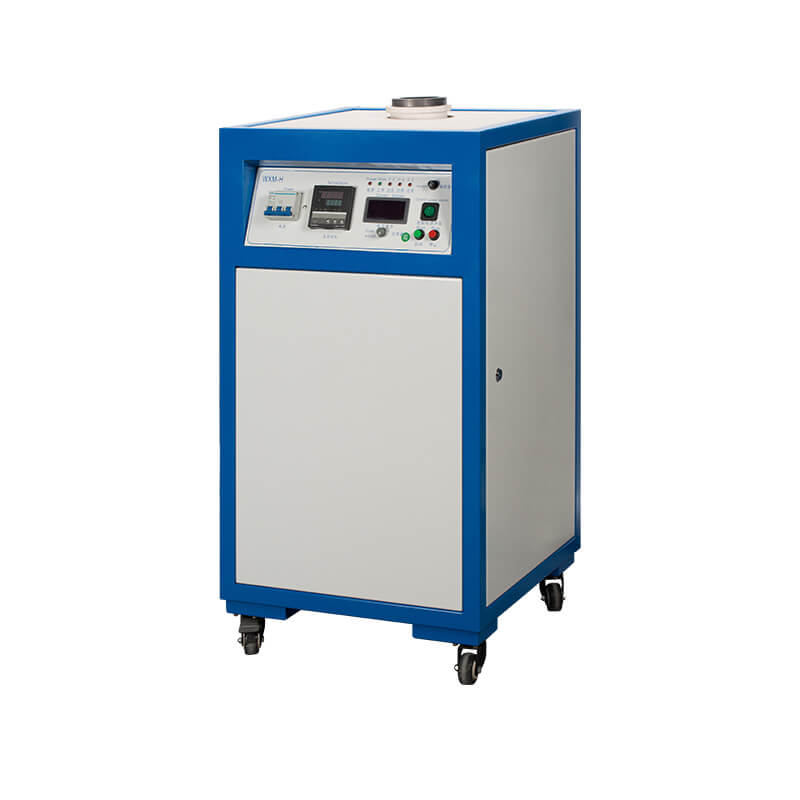

Small Cabinet Induction Melting Furnace

Frequency: 50/60HZ

Voltage: 220/380V

Capacity: 1-8kg

Melting Speed: 3-5mins

Procession Material: Gold, silver, copper, beryllium, and other non-ferrous metal

Small Cabinet Induction Melting Furnace Overview

A small cabinet induction melting furnace is a piece of equipment used to melt metal or other conductive materials. It adopts the principle of induction heating and generates an alternating magnetic field in the material through an induction coil so that the material generates an induced current, which makes the material self-heat and melt rapidly. Such furnaces are typically used for small-batch metal melting, alloy preparation, melt infiltration, and other applications.

Compared with large-scale industrial melting equipment, cabinet-type induction melting furnaces have smaller volumes and lower melting capacity and are suitable for laboratories, schools, jewelry processing, small production lines, and other occasions requiring small batch melting. Due to its high efficiency, rapidity, and environmental protection, small cabinet induction melting furnaces have been widely used in some specific fields.

Our Small Cabinet Gold Melting Furnace Features

- The maximum furnace temperature can reach 1500-2500 degrees.

- High heating efficiency and low noise during operation.

- The frequency range is wide, from 1KHz to 30KHz, the melting volume can be considered comprehensively, and the induction coil and matching capacitor box can be designed according to specific requirements.

- The machine is easy to install and operate, professionally debugged before leaving the factory, no on-site debugging is required, and it can work with water and electricity.

Advantages

Small Cabinet Induction Melting Furnace Advantages

- Heating: the fastest heating is less than one second, and the heating rate can adjust control.

- Energy saving: more than 95% thermal efficiency, the perfect alternative to silicon, gas, B decision, coke, and electric stove.

- Small footprint: less than 1 square, lightweight for easy mobility.

- Machine installation, simple operation, without onsite commissioning, water power can be.

- The machine safety and reliability: over-current, phase, water shortages, over-voltage, short circuit, overheat protection, greatly improving the device can be made of.

- Electromagnetic stirring enables more uniform melt helps scum, reduces impurities, and more light without casting solution or melt Shrinkage phenomenon.

- Mainly for metals: platinum, palladium, rhodium, gold, silver, copper, steel, aluminum, carbon, gold dust, sands, electrolytic mud, gold and silver powder, etc.

Structures & Working Principle

Small Cabinet Induction Melting Furnace Structure

The basic structure of the melting furnace includes the furnace body, burner, furnace bottom, furnace cover, and other components.

The furnace body is the main part of the melting furnace, usually made of high-temperature resistant materials, such as refractory bricks, castables, etc. The interior of the furnace body is usually divided into upper, middle, and lower areas, which are used for heating, melting, and collecting molten substances. Burners provide fuel and oxygen to maintain the high temperature in the furnace. The bottom of the furnace is the part used to collect and remove the molten material and usually has structures such as slag outlets and iron outlets. The furnace cover closes the furnace body to maintain a high temperature and prevent heat loss.

Small Cabinet Induction Melting Furnace Working Principle

Cabinet type gold smelting furnaceSiemens lGBT power all-solid-state inverter module technology, strong frequency induction heating device output current is through the induction coil generates a strong magnetic field. Under the action of the magnetic field is formed on the surface eddy current heating operation to rapidly heat the workpiece.

Technical Parameters

| Model | Rotor Spec (mm) | Feed Opening Size (mm) | Max Feed Edge(mm) | Capacity (t/h) | Motor Power(kW) | Weight(t) | Overall Dimension (L*W*H)mm |

| PF1007 | 1000*700 | 400*730 | 300 | 30-50 | 37-55 | 9.5 | 2400*1558*2660 |

| PF1010 | 1000*1050 | 400*1080 | 350 | 50-80 | 55-75 | 12.2 | 2400*2250*2620 |

| PF1210 | 1250*1050 | 400*1080 | 350 | 70-120 | 110-132 | 14.9 | 2690*2338*2890 |

| PF1214 | 1250*1400 | 400*1430 | 350 | 130-180 | 132-160 | 18.6 | 2690*2688*2890 |

| PF1310 | 1300*1050 | 490*1170 | 400 | 80-140 | 110-160 | 16.2 | 2780*2478*2855 |

| PF1315 | 1320*1500 | 860*1520 | 500 | 160-250 | 180-260 | 19.3 | 3096*3273*2667 |

| PF-1320 | 1320*2000 | 860*2030 | 500 | 160-350 | 300-375 | 28 | 3096×3560×3185 |

| PF-1520 | 1500*2000 | 1315*2040 | 700 | 300-500 | 400-450 | 42.8 | 3890×3560×3220 |