screen

Roller Mud And Stone Screen

In placer gold mining, to reduce the pressure on the gold processing system below and to improve gold recovery, it is necessary to screen out the lumpy material from the raw ore in advance and to break up the mud clusters and lumps. Some materials are sticky and wet. River pebbles and oxidized gold ore are usually encased in the mud. This new soil/mud rock stone separating and screening machine is used to process the ore material which is sticky and not easy to separate. During operation, the equipment continuously crushes and sieves, it is easier to disperse the material and reasonably increase the separation rate.

Advantages

Mud and Stone Separator Advantages

- High efficient separation while conveying and feeding materials at the same time.

- No need for water, solving the problem of environmental protection water.

- Complete models, or customize them according to needs.

- Can be used combined with the mobile crushing plant.

- Convenient high mobility, easy to transfer to the site.

- High screening efficiency, low noise, small dust, long service life

- The application range of mud and rock separators is extremely wide, and it is suitable for many fields such as sand and gravel plants, coal mining enterprises, metal mining, etc. Its versatility and adaptability enable various mineral resources to be developed and utilized more efficiently.

Structures & Working Principle

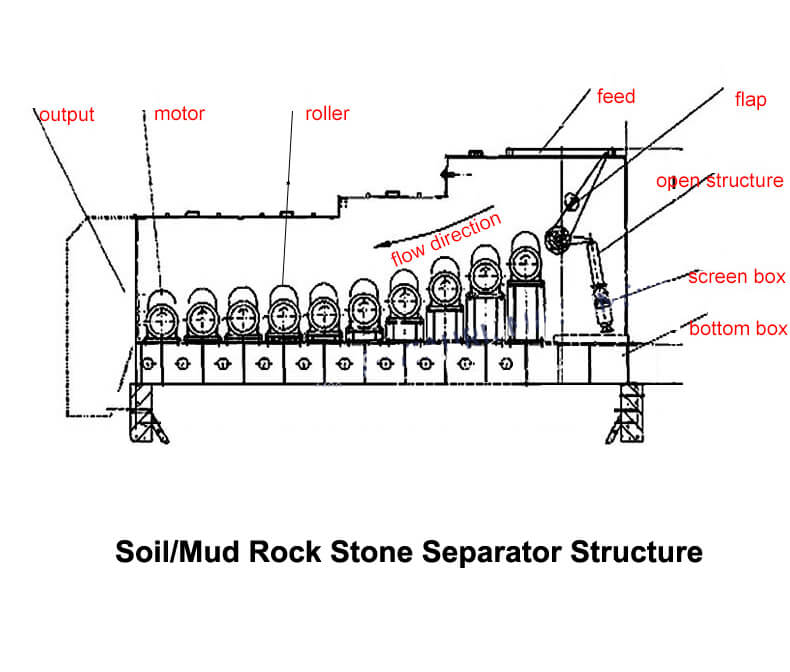

Roller Mud and Stone Screen Structure

The roller mud and stone screen is composed of a frame, bottom box, screen box, opening structure, flap, motor, reducer, roller, disc, and so on.

Mud and Stone Separator Working Principle

The mud and stone separator separates the materials through a multi-stage linked tumbler screen. The material enters the multi-stage linked roller screen from the top of the machine. The screen shafts of the irregularly shaped devices are driven by a motor to carry out tumbling movements. There is a gap between the shafts, and the irregular device embedded in the shafts supports the large size material to move forward, while the small size material gradually falls to the bottom of the machine and is discharged by the belt conveyor, thus realizing the separation of coarse and fine materials.

Technical Parameters

| Model | Power (kw) | Shaft Clearance (mm) | Shaft Number (pcs) | Inlet Size (mm) | Capacity (t/h) | Reference Weight (t) |

| 0816 | 7.5-11 | 10-50 | 6-8 | <20 | 30-100 | 4 |

| 1012 | 11-15 | 10-50 | 7-10 | <25 | 60-180 | 7 |

| 1230 | 18.5-30 | 15-70 | 8-11 | <30 | 100-300 | 12 |

| 1235 | 22-37 | 20-80 | 10-13 | <30 | 130-350 | 13 |

| 1340 | 37-45 | 20-90 | 11-14 | <33 | 150-500 | 16 |

| 1445 | 45-55 | 25-100 | 12-15 | <35 | 180-600 | 20 |

| 1550 | 55-75 | 25-100 | 13-17 | <38 | 200-700 | 23 |

| 1665 | 75-90 | 30-100 | 14-18 | <40 | 250-800 | 28 |

| 1860 | 75-110 | 30-100 | 15-20 | <45 | 350-1000 | 35 |