Log Washer

Capacity: 10-150 T/H

Feeding Size: ≤70 mm

Process Material: Manganese, iron, limestone, tungsten, tin ore, and silica sand ore

Application: Mining, coal, smelting, and other industries.

Log Washer Overview

A log washer is used to wash ores with mud before the employment of mineral processing technology as well as increase ore dressing indexes of back-end technology. They often wash ores like manganese, iron, limestone, tungsten, tin, and silica sand ore.

Log Washer is ideal for scrubbing difficult washing minerals, tough insoluble clays, conglomerates, soft stones, and certain cemented aggregates that are too difficult to clean properly in normal screw machines. The log washer thoroughly scouring, breaks down, and cleans the toughest materials. If the mud content in the ore is more than 20%, it will block the crusher and the chute. The log washer can make the ore containing more than 20% mud be spirally stirred and scrubbed in the ore washer to separate the ore and soil. It is widely used for washing various easy-to-wash and difficult-to-wash ores.

The log washer is suitable for cleaning the sediment before beneficiation of iron, manganese, limestone, tin ore, and other ores with a significant mud content. It is mainly used for stirring, washing, separating, and desliming the minerals. It is also suitable for cleaning stones in buildings, power stations, and other engineering projects. The flushing water pressure is <147-196kpa.

Our Log Washer Features

- Simple structure and stable operation.

- Separate the bearings from water and materials to avoid premature damage to the machine caused by contamination and rust.

- Suitable for various working environments.

- There is less loss of washed materials and high washing efficiency, which can fully meet the requirements of high-grade materials.

- The service life is relatively long and there are almost no wearing parts.

- With the three functions of sand washing, grading, and dehydration.

- The sand washing machine is 10°~14° tilted layout.

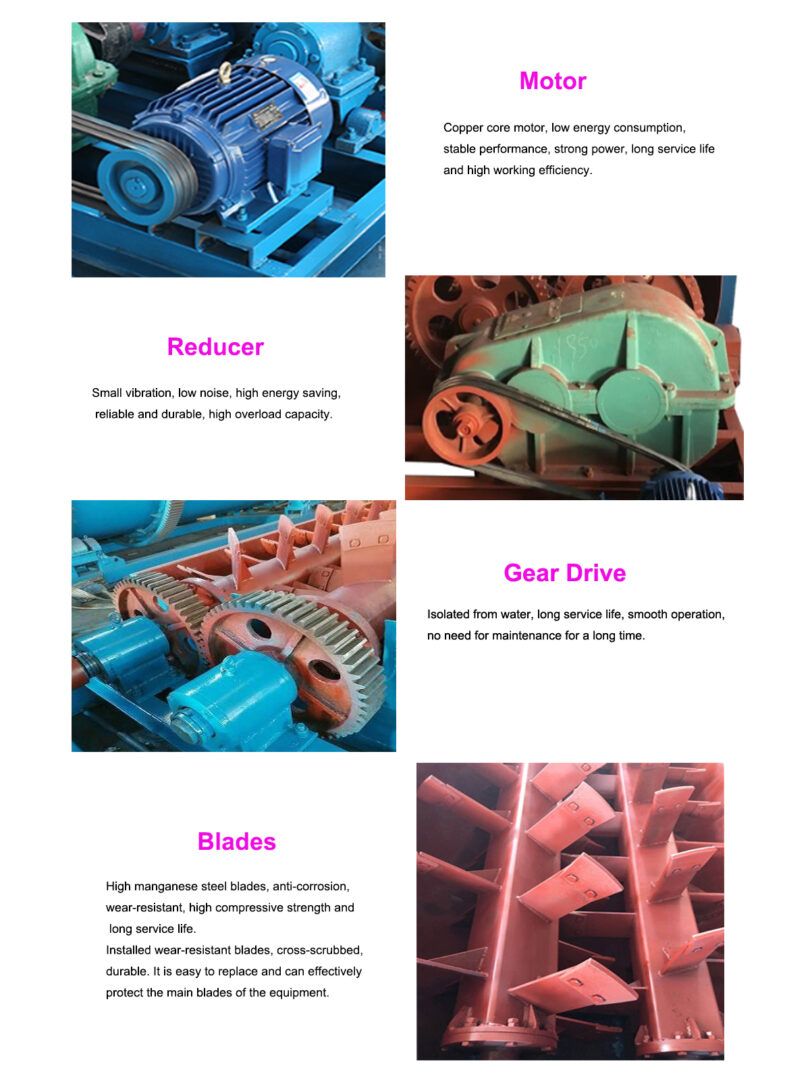

Our Log Washer Details

- Motor

Copper core motor, low energy consumption, stable performance, strong power, long service life, and high working efficiency. - Reducer

Small vibration, low noise, high energy saving, reliable and durable, high overload capacity. - Gear Drive

Isolated from water, long service life, smooth operation, no need for maintenance for a long time. - Blade

High manganese steel blades, anti-corrosion, wear-resistant, high compressive strength, and long service life.

Installed wear-resistant blades, cross-scrubbed, durable. It is easy to replace and can effectively protect the main blades of the equipment.

The log washer is used alone or in conjunction with the belt conveyor. This equipment cooperates with the cylinder washing machine and is a relatively effective washing equipment for processing difficult-to-wash ores.

Advantages

Log Washer Advantages

- Effective Cleaning

Log washers are highly efficient at removing impurities from raw materials, such as clay, silt, and organic matter. They use the abrasive action of logs or paddles to break down and disintegrate these materials, allowing for better separation. - Improved Product Quality

By removing impurities, log washers can significantly improve the quality of the final product. For example, cleaner materials can produce better concrete markers in the aggregates industry. - Increased Production Rates

Log washers can quickly handle large volumes of material, leading to increased production rates. It is precious in industries where high throughput is essential. - Versatility

We can use the log washers with various materials, including ores, aggregates, and minerals. They are versatile and can adapt to different materials and feed sizes. - Reduces Wear and Tear on Downstream Equipment

By removing abrasive materials early in the processing chain, log washers help extend the life of downstream equipment such as crushers and screens. It can lead to cost savings through reduced maintenance and equipment replacement. - Water Conservation

Log washers typically operate in a closed-loop system, meaning the water used in the washing process can be recirculated and reused. It can help conserve water resources and reduce water consumption. - Energy Efficiency

Log washers are generally designed to be energy-efficient. They rely on mechanical action and gravity, reducing the need for excessive energy input. - Easy Maintenance

Log washers are relatively simple machines with few moving parts. It makes them easier to maintain and reduces downtime for repairs. - Scalability

Log washers come in various sizes and configurations, allowing scalability to match different operations’ production needs. - Environmental Benefits

By removing contaminants early in the process, log washers can help minimize the environmental impact of mining and processing operations by reducing the release of harmful materials into the environment.

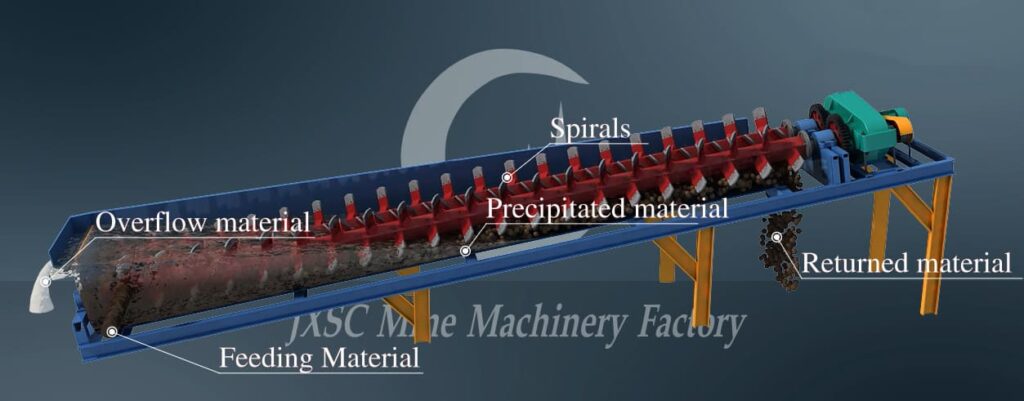

Structures & Working Principle

Log Washer Structure

The log washer is mainly composed of a transmission device, a spiral, a tank body, a lower support, an overflow tank, etc.,

- Transmission device: It is the power for spiral work. The motor drives the spiral to rotate through the V-belt, reducer, and gear.

- Spiral: The main working part of the machine, which plays a role in stirring minerals. The main shaft is a square shaft welded by channel steel. The upper is installed on the frame of the transmission device, and the lower is installed on the lower support. The spiral blades are made of spring steel plates.

- Tank body: It is the machine’s body welded by various types of steel and steel plates.

- Lower support: Its function is to support the spiral shaft.

- Overflow tank: Discharge muddy water and debris.

Log Washer Working Principle

Material is fed into the hull of the log wash where it is spread into the base of the log and hit with significant water flow. At this point, the paddle design maneuvers the material up the log at a slight angle. Throughout this travel, the contents are agitated and the material-on-material attrition is used to liberate and clean the materials as they travel up the log. The silts and light fraction are floated down the log using a contraflow water system, ensuring a clean material is discharged from the mouth of the log washer.

Technical Parameters

| Model | Spiral Dia. (mm) | Rotating Speed (r/min) | Feeding Size (mm) | Tank Slope (°) | Capacity (t/h) | Motor Power(kw) | Weight (T) |

| 2RXL320 | 320 | 28 | ≤30 | ≤12 | 10 | 4 | 0.9 |

| 2RXL400 | 400 | 23 | ≤30 | ≤12 | 20 | 5.5 | 1.9 |

| 2RXL540 | 540 | 23 | ≤30 | ≤12 | 25 | 11 | 3.9 |

| 2RXL750 | 750 | 22.7 | ≤70 | ≤12 | 50 | 22 | 7.5 |

| 2RXL800 | 800 | 22 | ≤70 | ≤12 | 70 | 30 | 8.2 |

| 2RXL914 | 914 | 21 | ≤70 | ≤12 | 100 | 37 | 10.3 |

| 2RXL1200 | 1200 | 20 | ≤70 | ≤12 | 150 | 55 | 13.5 |