Gold Process Equipment

JXSC has very strict production management and advanced production technology in gold processing equipment. We own advanced cutting, automatic welding, and boring machines, which make our gold mining machine of high quality and good appearance.

JXSC has been engaged in the production and sales of gold process equipment since 1985. It is a professional China manufacturer of crushers and beneficiation equipment. The gold processing machines include sluice box, small-scale gold mining equipment, gold washing plant, trommel screen, and so on.

Gold Process Equipment for Sale

Gold Ore Processing Plant

Gold Ore Mining

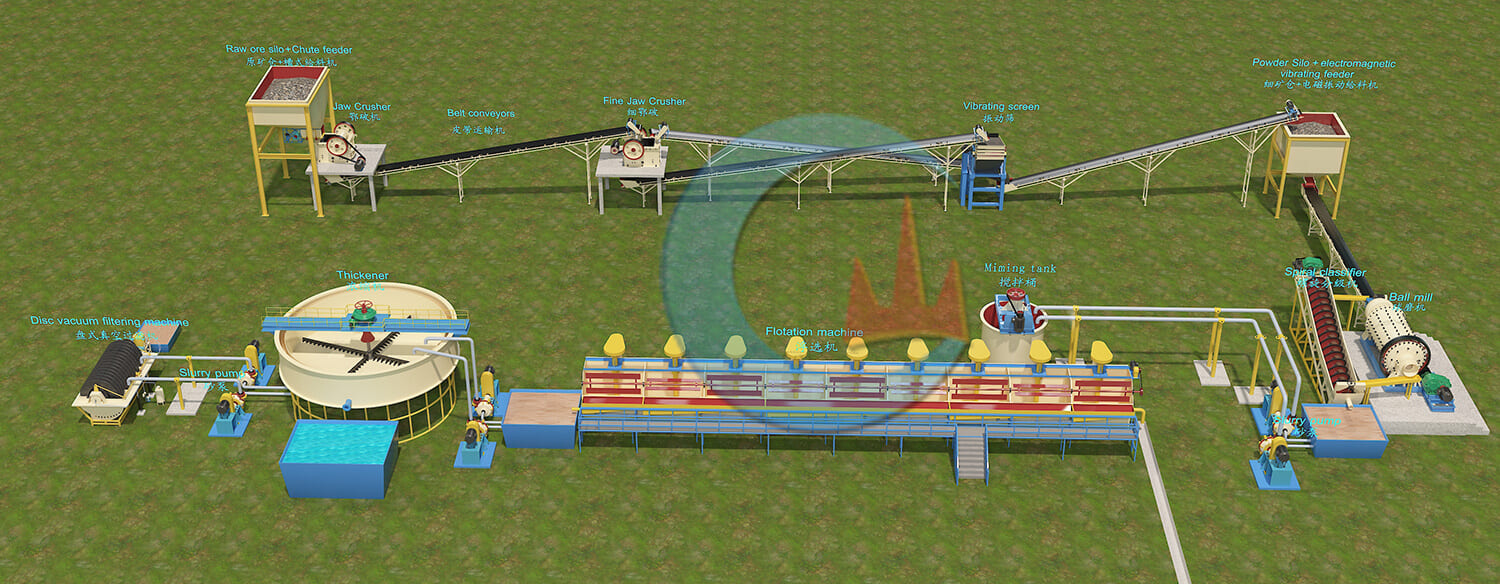

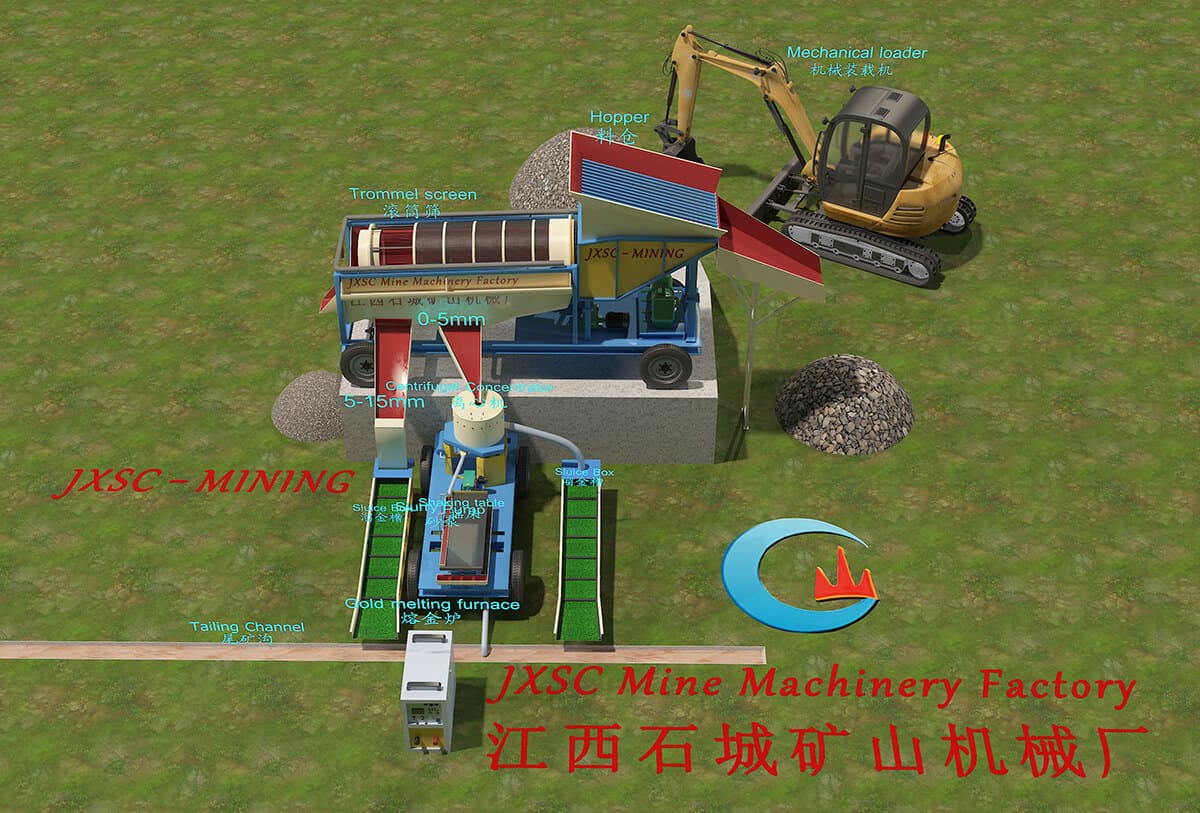

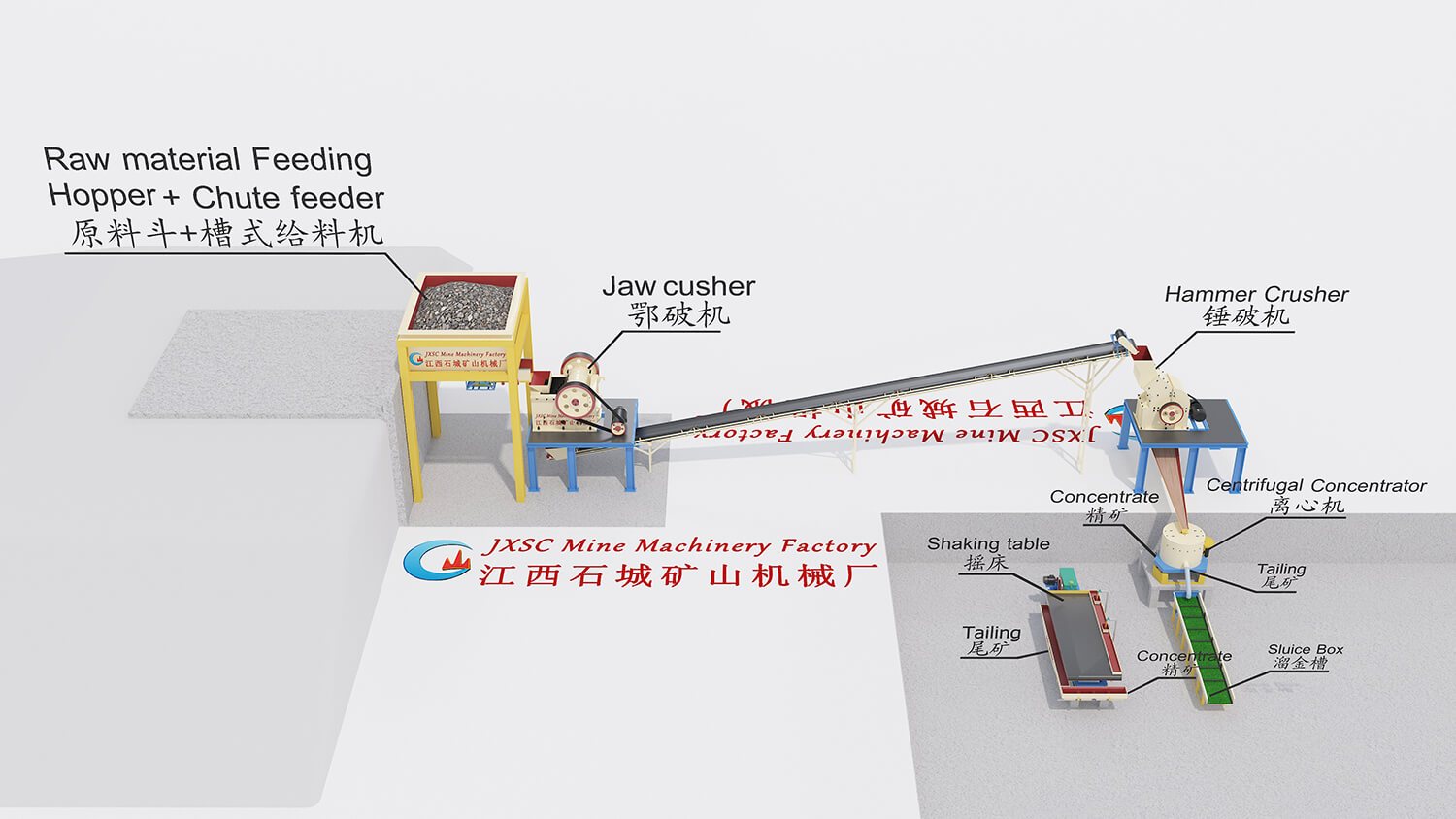

Placer gold mining mainly refers to mining from the land surface or river or underground. It mainly uses gravity separation because its density is much bigger than other minerals.

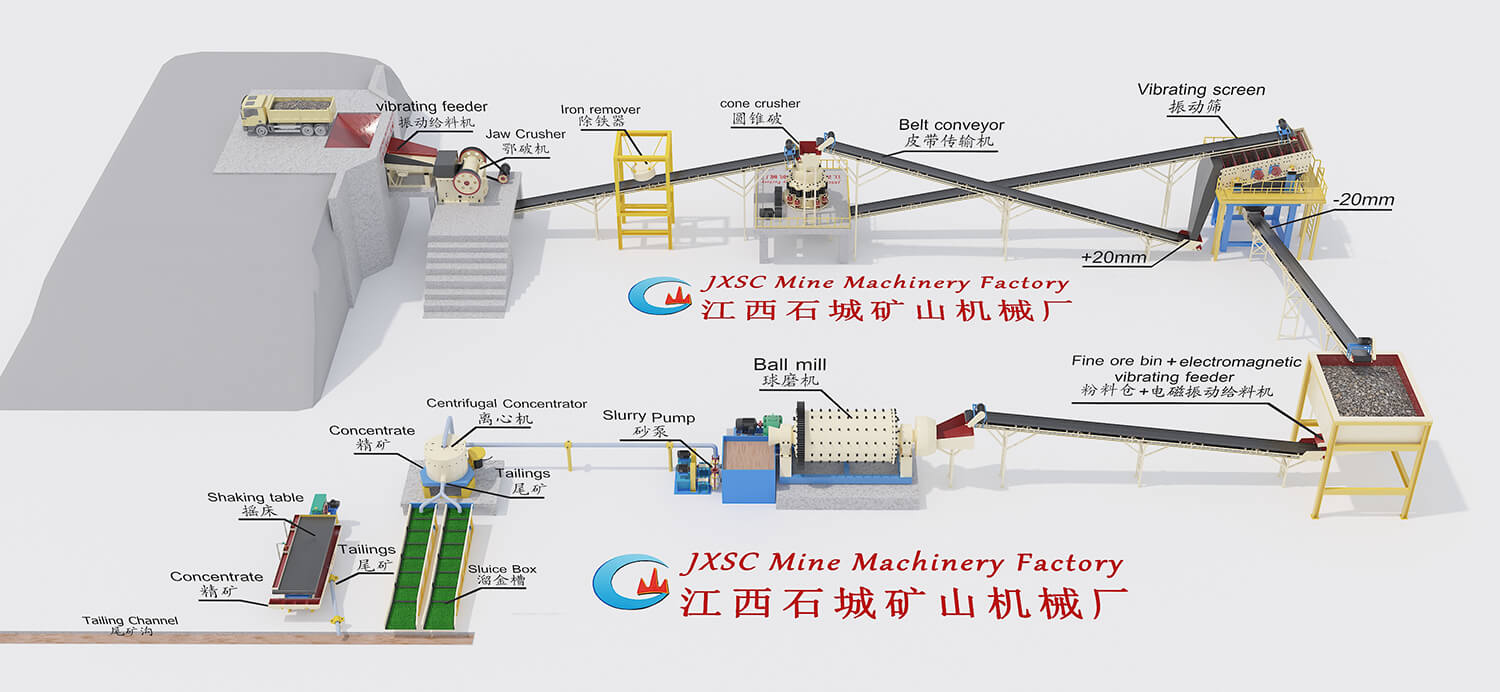

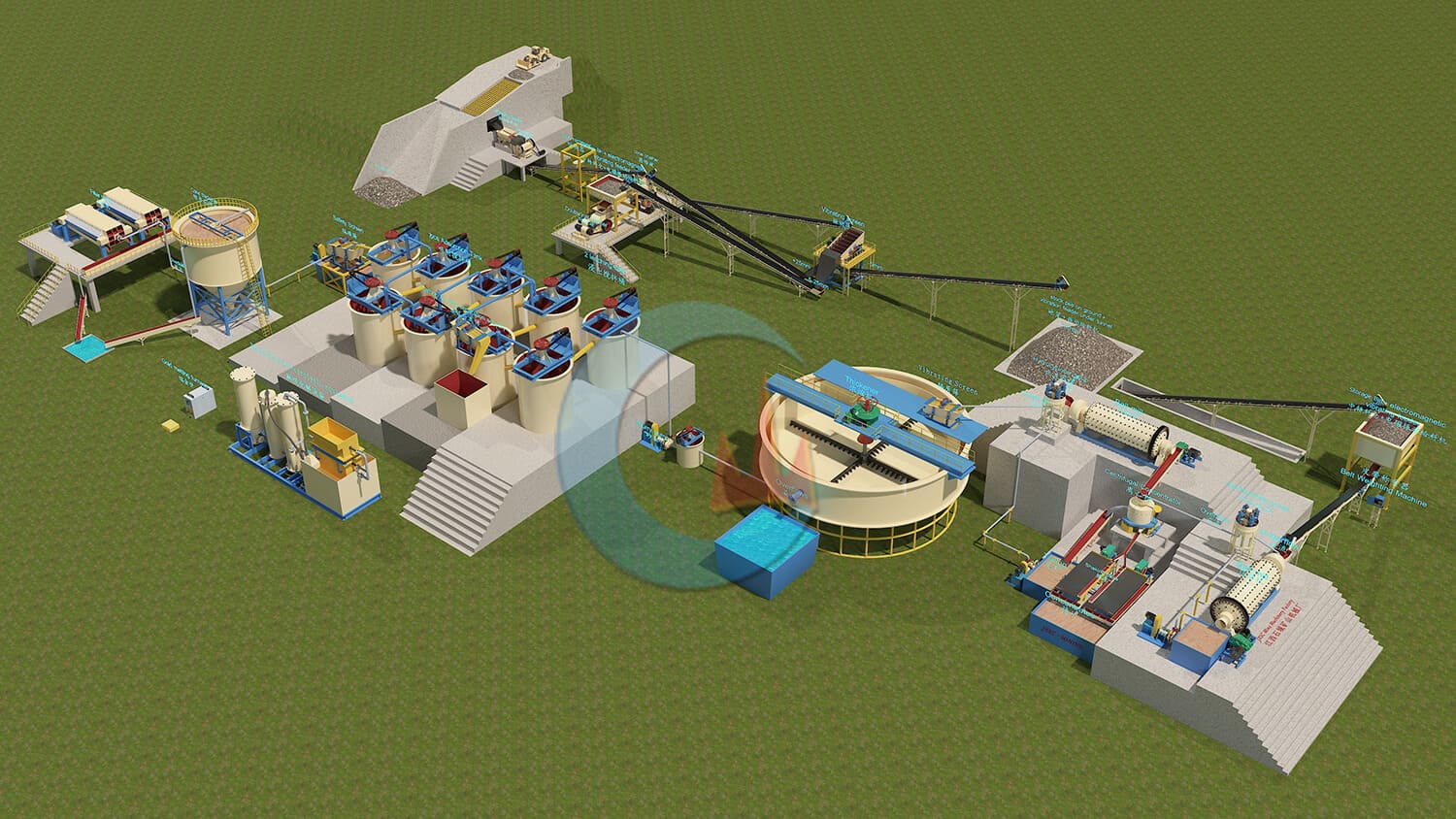

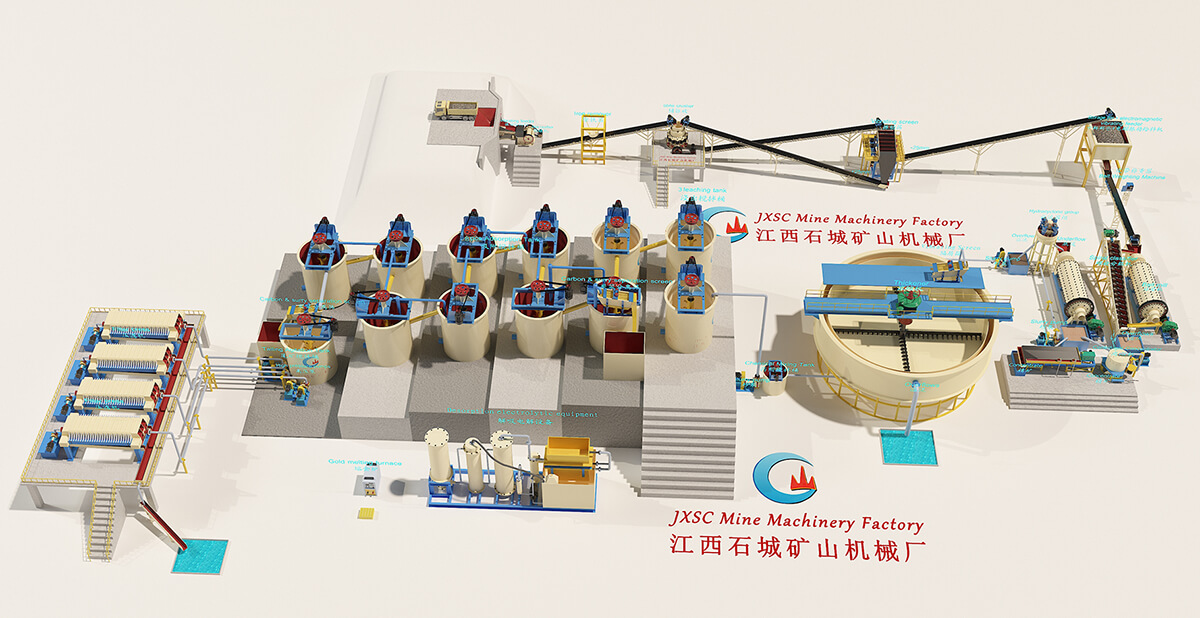

Compared with placer gold, rock gold ore has higher gold content and mining value, but the beneficiation process of rock gold ore is much more complicated than that of placer gold ore. Rock gold mines mostly use the flotation and cyanidation processes according to their characteristics.

Gold Ore Processing

- Carbon-in-pulp (CIP) consists of cyanide leaching and then absorption of gold from ore, which is considered a simple and cheap process. Using a CIP gold processing plant, pulp flows through tanks where sodium cyanide and oxygen help dissolve gold into solution. CIP plants are similar to Carbon-in-leach plants.

- Carbon-in-leach (CIL) is a process of cyanidation similar to that of CIP. The difference is that in a CIL plant, carbon is added to the leach tanks so that leaching and adsorption take place in the same tanks.

- Heap Leaching is a process that is used to treat the gold mine with low grade, cause it’s processed simply, easy operation, low energy consumption, investment saving, effective. Scale can be chosen, the maximum scale can be million tons /day.

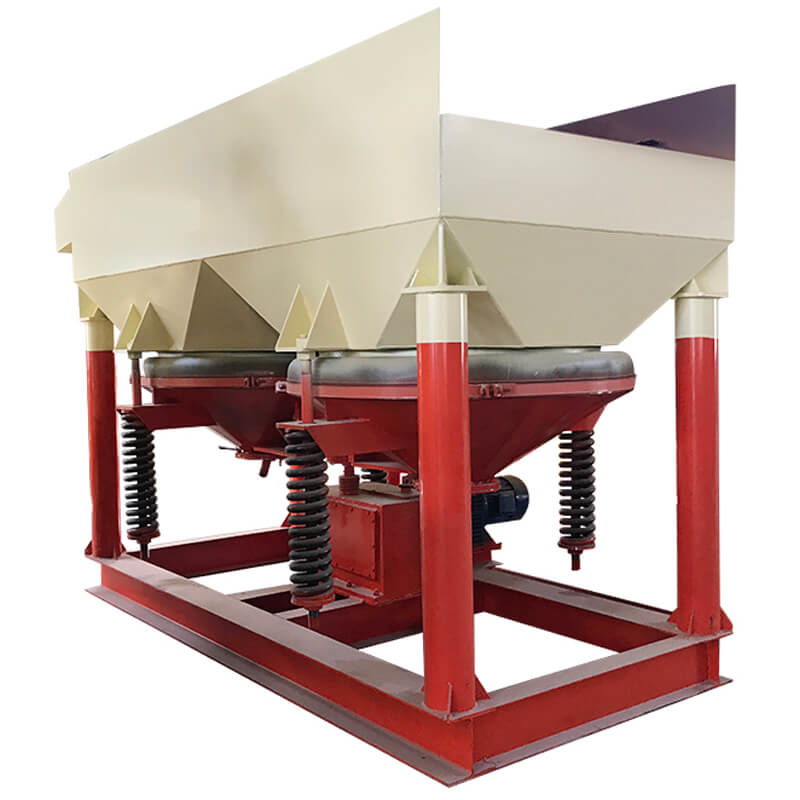

- Gravity separation is one of the commonly used methods for gold ore dressing. It uses different specific gravity of materials and different settling speeds in the medium for layered separation. Generally, in placer gold, when gold mostly exists in the form of monomer natural gold, it has a large density difference with gangue, which is effective and economical for gravity separation.

- The flotation process is commonly used in dealing with highly floatable sulfide minerals containing gold ore, and it’s widely used to process the rock gold. The gold flotation process cost low and can maximum enrich gold to the sulfide mineral.