Dual Vibration Motor Feeder

Capacity: 30-300 t/h

Feeding Size: 0-550 mm

Motor Power: 3-6 kW

Installation Slope: 10°

Dual Vibration Motor Feeder Overview

The motor vibrating feeder is a feeding equipment with a vibrating motor as the vibration source. Its vibrator composes two eccentric shafts at specific positions meshed and gears. During assembly, the two gears must be meshed according to the marks, and driven by the motor, causing the two eccentric shafts to rotate, thereby generating a huge combined linear excitation force, which forces the machine body to vibrate on the support spring. The material uses this vibration to slide and throw on the trough, moving the material forward and achieving the purpose of feeding.

The dual vibration motor is a commonly used vibration mechanical equipment. Dual motors drive it. The motors drive the vibrator to generate vibration force, thereby realizing the screening, transportation, and discharge of materials through the transmission of a synchronous belt and synchronous wheel.

The dual vibration motor feeder is also called the dual vibration motor feeding machine, or double vibration motor feeder. It can feed lumpy and granular materials from the storage bin to the material-receiving device evenly, regularly, and continuously in the production line. It can continuously and evenly feed the crushing machinery, and coarsely screen the materials, in the sand and gravel production line. The dual vibration motor feeder is widely used in combined crushing and screening equipment in metallurgy, coal mines, mineral processing, building materials, chemicals, abrasives, and other industries.

The dual vibration motor feeder has many features including a simple structure and easy maintenance, easy operation and control. It can evenly feed materials, avoiding material accumulation and blockage. It has become a famous and popular feeding machine in various industries, especially for mineral processing.

Advantages

Dual Vibration Motor Feeder Advantages

- Dual Motor Configuration:Equipped with two vibration motors, this feeder ensures synchronized and balanced vibrations, enhancing stability and efficiency in material conveyance.

- Adjustable Vibration Intensity: Operators can regulate the intensity of vibrations, allowing for precise control over material flow rates and ensuring compatibility with a wide range of materials and processing requirements.

- Customizable Speed Control: The feeder offers variable speed control options, enabling operators to adjust the conveying speed according to specific production demands and material characteristics.

- Highly Versatile: With its ability to handle various materials, from fine powders to coarse aggregates, the dual-vibration motor feeder is suitable for diverse industries, including mining, construction, pharmaceuticals, and food processing.

- Low Maintenance Requirements: Engineered for reliability and durability, this feeder typically requires minimal maintenance, reducing downtime and operational costs over its lifespan.

- Ease of Integration:Compatible with various automation and control systems, the feeder can integrate into existing production lines, enhancing workflow efficiency and productivity.

Structures & Working Principle

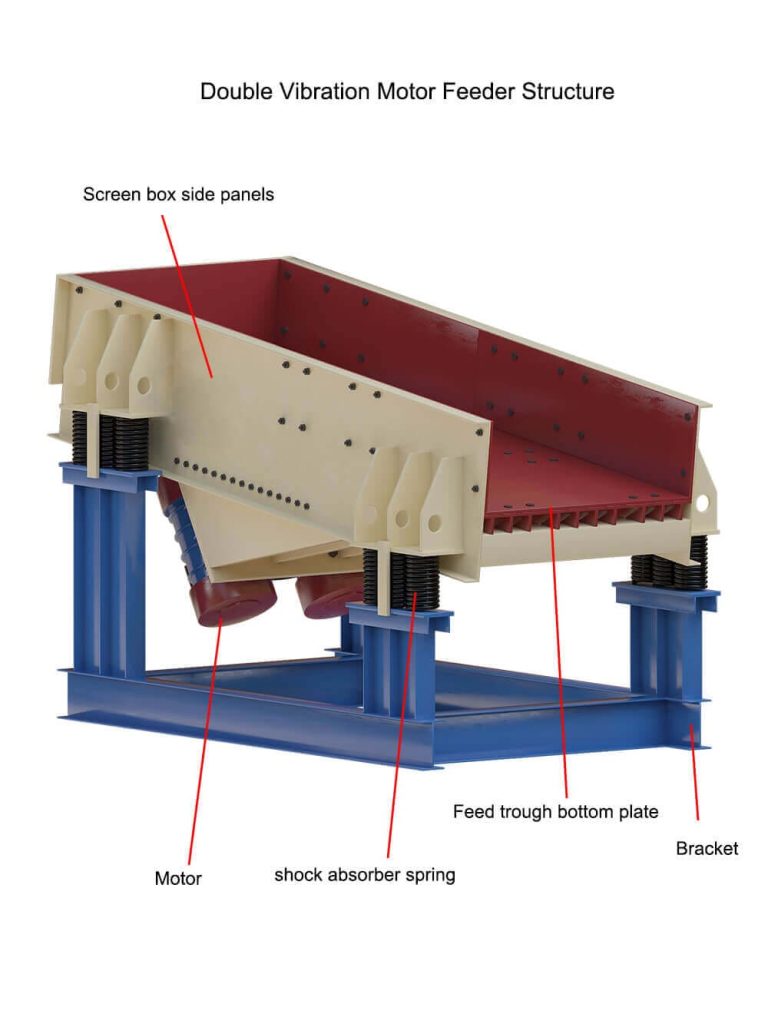

Dual Vibration Motor Feeder Structure

The dual-vibration motor feeder is mainly composed of a vibration box, feed hopper, bracket, and motor.

The vibration box is the core part of the vibrating feeder. Two motors drive two vibrators through couplings to achieve vibration. The movement in the vibrating box is violent, so you need to pay attention to safety.

Dual Vibration Motor Feeder Working Principle

Two vibrating motors rotate in the opposite direction. When the motor rotates, the eccentric blocks at both ends of the motors generate the exciting force, and the driving equipment makes reciprocating linear vibration in the inclined direction of the feeding tank. By adjusting the speed and intensity of the vibrations, the movement of the material can be controlled precisely. Ultimately, this controlled movement allows for the efficient discharge of material at the desired location.

Technical Parameters

| Model | Max Feeding Size (mm) | Capacity (t/h) | Motor Power (kw) | Installation Slope (°) | Double Amplitude (mm) | Weight (kg) | Overall Dimension L*W*H (mm) |

| GDN0724 | ≤400 | 30-80 | 2*1.5 | 10 | 45022 | 2320 | 2481*1130*990 |

| GDN1020 | ≤400 | 80-180 | 2*1.5 | 10 | 45024 | 2280 | 2080*1420*1210 |

| GDN1220 | ≤400 | 180-350 | 2*2.2 | 10 | 45024 | 2560 | 2080*1650*1210 |

| GDN0932 | ≤550 | 80-150 | 2*2.2 | 10 | 45024 | 3203 | 3298*1512*1195 |

| GDN0940 | ≤550 | 80-180 | 2*3 | 10 | 45024 | 3700 | 1100*1818*1134 |

| GDN1225 | ≤550 | 180-300 | 2*2.5 | 10 | 45024 | 3060 | 2926*1676*1475 |