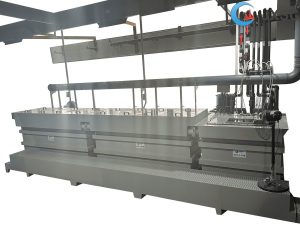

Micro Etching Liquid Recycling And Copper Extraction Equipment

Waste Liquid Treatment Capacity: 0-200 Tons/Month

Copper Production Capacity: 0-5 Tons/Month

Electricity Load: 20-100 kW

Micro Etching Fluid & Copper Recycling Equipment Overview

Micro-etching is the circuit board production process of grinding board, electroplating, coppering, nickel gold immersion, oxidation (OSP) and tin spraying and other processes, the purpose is to roughen the copper surface, increase the bonding force with the plating layer. Treatment process with sodium persulfate / sulfuric acid, ammonium persulfate / sulfuric acid or hydrogen peroxide / sulfuric acid and other systems, sodium persulfate, ammonium persulfate and hydrogen peroxide play a role in increasing the oxidation value of the micro etching solution to improve the oxidizing ability of the potion, to achieve the effect of rapid etching of copper. However, when the copper ion concentration in the micro-etching solution reaches a certain value (15g/L), the etching ability is significantly weakened, the need to change the tank or regeneration, and the waste liquid needs to be discharged or regenerated for reuse.

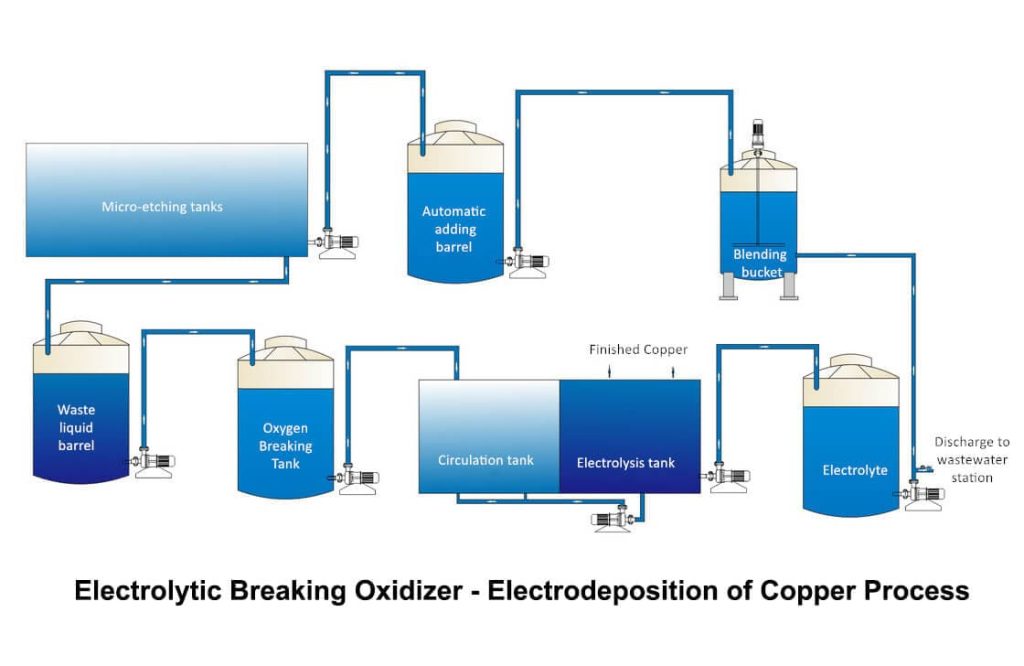

Micro-etching fluid recovery and copper extraction equipment is for micro-etching systems on the copper surface processing of the waste liquid generated by the electrolytic treatment equipment. Adopt electrolysis to break the oxidizer – electrodeposition copper process to deal with micro-etching waste liquid. The treated waste liquid is sulfuric acid waste liquid with copper ion concentration less than 0.5g/L containing 5%, which achieves the purpose of recovering copper and reuse of medicinal water, and greatly reduces the pressure of environmental protection treatment.

The micro etching waster liquid copper recycling equipment has the advantages of equipment occupies a small area, small investment, simple and easy to operate. The electric efficiency is 70%, with no other auxiliary additives, and low cost.

Product/System Features

- The process of electrodeposition of copper is to reduce Cu2+ to elemental copper by using the equipment after the oxidant is reduced to the electrode cathode.

- Reducing the concentration of Cu2+ wastewater treatment is easy to reduce the environmental treatment of Cu2+ pressure, and in the process to get the economic value of the by-product – electrolytic plate copper to reduce copper.

- The copper ions in the waste etching solution can be recovered and reduced to electrolytic copper powder with high purity and higher copper recovery.

- High production efficiency, small cover area.

Structure/Working Principle

The micro etching liquid recycling and copper extraction equipment includes a waste liquid collection tank, oxygen-breaking liquid storage tank, filtration system, oxygen-breaking tank, storage tank, electrolysis tank, copper-free waste liquid storage tank, plate copper storage tank, and circulation tank.

The process of electrolytic breaking oxidizer – electrodeposition of copper was used to treat the waste liquid of microerosion. Electrolytic oxidizer breaking process is to use the equipment after the use of micro corrosion waste liquid in the electrode cathode reduction, so that sodium persulfate, ammonium persulfate and hydrogen peroxide oxidants are reduced from a high concentration to 0. Electrodeposition of copper process is in the oxidant reduced to 0, the use of equipment to make the micro-etching waste liquid in the electrode cathode under the action of the reduction of Cu2+ reduction to a single copper, so that the concentration of waste liquid Cu2+ reduced by more than 95% of the easy wastewater treatment and discharge to reduce the pressure on environmental protection to deal with the Cu2+ and in the process of the by-products of economic value — Electrolytic plate copper (purity greater than 99.95%).

Technical Parameters

| Model | Waste Liquid Treatment Capacity (Tons/Month) | Electricity Load (kW) | Copper Production Capacity (Tons/Month) | Occupied Area(m2) |

| YZ-WSDJ30 | 30 | 20-30 | 0.75 | 30-30 |

| YZ-WSDJ60 | 60 | 40-50 | 1.5 | 30-40 |

| YZ-WSDJ100 | 100 | 60-70 | 2.5 | 60-70 |

| YZ-WSDJ200 | 200 | 80-100 | 5 | 80-100 |