Electrostatic Separators

Arc plate electrostatic separator

It is suitable for the separation and selection of manganese ore, ilmenite, high tin tungsten ore, rutile, garnet, tantalum-niobium ore, chromite, rare earth ore, monazite, zircon, conductive and non-conductive minerals.

Capacity: 1-3 t/h

Feeding Size: 0-3 mm

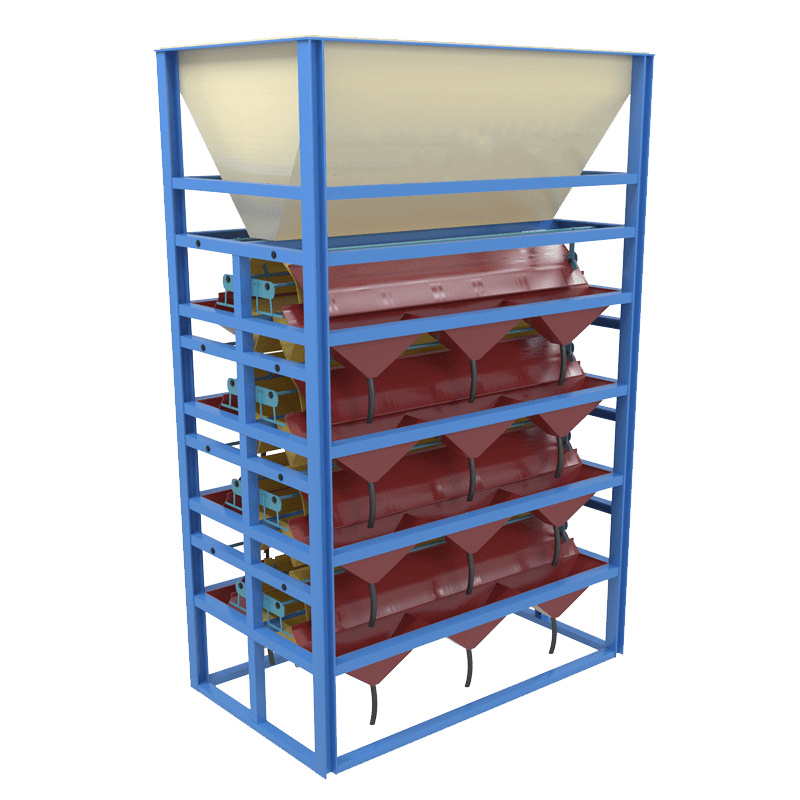

Roller electrostatic separator

It is widely used to separate titanium, zircon sand, rutile, monazite, iron, tungsten, tantalum-niobium, tin, gold, and other rare metal ores. The separation particle size is 0.1~2 mm and the surface temperature is less than 1%.

Capacity: 1-2 t/h

Feeding Size: 0-2 mm

Roller Electrostatic Separators

Electrostatic Separators Overview

The electrostatic separator uses the principle of difference in conductivity of different substances to separate various substances through the electric field generated by the electric field, thereby achieving the separation of different substances. It is widely used in mining, the chemical industry, building materials, metallurgy, medicine, and other industries.

Electrostatic Separator Application

The separation of non-ferrous metal and black metal, such as iron ore, zircon, cassiterite(tin), ilmenite, rutile, primary limonite, beach placer, manganese ore, titanium, tantalum-niobium, monazite and primary retiles, the separation of impurity mineral which associated with feldspar and quartz.

Common Electrostatic Separators Classifications

1. According to the method of particle charging, electrostatic separators are divided into:

- Conductive Charging Electrostatic Separators

- Triboelectric Separators

- Dielectric Separators

- Thermoelectric Adhesion Separators

2. According to the characteristics of the electric field, electrostatic separators are divided into:

- Electrostatic Field Separators

- Corona Field Separators

- Composite Field Separators

3. According to the structural form of the equipment, electrostatic separators are divided into:

- Drum Electrostatic Separators

- Chamber Electrostatic Separators

- Free-Fall Electrostatic Separators

- Chute Electrostatic Separators

- Belt Electrostatic Separators

- Disc Electrostatic Separators

- Shaking Table Electrostatic Separators

- Cyclone Electrostatic Separators

4. According to the size of the particles being separated or treated, electrostatic separators are divided into:

- Coarse Particle Electrostatic Separators

- Medium Particle Electrostatic Separators

- Fine Particle Electrostatic Separators

The most commonly adopted classification method combines structural characteristics with other properties, such as drum high-voltage electrostatic separators, cyclone fine particle electrostatic separators, and free-fall electrostatic separators, to differentiate them from other types of electrostatic separators. The most widely used type is the drum electrostatic separator, followed by the free-fall and sieve plate electrostatic separators. Other forms are used less frequently.

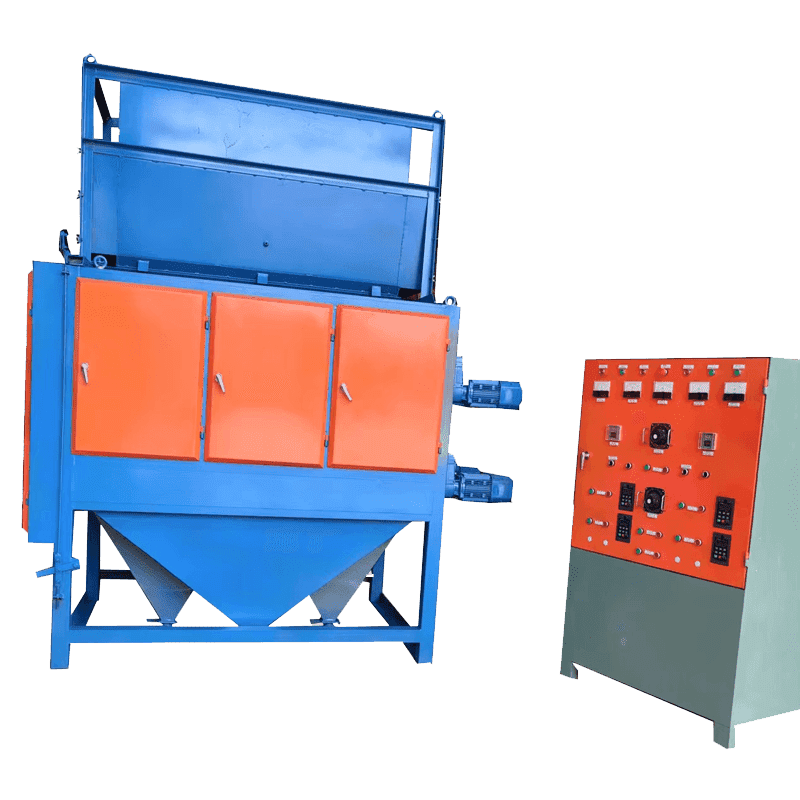

ARC Plate Electrostatic Separator

Some common types of electrostatic separators for mineral processing equipment

- Double-roller electrostatic separator:It is mainly used for the separation of scheelite and cassiterite, and rare metals. Its separation effect and separation index are relatively good.

- High-voltage electrostatic separator:It is used for separation of scheelite and cassiterite, tantalum and niobium ore, etc. The effect is very good.

- Drum-type electrostatic separator: It is mainly used for the separation of ilmenite, scheelite and cassiterite, and other heavy sand minerals. The working voltage is continuously adjustable from 0 to 60 kV.

- Multi-roller high-voltage electrostatic separator:It’s manily used for iron ore beneficiation.

- Slide plate type electrostatic separator:It is mainly used to separate small amounts of conductive minerals from a large amount of non-conductive products.

JXSC supplies electrostatic separators including ARC plate type electrostatic separators, roller electrostatic separators, etc.,

Advantages

Electrostatic separation can separate minerals with similar physical characteristics, such as size, shape, density, or color, but different electrical properties. This makes it useful for separating minerals that are difficult to distinguish by other methods, such as zircon, rutile, ilmenite, monazite, or cassiterite. Another advantage of electrostatic separation is that it can process dry materials, which reduces the water consumption and environmental impact of the operation. Moreover, electrostatic separation can be applied to a wide range of particle sizes, from microns to millimeters, and can handle high capacities and throughputs.

The advantages of electrostatic separators are large ore processing capacity, good separation effect, low cost, and high degree of automation.

ARC plate-type electrostatic separator advantages

- Good Separation Effect

- The arc plate electrostatic separator adopts a curved arc device, which can exert higher pressure on the ore, making the ore separation more thorough, and effectively improving the efficiency and quality of ore dressing.

- Low maintenance cost

- The arc plate electrostatic separator is simple to manufacture and does not have too many maintenance parts, so the maintenance cost is relatively low.

- Versatility

- Arc plate electrostatic separator can be used to separate particles according to their size and impurity level and to improve the grade and has a wider range of applications.

- Simpler operation

- The arc plate electric separator adopts an intuitive and simple operation method. The entire separation process can be completed by just pushing the ore into the equipment with an excavator.

Roller electrostatic separator advantages

- Efficiency

Effective at separating fine particles due to the strong electric field around the roller.

- Versatility

Can be used for a wide range of materials with different electrical properties.

- Continuous Operation

Suitable for large-scale, continuous processing operations.

Structures & Working Principle

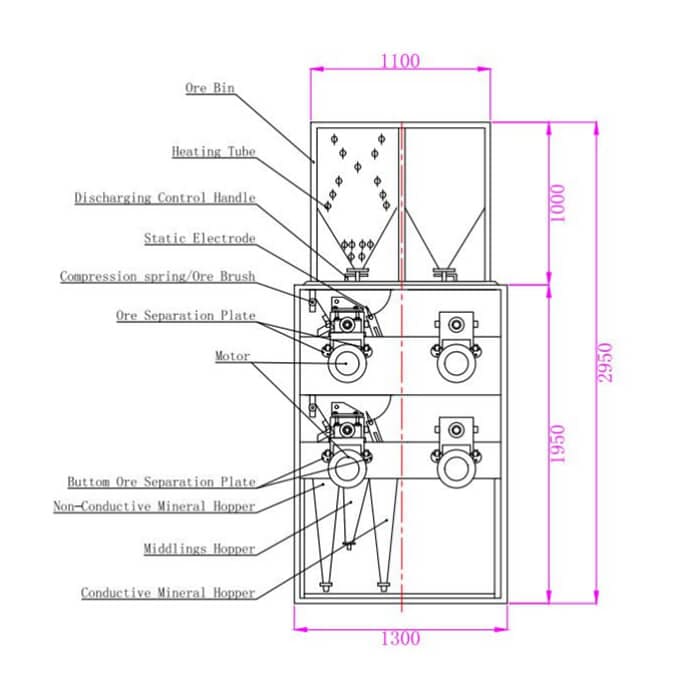

ARC Plate Electrostatic Separator Structure

Arc plate electrostatic separators comprise a feeding system, an electric field system, a consumables collection system, and a high-voltage DC power supply.

- The feeding system consists of a hopper, a vibrator, and a feeding mechanism, and is mainly responsible for spraying the raw materials into the electric field system;

- The electric field system consists of arc plates and brackets, and is mainly responsible for generating a high-voltage DC field;

- The consumables collection system is to capture and collect the separated materials from under the arc plate into a designated collection box;

- The high-voltage DC power supply is the core component of the arc plate electrostatic separator, responsible for providing high-voltage power, controlling the strength of the electric field, and the separation effect.

Roller Electrostatic Separator Structure

This roller electrostatic separator is composed of three parts: the main machine, the high-voltage electrostatic generator, and heating. The main machine is composed of two upper and lower rollers, corona electrodes, static electrodes (deflection electrodes), brushes, and ore separation plates.

Electrostatic Separator Working Principle

An electrostatic separator is a device that uses electric field force to separate materials with different charges. Its working principle is as follows:

- Define electric field: An electrostatic field is generated inside the electrostatic separator, that is, a voltage is applied between two electrodes to form an electric field with positive and negative charges.

- Material transportation: The material to be processed is transported to the feed port of the electrostatic separator by the feeder.

- Feed electrostaticzation: After the material enters the electrostatic separator, it will also carry corresponding positive and negative charges due to the electrode’s charge.

- Use electric field force: Charged materials will be affected by electric field force in the electric field. Positively charged materials are attracted by the negative electrode, and negatively charged materials are attracted by the positive electrode. According to the characteristics of the material and the parameters of the electric field, this electric field force can separate the material into different components.

- Separation and collection: The material is separated under the action of the electric field force, and the separated materials will move along different tracks and finally be collected by the collection device.

The electrostatic separator can only separate charged substances and not affect uncharged substances. In the design of the electrostatic separator, it is necessary to reasonably select the electric field parameters and the shape and layout of the electrodes to ensure efficient substance separation.

Technical Parameters

ARC Plate Type Electrostatic Separator

| Model | BXJ-2A4-30 | BXJ-2A5-60 |

| Capacity (t/h) | 1-2 | 1-3 |

| Feeding Size (mm) | 0-3 | 0-3 |

| Feeding Speed (cm/s) | 10-15 | 10-15 |

| ARC-Plate Size (mm) | 1600 | 1600 |

| Power (W) | 125 | 125 |

| Operation Voltage (KV) | 0-60 | 0-60 |

| High Voltage Current (MA) | 0-10 | 0-10 |

| Machine Weight (KG) | 1688 | 2100 |

| Overall Size (m) | 2.1*1.6*2.3 | 2.1*1.6*2.5 |

Roller Electrostatic Separator

| Model | JXSC-1615 | JXSC-1815 | JXSC-2215 |

| Roller Size (mm) | 160*1500 | 180*1500 | 220*1500 |

| Feeding Size (mm) | 0-2 | 0-2 | 0-2 |

| Double Roller Capacity (t/h) | 1 | 1.5 | 2 |

| Four Roller Capacity (t/h) | 1.5 | 2 | 3 |

| Double Roller Power (kw) | 1.5 | 1.5 | 1.5 |

| Four Roller Power (kw) | 3 | 3 | 3 |