Hydrocyclone

Capacity: 0.1-900 m³ /h

Scope of Application: Ore pulp classifier

Process Material: Gold, chrome, tin, coltan, diamond, tantalite, silica sand, etc.

Hydrocyclone Overview

The hydrocyclone is a simple piece of equipment that uses fluid pressure to generate centrifugal force and a flow pattern that can separate particles or droplets from a liquid medium. These particles or droplets must have a sufficiently different density relative to the medium to achieve separation.

Hydrocyclone/ cyclone filter is mainly used for classification, separation, concentration, and desliming in the mineral mining industry. When the hydrocyclone is used as a classifier, it is mainly used to form a grinding and classification system with a mill; when it is used as a deslimer, it can be used for desliming in a gravity concentrator; when it is used as a concentrating and dewatering device, it can be used to concentrate ore dressing tailings and send them to fill underground mining tunnels. The hydro cyclone sand separator has no moving parts, a simple structure, a large capacity per unit volume, a small area, high classification efficiency (up to 80% ~ 90%), fine classification granularity, low cost, and low material consumption.

Hydrocyclone Types

The hydro cyclone separator has two types of pressure type and gravity type made up of either cylindrical structure or metal pipe. Water is fed through the top of the structure (or metal pipe) by means of pressure or gravity along the tangent line. Coarse and thick particulate matter are thrown to the wall, rotated down, and discharged together with the concentrated liquid formed under the action of centrifugal force. Small particulate matter is discharged together with secondary upward vortex after rotated to some extent.

Advantages

Hydrocyclone Advantages

Capable of separating fine material from liquid

Can separate liquid from liquid when large differences in specific gravity are present

Accepts variation in feed solids content

Consistent underflow densities

Adjustable underflow densities

Rubber-lined standard; ceramic lining optional

Structures & Working Principle

Hydrocyclone Structure

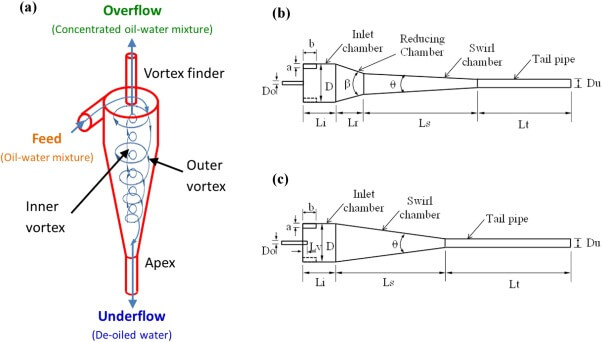

The structure of the hydrocyclone is relatively simple. The hydrocyclone consists of a hollow cylinder at the top and an inverted cone at the bottom, which is connected to the cylinder to form the hydro cyclone. In addition, the hydroclone also has feed pipes, overflow pipes, overflow conduits, and sinks.

Hydrocyclone Working Principle

The hydrocyclone pump (or height difference) rotates the slurry into the cylinder along the Tangent Direction with a certain pressure (generally 0.5 ~ 2.5 kg/cm) and flow rate (about 5 ~ 12 m / s), and then the slurry rotates along the cylinder wall at a very fast speed to create centrifugal force. Under the action of Centrifugal Force and gravity, the coarse and heavy ore particles are thrown out. The suspension enters the hydraulic cyclone at relatively high speed from the feed tube in a tangential direction and rotates from top to bottom. This motion is commonly referred to as external or descending swirl motion. The solid particles in the external swirl flow are separated from the suspension by Centrifugal Force and move down the wall of the device to discharge from the bottom outlet.

Technical Parameters

| Model | Diameter (mm) | Angle of Cone(°) | Diameter of Overflow Outlet (mm) | Diameter of Spigot (mm) | Max Feeding Size (mm) | Inlet Pressure (mpa) | Capacity (m3/h) | Separation Particle Size (um) | Overall Dimension | Unit Weight (kg) | ||

| Length (mm) | Width (mm) | Height (mm) | ||||||||||

| FX840 | 840 | 20 | 280~380 | 80~220 | 18 | 0.04~0.2 | 500~900 | 74~350 | 1700 | 1500 | 3700 | 1621 |

| FX750 | 750 | 45 | 180~290 | 85~175 | 16 | 0.04~0.2 | 400~500 | 74~300 | 1210 | 910 | 2680 | 1400 |

| FX710 | 710 | 45 | 175~270 | 80~165 | 16 | 0.03~0.2 | 350~450 | 74~250 | 1255 | 1185 | 1040 | 1250 |

| FX660 | 660 | 20 | 165~250 | 80~155 | 16 | 0.03~0.2 | 250~350 | 74~220 | 1140 | 1000 | 2920 | 800 |

| FX660 | 660 | 45 | 165~250 | 80~155 | 16 | 0.03~0.2 | 250~350 | 74~220 | 1140 | 1000 | 2000 | 995 |

| FX610 | 610 | 20 | 155~230 | 75~140 | 13 | 0.03~0.2 | 200~300 | 74~220 | 875 | 950 | 2560 | 550 |

| FX610 | 610 | 45 | 155~230 | 75~140 | 13 | 0.03~0.3 | 200~300 | 74~220 | 875 | 950 | 1810 | 600 |

| FX500 | 500 | 20 | 125~185 | 55~115 | 10 | 0.03~0.3 | 140-220 | 74~220 | 850 | 700 | 2050 | 380 |

| 15 | 74~150 | 850 | 700 | 2380 | 540 | |||||||

| 45 | 74~150 | 850 | 825 | 1630 | 430 | |||||||

| FX350 | 350 | 20 | 80~120 | 30~70 | 6 | 0.04~0.3 | 60~100 | 50~150 | 775 | 620 | 1765 | 208 |

| 15 | 50~120 | 775 | 620 | 1970 | 210 | |||||||

| FX300 | 300 | 20 | 60~115 | 20~50 | 5 | 0.04~0.3 | 45~85 | 50~150 | 498 | 485 | 1415 | 105 |

| 15 | 40~100 | 498 | 485 | 1642 | 169 | |||||||

| FX250 | 250 | 20 | 60~100 | 16~45 | 3 | 0.06~0.35 | 40~60 | 40~100 | 410 | 380 | 1215 | 75 |

| 15 | 40~100 | 410 | 380 | 1405 | 73 | |||||||

| 10 | 30~100 | 410 | 380 | 1788 | 85 | |||||||

| FX200 | 200 | 20 | 40~65 | 16~32 | 2 | 0.06~0.35 | 25~40 | 40~100 | 365 | 330 | 1030 | 45 |

| 15 | 30~100 | 410 | 330 | 1083 | 54 | |||||||

| 10 | 30~100 | 400 | 365 | 1490 | 60 | |||||||

| F150 | 150 | 20 | 30~45 | 8~22 | 1.5 | 0.06~0.35 | 11~22 | 30~74 | 310 | 265 | 820 | 29 |

| 15 | 30~74 | 310 | 265 | 878 | 30 | |||||||

| 10 | 30~74 | 310 | 265 | 1160 | 35 | |||||||

| FX125 | 125 | 17 | 25~40 | 8~18 | 1 | 0.06~0.35 | 8~15 | 20~100 | 260 | 218 | 620 | 10.2 |

| 8 | 20~74 | 260 | 218 | 870 | 33 | |||||||

| FX100 | 100 | 20 | 20~40 | 8~18 | 1 | 0.06~0.35 | 5~15 | 20~100 | 260 | 210 | 525 | 8.6 |

| 15 | 20~100 | 268 | 215 | 720 | 13 | |||||||

| 8 | 20~100 | 365 | 150 | 1065 | 23 | |||||||

| 5 | 20~100 | 365 | 150 | 1505 | 30 | |||||||

| FX75 | 75 | 15 | 15~22 | 6~12 | 0.6 | 0.1~0.4 | 2~5 | 20~74 | 240 | 230 | 420 | 2.2 |

| 5 | 5~40 | 240 | 230 | 778 | 6.5 | |||||||

| FX50 | 50 | 15 | 11~16 | 3~8 | 0.3 | 0.1~0.4 | 1~2 | 10~74 | 160 | 137 | 400 | 1.5 |

| 5 | 160 | 137 | 680 | 5.5 | ||||||||

| FX25 | 25 | 5 | 6~10 | 3~7 | 0.2 | 0.1~0.4 | 0.8~1.2 | 4~20 | 130 | 85 | 495 | 1.2 |

| FX10 | 10 | 4 | 3~4 | 2~3 | 0.2 | 0.2~0.4 | 0.1~0.2 | 2~10 | 30 | 30 | 195 | 2 |