Precious Metal Recovery Equipment

Wastewater Treatment Capacity: Silver 6000-18000 liters/month; gold 3000-9000 liters/month

Application: Recovery of precious metals (gold, platinum, and palladium) from wastewater, recycling solution, and rinsing solution of plating process in semiconductor and electronic parts manufacturing.

Precious Metal Recovery Equipment Overview

In the production of semiconductors and electronic parts, plating wastewater, recycling solutions and rinsing solutions often contain precious metals such as gold (Au), platinum (Pt) and palladium (Pd). Recovery of these precious metals not only has economic benefits, but also reduces pollution of the environment. The recovery of these precious metals is generally achieved using a variety of processes, such as electrowinning, resin adsorption, precipitation, and so on. Wastewater recycling equipment containing precious metals(gold, silver, palladium) usually needs to be combined with a variety of recycling technologies for efficient treatment of different precious metals with respect to their physicochemical properties.

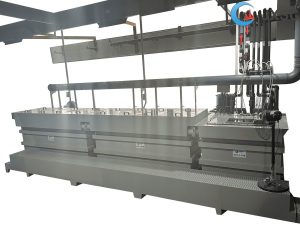

Electrolytic Precious Metal Recovery Equipment

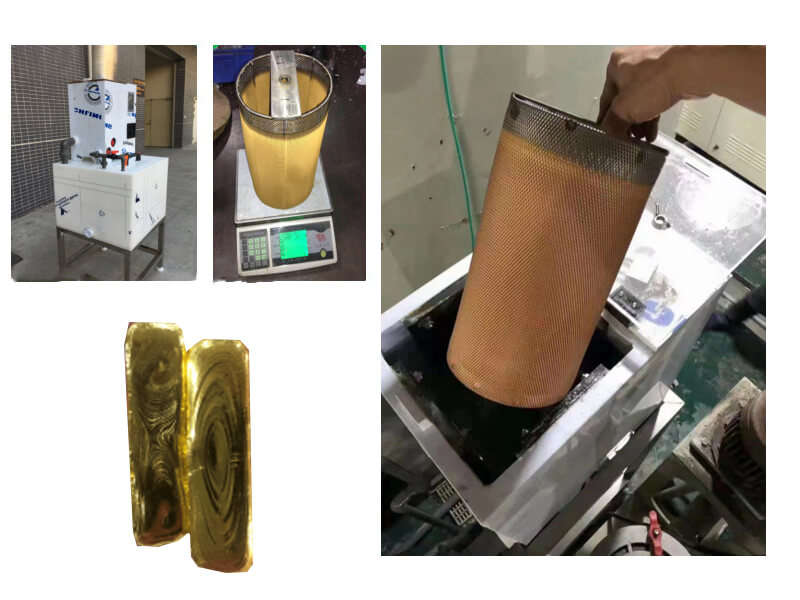

Electrolysis is one of the main methods used to recycle precious metals in wastewater with high concentrations of gold, silver, and palladium. The Electrolytic precious metal recovery machine (EPMRM) is equipment specially designed for extracting precious metals such as gold, silver, palladium, etc. from wastewater or solutions containing precious metal ions. It’s also called a gold and silver electrolysis recovery machine. The machine adopts the principle of electrolytic deposition, and through an electrochemical reaction, the precious metal ions in the solution are reduced to metal and deposited on the cathode surface. The electrolytic precious metal recovery machine is used for wastewater with high concentrations of precious metals, especially gold, silver, and palladium wastewater from the electronics, jewelry, and electroplating industries.

Electrolytic precious metal recovery equipment Application scope

- Gold, silver, platinum, rhodium, and palladium ions in electroplating wastewater.

- Gold, silver, platinum, rhodium, and palladium ions in electroplating cleaning tank wastewater.

- Gold and silver rhodium palladium ions in a gold etching solution of the circuit board.

- Gold and silver ions in the stripping leaching solution of electronic scrap.

- Silver ions in fixing solution bleaching solution.

Advantages

Precious Metal Recovery Equipment Advantages

- Pulse electrodeposition recovery uses only a small amount of electricity (150~250W).

- No additives, no secondary pollution.

- Small and compact size, easy to operate, no need to be supervised.

- Full anti-corrosion design, long service life.

- The equipment does not need any consumables and the electrolytic accelerator, operation, and maintenance costs are very low.

- Large treatment capacity, after combination, the monthly treatment of silver-containing wastewater can be more than 6000-180000, gold-containing wastewater treatment capacity halved.

- The recovery rate reaches more than 99%, and can directly extract the purity of 95-99.8% of gold.

- The content of precious metals in the waste liquid after treatment: silver can be lower than 5-20ppm, gold can be lower than 2-10ppm.

Structure & Working Principle

Structure

Electrolytic equipment for precious metal recovery is structurally sophisticated and designed to efficiently extract precious metals from wastewater or solution. Typical Electrolytic equipment contains components such as electrolytic cells, anodes and cathodes, power supply systems, fluid circulation systems, etc., each of which plays an important role in the recovery process.

Working Principle

Electrowinning is a process that recovers precious metals (e.g., gold, silver, etc.) from solution through an electrolytic chemical reaction. In the electrodeposition process, when current passes through a solution, electrons in the current chemically reduce metal ions to form solid metal compounds on the cathode (negatively charged electrode), thus depositing the metal in a form that is easily melted. Precious metal recovery equipment adopts electrodeposition technology to reduce precious metal ions (such as gold, silver, platinum, nickel, etc.) in wastewater to high-purity precious metals, while reducing the metal-containing star in the solution to 2~5ppm, realizing considerable economic and environmental benefits.

Technical Parameters

| Model | Waste Liquid Treatment Capacity (liters/day) | Voltage (V) | Power (W) | |

| Silver | Gold | |||

| RY200 | 150-200 | 100-150 | 220 | 300 |

| RY400 | 300-500 | 200-350 | 220 | 350 |

| RY600 | 500-800 | 300-500 | 220 | 400 |

| RY800 | 600-1000 | 500-800 | 220 | 500 |