Home » Equipment » Sand & Gravel Equipment » Fine Sand Recycling Equipment

Fine Sand Recycling Equipment

Fine Sand Recycling Equipment is an integrated system designed for efficient recovery and reprocessing of fine particles (typically 0.075-3mm) lost in traditional sand washing operations.

Capacity: 0-250 t/h

Application: Widely used in many fields, including construction aggregate production, concrete mixing plants, water conservancy and hydropower projects, mining, river dredging, harbor and waterway construction, and environmental protection treatment.

Fine Sand Recycling Equipment Overview

Fine sand recycling equipment is powerful, not only can it recover fine sand, but it also can desliming, dewatering, and de-mediation of slurry. The main role is to recover the lost fine sand, to solve the problems of unreasonable sand gradation and coarse fineness modulus, to improve the quality of sand, and to increase the revenue of enterprises.

Fine sand recycling equipment has a wide range of applications, the main use of the place is the sand and gravel quarry, all kinds of sand and gravel fine sand can be recovered, such as quartzite, river pebbles, cobblestone, basalt, limestone, and so on. Especially suitable for silica sand recycling, silica sand is also called quartz sand or silica, is quartz as the main mineral composition, particle size in 0.02-3.350mm refractory particles, so the fine sand recycling machine is also known as silica sand recycling machine, quartz sand recycling machine, fine sand recycling system and so on.

Applications

Large fine sand recycling equipment is mainly used to recycle and treat fine sand and mud produced in the process of sand and gravel production, to improve the utilization rate of resources and reduce environmental pollution. The fine sand recycling equipment is widely used in the following fields:

- Construction aggregate production: In the sand and gravel production line, it is used to recycle the fine sand produced in the production process and improve the comprehensive utilization rate of sand and gravel.

- Concrete mixing plant: Recycling fine sand and mud produced in the mixing process, reducing the waste of raw materials and improving the quality of concrete.

- Water conservancy and hydropower projects: In hydropower stations, reservoirs, dams, and other water conservancy and hydropower projects, it is used to recycle and treat the fine sand produced during the construction process, so as to meet the requirements of the project on the quality of sand and gravel.

- Mining: In the process of metal and non-metal mining, the fine sand in tailings is recovered to realize the secondary use of resources.

- River Dredging: In the process of river dredging, the fine sand produced in the dredging process is recovered and used for riverbed restoration or as materials for other projects.

- Harbor and waterway construction: In the process of harbor and waterway dredging and maintenance, fine sand is recovered and used for land reclamation or as materials for other projects.

- Environmental protection treatment: In construction waste treatment, industrial wastewater treatment, and other environmental protection projects, it recycles and treats fine granular materials to reduce environmental pollution.

Advantages

The main advantages of fine sand recycling equipment include improving concrete quality, environmental protection, and sustainable development, reducing production costs, and improving economic benefits. By recovering fine sand, the fine sand recycling machine improves the physical and mechanical properties of concrete, reduces the amount of cement, and at the same time meets the requirements of environmental protection, reduces production costs, and improves economic benefits.

Features

- Reduce the amount of fine sand loss, improve economic efficiency, and reduce the pollution of the environment at the same time.

- The vibrating screen adopts polyurethane screen mesh, which has a longer service life than other types of screen mesh, and is not easy to block the holes.

- The cyclone is lined with polyurethane, which improves the service life of the whole device and can successfully complete the work of slurry concentration and liquid clarification.

- The fine sand is fully recovered, which reduces the workload of the sedimentation tank and the cleaning cost of the sedimentation tank.

Structures & Working Principle

Fine Sand Recycling Equipment Structure

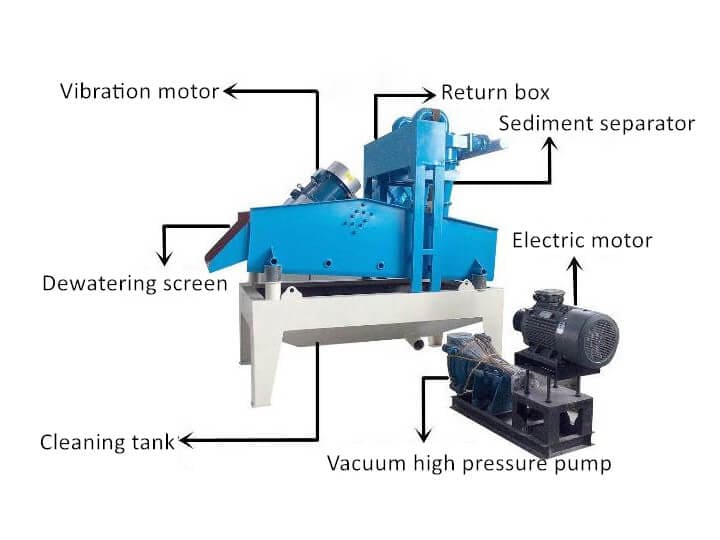

The structural composition of the fine sand recycling system mainly includes the following parts: motor, slurry pump, hydrocyclone, dewatering screen, cleaning tank, and return box.

The slurry pump mainly pumps the sand-water mixture in the cleaning tank to the cyclone, so that the sand-water mixture has a quick kinetic energy after entering the cyclone, thus providing a basis for centrifugal division of business in the cyclone. The slurry pump used in the fine sand recovery system is different from ordinary pumps or slurry pumps, which is mainly determined by the role it plays. A fine sand recovery system is used in the slurry pump, because the pump is a mixture of sand and water; therefore, it must have a certain wear-resistant, strike-resistant performance, otherwise, it will be very easy to damage, seriously affecting the use of the equipment.

The fine sand recovery system uses hydrocyclone, the cyclone is a fine sand recovery system for sediment separation, fine sand recovery of the core components, sand & water mixture in the role of the slurry pump was, speed transport to the cyclone, from the outer wall of the cyclone into the cyclone, by the cyclone inner wall of the role of the inner wall of the cyclone along the cyclone to do the speed of the screw war movement, the formation of a strong vortex, so that the sand and water in the process of rotating centrifugal grading, the more The fine sand particles quickly gathered to the center part, finally discharged from the bottom of the sedimentation nozzle, while part of the fine sand powder and soil is mixed with water, discharged from the upper overflow port.

The vibrating screen is mainly used to further dewater the fine sand recovered by the cyclone, so as to make the fine sand with lower water content and improve the quality of sand and gravel materials. The vibrating screen adopted by Maxon Heavy Industry’s fine sand recycling system is made of polyurethane material, which has the advantages of excellent abrasion-resistant and impact-resistant performance, and it is the ideal component for fine sand recycling device production, which can better guarantee the performance of the whole equipment.

Fine Sand Recycling Equipment Working Principle

Pump slurry sand-water mixture transported to the mud and sand high-pressure separator, centrifugal grading concentration of tail sand through the sedimentation nozzle provided to the dewatering screen, dewatering by the dewatering screen, tail sand and water effectively separated, a small amount of tail sand, mud, etc. through the return box and then back to the cleaning tank, cleaning tank liquid level is too high, discharged through the discharge port. Dewatering screen recycling material weight concentration of 70%-85%. Adjusting the fineness modulus can be realized by changing the pump speed, changing the slurry concentration, adjusting the overflow water volume, and replacing the slurry outlet. Thus, three functions of cleaning, dewatering, and grading are accomplished.

Technical Parameters

| Model | Dewatering Screen | Motor Power | Hydrocyclone | Slurry Pump | Power of Slurry Pump (kW) | Capacity (t/h) |

| DN1224 | 1200*2400 | 2.2kW *2 | Ф250*2 | 4/3AH | 15kW | 30-50 |

| DN1530 | 1500*3000 | 3kW *2 | Ф300*2 | 4/3AH*2 | 11kW*2 | 50-80 |

| DN1840 | 1800*4000 | 5.5kW *2 | Ф350*2 | 4/3AH*2 | 15kW*2 | 80-120 |

| DN2045 | 2000*4500 | 11kW *2 | Ф500*2 | 6/4AH*2 | 30kW*2 | 120-150 |

| DN2245 | 2200*4500 | 15kW *2 | Ф500*3 | 6/4AH*2 | 30kW*2 | 150-200 |

| DN2445 | 2400*4500 | 18.5kW *2 | Ф500*4 | 6/4AH*2 | 37kW*2 | 200-250 |