Portable High-Temperature Rapid Melting Furnace

Oscillation frequency: 30-100KHZ

Cooling water pressure: 0.2MPa

Inlet water temperature: <40℃

Input Voltage: 220/380V

Capacity: 0-5kg

Portable High-Temperature Rapid Melting Furnace Overview

The portable high-temperature rapid melting furnace is a kind of portable melting equipment mainly used to quickly melt metal or other materials. The portable melting furnace typically uses advanced heating technology capable of reaching high temperatures in a relatively short period to effectively melt the metal. And it is designed to be easily carried or moved from one location to another, making it suitable for various applications such as jewelry making, small-scale metal casting, laboratory use, and other situations where on-the-go or flexible melting capabilities are required.

Our Portable High-Temperature Rapid Melting Furnace Features

- Portability: The portable gold furnaces are designed to be lightweight and portable. It usually has a handle or structure for portability, allowing it to be easily carried or moved to a different job site.

- High-temperature capability: The portable high-temperature rapid melting furnace can quickly heat up to a relatively high temperature to meet the melting point requirements of different metals. This high-temperature capability makes it useful in jewelry making, laboratory research, small-scale metal casting, and more.

- Fast Melting: These furnaces can quickly heat metal to a melting point thanks to advanced heating technology. This improves work efficiency and reduces waiting time.

- Safety features: Portable high-temperature rapid melting furnaces are usually designed with safety in mind, including anti-scald handles, thermal insulation, and proper ventilation design.

- Control system: These gold furnaces are usually equipped with a temperature control system to ensure that the temperature can be accurately controlled during the melting process to avoid overheating or undercooling.

- Application fields: Portable high-temperature rapid melting furnaces are widely used in jewelry manufacturing, laboratory research, scrap metal recycling, and other scenarios. They are suitable for small-batch smelting of metals such as precious metals such as gold, silver, and copper, as well as common non-ferrous metals such as aluminum and zinc.

Advantages

Portable High-Temperature Rapid Melting Furnace Advantages

- Light weight, small size, and movable.

- It is very convenient to install and operate.

- 24-hour uninterrupted melting capacity.

- Fast heating speed, constant temperature after heating, saving electricity and energy.

- Good heating and heat permeability, uniform temperature.

- Full protection: equipped with overvoltage, overcurrent, overheating, water shortage, and other alarm devices, and automatic control and protection.

- Using IGBT power devices and unique variable current control technology.

- The precious metals are smelted, purified, cast, and other processes in an instant mainly through the crucible container.

- Melting gold, silver, copper, steel, aluminum, tin, and other precious metals such as platinum, gold, silver, silver mud, copper, gold fine powder, sand, and other metals.

- The amount of metal melted in a single time is 1-5KG, and the melting time in a single time is 5-10 minutes.

- The maximum furnace temperature can reach 1000 degrees – 1700 degrees.

Structures & Working Principle

Portable High-Temperature Rapid Melting Furnace Structure

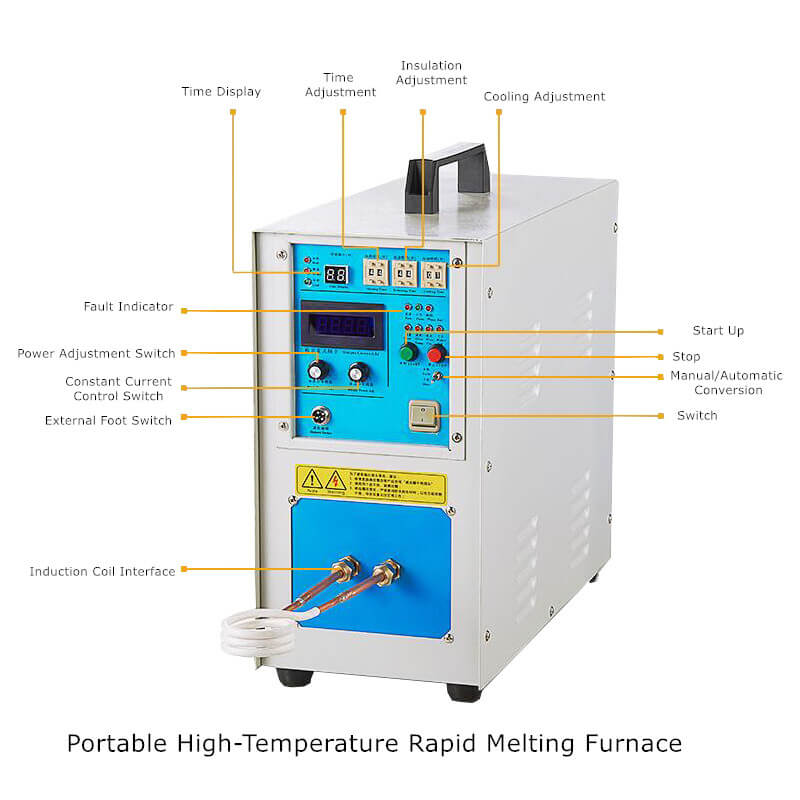

The portable high-temperature rapid melting furnaces include the following main components:

- Furnace body: The furnace body is the shell of a portable high-temperature rapid melting furnace, usually made of metal or special high-temperature-resistant materials. Furnace design usually considers thermal isolation and protection of operators from high temperatures.

- Heating elements:Portable high-temperature rapid melting furnaces use high-temperature heating elements, such as high-temperature resistance wires, electric heating plates, or high-frequency induction coils. These elements generate thermal energy that rapidly brings the metal sample to its melting point and melts it.

- Temperature control system: To precisely control melting temperature, this furnace is usually equipped with a temperature control system, which can set the required melting temperature according to needs and monitor the temperature change.

- Control panel: The control panel is the interface for operating the portable high-temperature rapid melting furnace. Operators can set the melting temperature from the control panel, start and stop the furnace, and monitor the melting process.

- Power supply: Stoves need power to power the heating elements. Portable stoves usually use batteries or power adapters for flexible use in different places.

- Crucible:A crucible is a container for metal samples or raw materials, usually made of high-temperature resistant materials such as ceramics or graphite. The crucible can withstand high temperatures and corrosion, ensuring the metal sample is not contaminated during the melting process.

- Cooling system: Portable high-temperature rapid melting furnaces usually generate a lot of heat and a cooling system is required to keep the temperature of the equipment stable. The cooling system is usually air-cooled or water-cooled to prevent the equipment from overheating.

Portable High-Temperature Rapid Melting Furnace Working Principle

The power supply adopts the all-solid-state Siemens IGBT frequency conversion module technology. A strong magnetic field is generated through the induction coil after the induction heating device outputs a strong variable frequency current. Under the action of the magnetic field, the heated working surface forms a vortex current, thereby rapidly heating the workpiece.

Technical Parameters

| Model | JXSC-GP15 | JXSC-GP25 |

| Max Input Power | 15kw | 25KW |

| Input Current | 33A | 43A |

| Input Voltage | Single phase 220V 50/60HZ | 3 phase 220V/380V 50/60HZ |

| Fluctuating frequency | 30-80KHZ | 20-40KHZ |

| Heating time | 1-99 seconds | 1-99 seconds |

| Load rate | 0.9 | 0.9 |

| Water temperature | ≤45℃ | ≤45℃ |

| water pressure | ≥0.15-0.2Mpa | ≥0.15-0.2Mpa |

| Water flow | ≥2L/Min | ≥6L/Min |

| Dimension | 225*450*480 | 650*250*600 |

| Weight | 25KG | 48KG |

| Metal Smelting Table | |||||||

| Model | Gold, Silver | Steel, Iron | Copper, Tin, Lead, Zinc | Aluminum, Silicon, Magnesium | Input Voltage | Input Power | Melting Time |

| JXSC-GP15 | 2kg | 200g | 2kg | 500g | 220v | 7kw | ≤ 10minutes |

| JXSC-GP25 | 5kg | 500g | 4kg | 1kg | 380v | 15kw | ≤ 10minutes |