Plate High Gradient Magnetic Separator

Capacity: 8-35 t/h

Power: 1.5-3 kW

Application Materials: Limonite, hematite, ilmenite, garnet, carborundum, etc.,

Plate High Gradient Magnetic Separator Overview

The plate high gradient magnetic separator is mainly suitable for the magnetic separation of weakly magnetic minerals with a particle size of less than 5MM and the iron removal of non-metallic minerals, such as mica powder, quartz sand, potassium feldspar, nepheline, fluorite, sillimanite, Spodumene, kaolin, manganese ore, weak magnetite, pyrrhotite, roasted ore, ilmenite, hematite, limonite, siderite, ilmenite, chromite, wolframite, da Silver ore, red mud, etc. It can also be used for iron removal operations in coal, non-metallic minerals, building materials, and other materials.

This product is our latest research and development of high gradient and high-intensity magnetic separation equipment. It breaks the conventional design concept, combining magnetic separation and re-election in one, high magnetic field (10000-15000GS) design. It has the advantages of high magnetic field, low energy consumption, simple and convenient debugging, and few wearing parts.

Features

- Advanced Design & Structure

plate type high gradient magnetic separator adopts advanced computer simulation design and pole-shaped arrangement structure which can effectively protect the working range and working capacity. - NdFeB Rare Magnetic Material

Magnetic material all adopts NdFeB rare earth to form the strong magnetic core. The purity is high, the amount is large, and the magnetism is strong which can achieve 15000Gs. It is a revolutionary breakthrough in the field of high-gradient magnetic separators, also the performance is in the lead. - Optimized Design

The whole machine adopts an optimized design that can protect against oxidation and the magnetic system is fully sealed. The magnetism of a strong magnetic core consumes no more than 5% within ten years and does not affect normal use. - Endless-speed Motor

The driving part adopts an endless-speed motor with excellent performance, fully automatic continuous operation, and unloading of iron, saving manpower, and operating reliably without failure. - Feeding System

The feeding system uses a motor agitation structure which makes the material in the magnetic separation zone well-distributed also slurry concentration meets the processing requirements to make the separation effect more effective. - Water System

The whole water system uses a single water inlet, each valve controls the water point. It is convenient for customers to operate with water equipment, each valve can open and adjust water consumption according to actual needs. - Passed and Touched Area Material

The area material passed and touched adopts stainless steel and non-magnetic material which can avoid the second pollution of the material. If necessary, some important parts can do wear-resistant treatment. - Open/Fully Sealed Structure

The whole structure has two forms open or fully sealed structure according to the field conditions also can suitable to different requirements.

Advantages

Plate High Gradient Magnetic Separator Advantages

- The magnetic circuit design is unique, the magnetic field intensity is high, and the surface magnetic field strength can reach 15000GS.

- Compared to the other permanent magnetic separation of the magnetic field, the magnetic separation effect is better.

- Compared to other high gradient magnetic separators energy saving, is power saving.

- The structure is simple, reasonable, easy to use, low maintenance rate.

- Fully automatic continuous operation, and unloading of iron, saving manpower, and operating reliably without failure.

- Effectively protect the working range and working capacity.

Structures & Working Principle

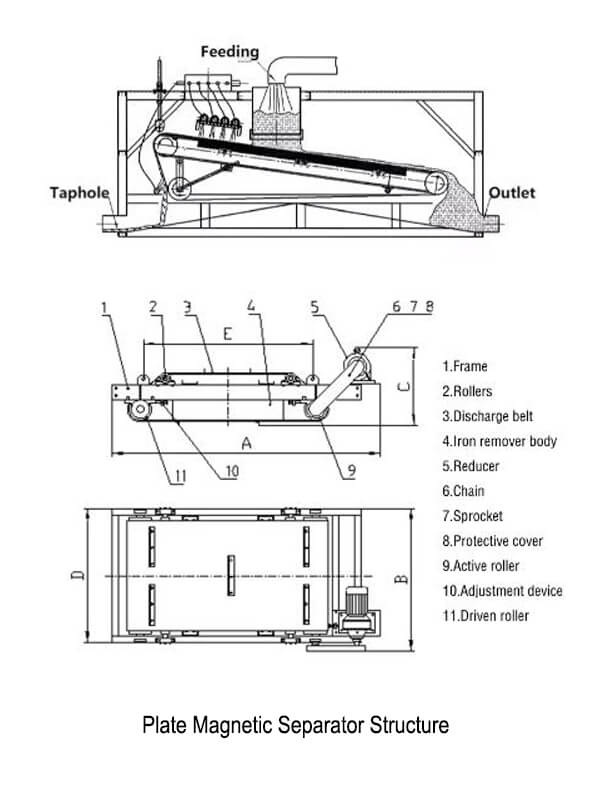

Plate Magnetic Separator Structure

Plate type high gradient magnetic separator consists of a frame, plate-type magnetic system, feed mixing system, water system, iron unloading system, and regulatory system.

Plate Magnetic Separator Working Principle

When working, the material flow and unloading system is in a reverse counterflow. According to the physical structure principle, the non-magnetic material flows to the discharging port to achieve a complete unloading purpose by washing. The magnetic material is attracted by strong magnets for long distances, wide areas, and multiply-frequency, and be taken to tapping hole in reverse running by unloading system, then to achieve complete unloading purpose by washing.

Technical Parameters

| Model | Width (mm) | Length (mm) | Capacity (t/h) | Power (kW) | Dimensions (mm) | Weight (t) |

| 600×2000 | 600 | 2000 | 8-10 | 1.5 | 4000x1000x1800 | 2.4 |

| 800×2000 | 800 | 2000 | 10-13 | 1.5 | 4000x1200x1800 | 2.6 |

| 1000×2000 | 1000 | 2000 | 13-18 | 1.5 | 4000x1200x1800 | 2.8 |

| 1200×2500 | 1200 | 2500 | 18-25 | 1.5 | 4500x1600x1800 | 3 |

| 1500×2500 | 1500 | 2500 | 25-30 | 2.2 | 4800x1900x1800 | 3.5 |

| 2000×2000 | 2000 | 2000 | 30-35 | 3 | 4000x2400x1800 | 3.8 |

| 2000×2500 | 2000 | 2500 | 30-35 | 2.2 | 4800x2400x1800 | 4 |