Heavy-Duty Apron Plate Feeders

Capacity: 100-240 m3/h

Power: 15-45 kW

Speed: 0.05 m/s

Applicable Materials: Suitable for conveying materials with high humidity and high viscosity

Heavy-Duty Apron Plate Feeders Overview

The heavy-duty apron feeder is also called the plate feeder. As the name suggests, its function is to continuously and uniformly transport the materials in the storage bin or transfer funnel to the crusher, horizontally or tilted direction. In the batching device or transportation equipment. It is an essential raw material transportation equipment in many industrial industries.

The apron feeder is suitable for transporting some solid materials with high temperatures, large block sizes, sharp edges, and strong grindability. The apron feeder is an auxiliary equipment for transportation machinery. This machine is used in the crushing and grading workshops of large mineral processing plants and cement, In departments such as building materials, it is used as a silo to continuously and evenly feed materials to the primary crusher. It can also be used to transport materials with larger particle sizes and specific gravity over short distances. It can be installed horizontally or tilted, with a maximum inclination angle of 12 degrees. To prevent materials from directly hitting the feeder, the silo is required not to be empty.

Features

- The chain adopts the crawler chain used for bulldozers, which is safe reliable in operation, and easy to use. The chain links do not need to be filled with oil.

- The chain plate is an overlapping welded chain plate, which ensures no material leakage or deviation during use and has good wear resistance. In addition to the roller support, the chain belt is also equipped with slide rail support.

- The chain belt tensioning device is equipped with a buffer spring, which can slow down the impact load of the chain and extend the service life of the chain.

- The driving device is suspended on the main shaft of the machine and is not connected to the foundation, so it is easy to install and disassemble. It also has the advantage that the gear meshing performance of the reducer is not affected by the accuracy of the foundation.

- The drive adopts a large speed ratio orthogonal reducer, which reduces the lateral size of the machine and facilitates process layout.

- Through the electronic control device, the apron feeder can automatically adjust the feeding speed of the feeder according to the load of the crusher so that the crusher can receive materials evenly, the workload can be stable, and the system can be automated.

Advantages

Heavy-Duty Apron Plate Feeders Advantages

- Rigorous material selection

Use multiple specifications of materials: carbon steel, 201 stainless steel, 304 stainless steel, 316 stainless steel. - High hardness

It’s not easily deformed when subjected to pressure such as impact. - High load-bearing

It can carry larger loads and has a large conveying force. - Easy maintenance

The equipment has a simple structure and is easy to maintain. - Strong applicability

It can complete horizontal, inclined, and turning conveying on one conveying line.

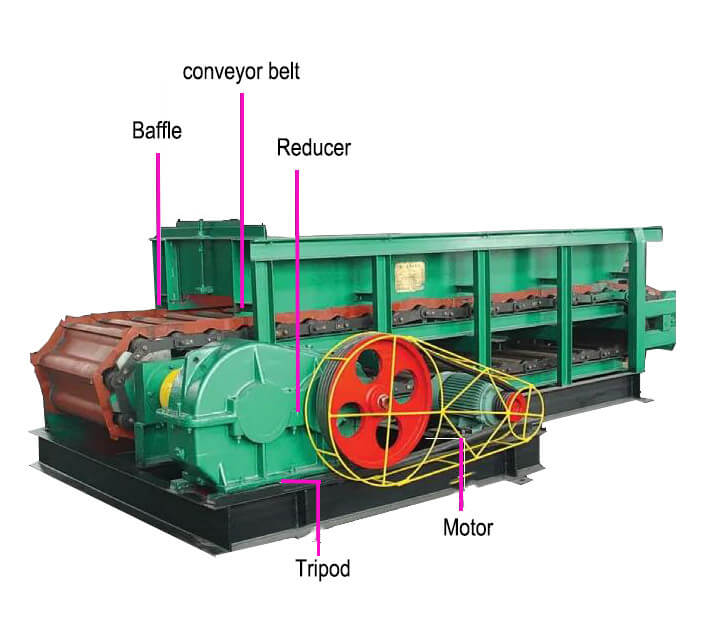

Structures & Working Principle

Heavy-duty Apron Plate Feeder Structures

The plate feeder is mainly composed of the head wheel assembly, frame, rotary body, driving device, chain roller, lower supporting wheel, tail wheel assembly, head cover, and other parts.

Heavy-duty Apron Plate Feeder Working Principle

The main power of the apron feeder is the motor. The motor is connected with the coupling to drive the reducer to drive the sprocket shaft to rotate. The transmission method adopts a sprocket chain structure. The sprocket chain mechanism can work under harsh working conditions. It is characterized by heavy load and low speed and can complete the transportation of heavy objects. The chain is used to drag the chain plate to move along a straight line. The chain plate is a support installed on the frame. The chain on the support of the heavy wheel and supporting wheel needs to be equipped with a corresponding tensioning device to ensure the correct meshing of the chain and sprocket to achieve the purpose of conveying materials.

Technical Parameters

| Model | Scraping Belt | Feeding Capacity(m3/h) | Motor Power (kW) | Weight(kg) | Overall Dimensions (mm) | ||

| Width(mm) | Center Distance of Sprocket(mm) | Speed(m/s) | |||||

| GBZ120-4.5 | 1200 | 4500 | 0.05 | 100 | 15 | 31279 | 6983*5228*2080 |

| GBZ120-5 | 5000 | 15 | 33427 | 7593*5228*2080 | |||

| GBZ120-5.6 | 5600 | 15 | 34321 | 8183*5228*2080 | |||

| GBZ120-6 | 6000 | 15 | 35900 | 8638*5228*2080 | |||

| GBZ120-8 | 8000 | 22 | 41342 | 10533*5293*2080 | |||

| GBZ120-8.7 | 8700 | 22 | 43164 | 11383*5293*2080 | |||

| GBZ150-4 | 1500 | 4000 | 150 | 15 | 33197 | 6613*5528*2080 | |

| GBZ150-6 | 6000 | 22 | 39257 | 8638*5593*2080 | |||

| GBZ150-7 | 7000 | 22 | 43352 | 9633*5593*2080 | |||

| GBZ150-8 | 8000 | 22 | 45962 | 10533*5593*2080 | |||

| GBZ150-9 | 9000 | 30 | 50522 | 11683*5668*2080 | |||

| GBZ180-8 | 1800 | 8000 | 240 | 45 | 51360 | 10533*6188*2080 | |

| GBZ180-9.5 | 9500 | 45 | 57397 | 12033*6188*2080 | |||

| GBZ180-10 | 10000 | 45 | 59632 | 12593*6188*2080 | |||