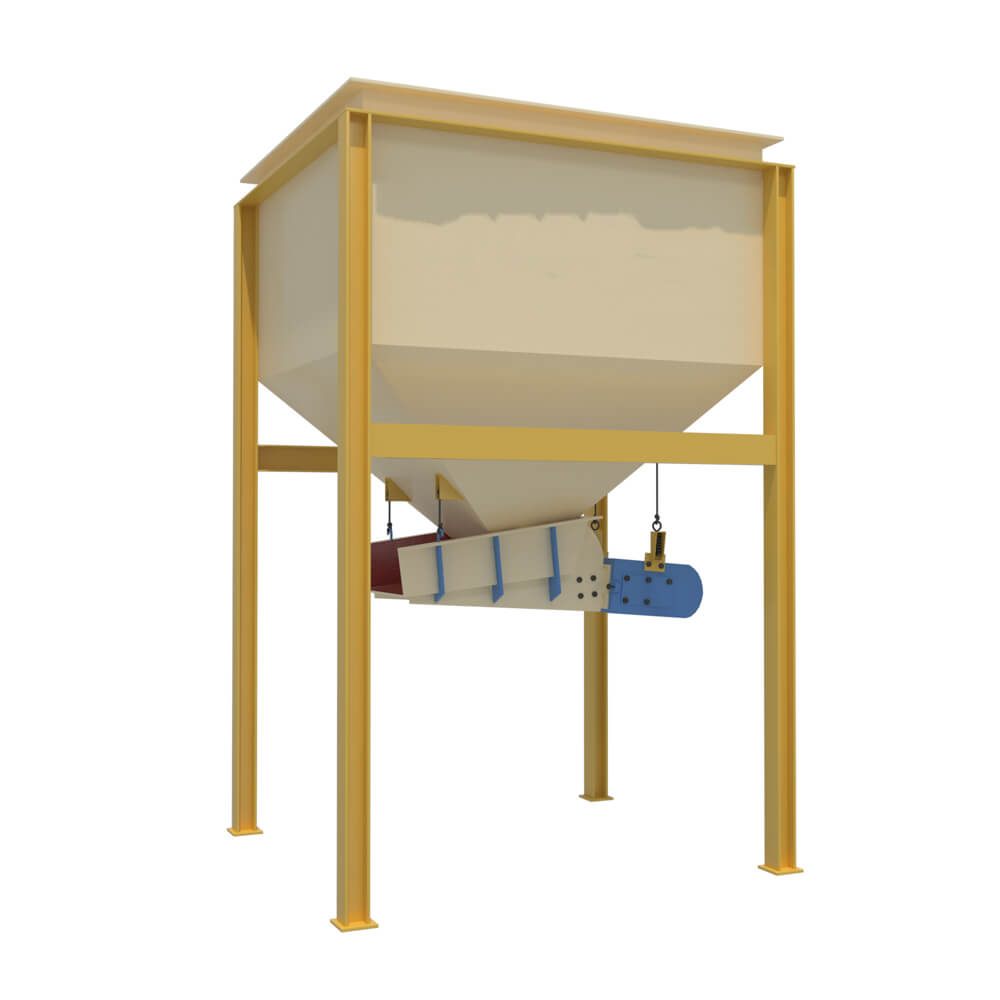

Electromagnetic Vibrating Feeder

Capacity: 5-150 T/H

Feeding Size: 50-200mm

Process Material: Gold, chrome, tin, coltan, diamond, tantalite, silica sand, etc.

Electromagnetic Vibrating Feeder Overview

An electromagnetic vibrating feeder is a new type of feeding equipment, widely used in mining, metallurgy, coal, building materials, chemical industry, electric power, grain, and other industries. Uniformly, continuously or quantitatively feeding bulk, granular, and powder materials from silos or other storage equipment to receiving equipment for automatic batching, quantitative packaging, and automatic control.

The electromagnetic vibrating feeder is a very useful device to handle feeding operations irrespective of the physical state like hot cold damp, granular dust, etc. The electromagnetic feeder also helps in taking the feeds to the next level of scalping, blending, packing, washing crushing cooling, etc. The efficiency of the electromagnetic vibrating feeder is such that it suits many operations.

Advantages

Electromagnetic Vibrating Feeder Advantages

- Small volume, lightweight, simple structure, convenient installation, convenient repair, and low operation cost.

- High efficiency and feeding capacity, high working frequency, and low electric consumption.

- Change the volume of flow at any time.

- Centralized control and automatic control of the production process.

- Small wear of feeding tank.

- The eccentric block is the source of vibration, low noise, less power consumption, good regulation performance, and no blanking phenomenon.

Structures & Working Principle

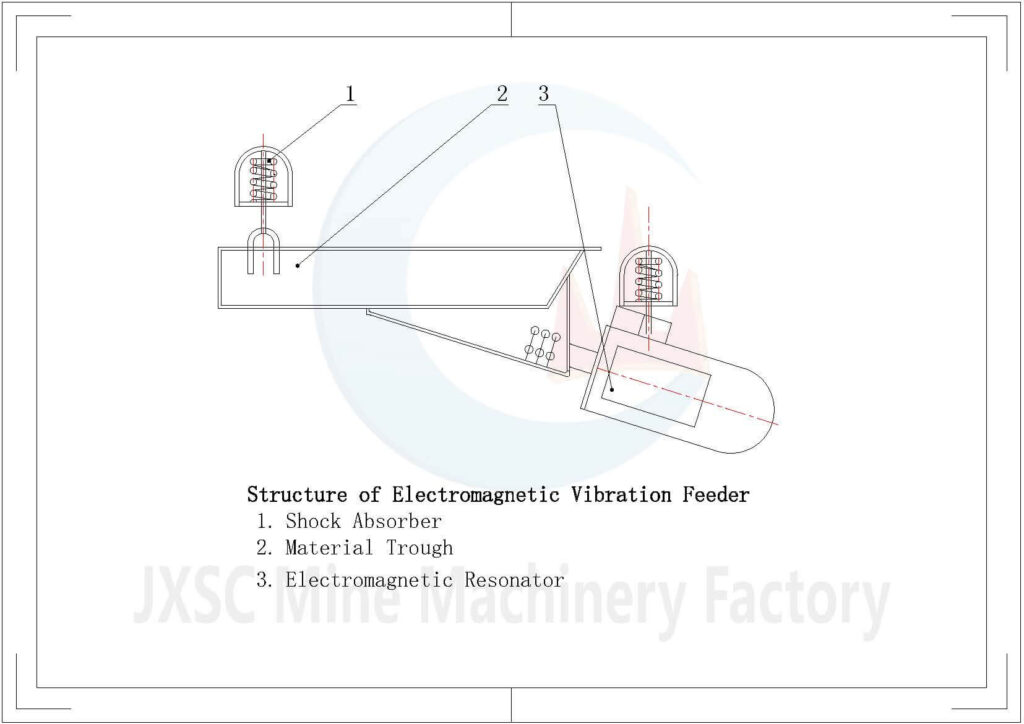

Electromagnetic Vibrating Feeder Structure

The main parts of an electromagnetic vibrating feeder include an absorber, feed tank, electromagnetic vibrator, and so on.

The electromagnetic vibrating feeder utilizes an electromagnetic vibrating device to drive minerals to reciprocate in the direction of the dip. When the vertical component of the accelerated speed of the feeder exceeds accelerated speed, minerals are tossed upward and leap forward in a parabolic fashion. It takes 1/5 second to finish the rising and falling. The chute vibrates for one time and subsequently, the minerals are tossed for one time. The chute vibrates at a frequency of 3000/minute. Correspondingly, minerals are tossed upward and have a leap forward. So minerals can continuously and uniformly move forward and feeding is achieved.

Technical Parameters

| Model | Discharge Chute Size L*W*H(mm) | Max Feeding Size (mm) | Capability (t/h) | Voltage(V) | Motor Power (kW) | Weight(kg) | Overall Dimensions L*W*H (mm) |

| GZ1 | 600*200*100 | 50 | 5-10 | 220 | 0.06 | 80 | 910*376*485 |

| GZ2 | 800*300*120 | 50 | 10-20 | 220 | 0.15 | 165.5 | 1175*608*600 |

| GZ3 | 900*400*150 | 75 | 20-30 | 220 | 0.2 | 223 | 1325*578*675 |

| GZ4 | 1100*500*200 | 100 | 30-50 | 220 | 0.45 | 462 | 1616*762*814 |

| GZ5 | 1200*700*250 | 150 | 50-100 | 220 | 0.65 | 656 | 1815*840*980 |

| GZ6 | 1600*900*250 | 200 | 100-150 | 380 | 1.5 | 1252 | 2410*1092*1500 |