Double-impeller Leaching Tank

Effective Capacity: 6-342 m³

Motor Power: 2.2-22 kW

Working Condition: The ore particle size below 200 mesh is greater than 90%; Slurry concentration≤ 45%.

Double-impeller Leaching Tank Overview

The double-impeller leaching tank is a specialized equipment used in the hydrometallurgical extraction process, particularly in the gold and silver leaching operations. It is mainly used in cyanide leaching of gold-producing and sewage treatment of cyanide factories. It is also used in metallurgy, chemical industry, and light industry. In the carbon slurry and cyanide processes, the leaching tank should be used with the carbon screen, carbon pulp, and other auxiliary equipment.

Compare the double impeller leaching tank with the ordinary mixing tank, it is designed with two impellers that provide superior mixing and agitation of the slurry. The impellers are typically arranged vertically, one above the other, ensuring that the mixing of pulp can be more uniform, in terms of energy consumption, the more saving energy. The impeller uses wrapping adhesive technology, long service life, and moral give into the gas use is for gas, air evenly.

Application

The double impeller leaching tank is suitable for gold leaching, adsorption, and other mixing operations where the specific gravity is small, the viscosity is low, the settling speed is slow, the ore particle size is -200 mesh accounting for more than 90%, and the slurry concentration is less than 45%. The double impeller cyanide leaching agitation tank equipment can be used for metallurgy, chemical industry, and light industry departments.

The double-impeller leaching tank is a highly effective piece of equipment for enhancing the leaching process in hydrometallurgy. Its design focuses on providing strong and uniform agitation, which helps in improving the dissolution rates of metals from ores, ultimately leading to higher recovery rates and more efficient extraction processes.

Advantages

Leaching Tank Advantages

- Wear-resistant rubber: The impeller of this leaching tank is lined with wear-resistant rubber, low rotation speed, and long service life.

- New impeller: Adopt two new impellers, the agitation tank features a large impeller diameter, low rotation speed, and small power consumption, which can reduce the wear of carbon.

- Leaching & adsorption rate: Moderate agitation intensity, and uniformly distributed in pulp concentration and fineness, which can improve the leaching rate of cyanidation and the adsorption rate of carbon.

- Multi-point aircharging system: The inflation system is a multi-point air supply. The air enters the tank through the transmission hollow shaft, the air enters the tank with uniform distribution and small bubbles.

- Low energy consumption:The ore flow moves smoothly, the ore slurry is evenly mixed, and the power consumption is low.

- Reasonable structure: This equipment is produced by introducing American technology,with a compact structure and easy to maintain.

Structures & Working Principle

Double-impeller Leaching Tank Structure

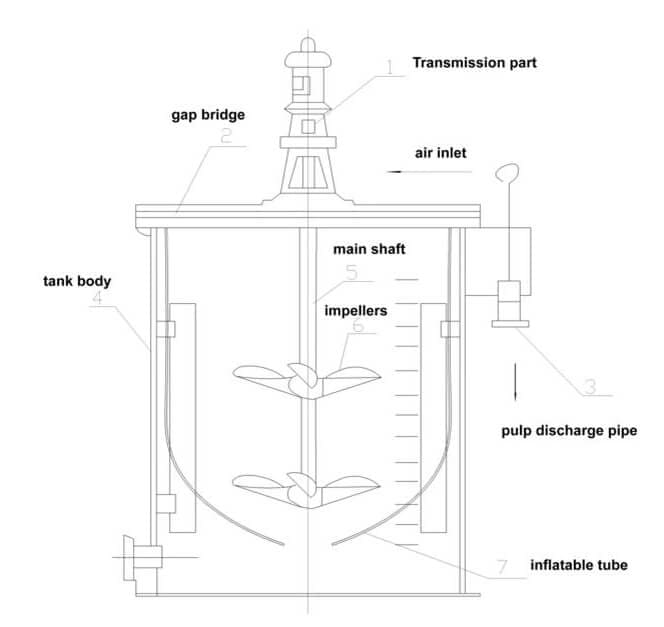

The double impeller leaching tank is composed of discharge value, transmission, reducer system, impeller shaft, impeller, tank body, discharging outlet, tank cover, etc.,

Double-impeller Leaching Tank Working Principle

With dual impellers rotating and agitating, ore pulps move downward and diffuse along with the damping plate. Air is fed in the tank from the lower end of the shaft and blended with ore pulps to form a uniform suspending mixed liquid.

Technical Parameters

| Model | Specifications Size of the Tank DxH(mm) | Effective Capacity (m3) | Rotary Speed of Impeller(r/min) | Diameter of Impeller (mm) | Diameter of Feeding Pipe (mm) | Diameter of Discharging Pipe | Planet Cycloid Reducing Motor | Weight (kg) | ||

| Model | Speed Ratio | Motor Power (kW) | ||||||||

| Ⴔ2.5×2.5 | 2500×2500 | 6 | 65 | 800 | 2-Ⴔ133 | 2-Ⴔ133 | XLD2.2-4-29 | 29 | 2.2 | 2800 |

| Ⴔ2.5×3.15 | 2500×3150 | 13 | 57 | 935 | 2-Ⴔ125 | 2-Ⴔ125 | XLD2.2-4-29 | 29 | 2.2 | 3120 |

| Ⴔ3×3.15 | 3000×3150 | 18.93 | 51 | 1130 | 2-Ⴔ150 | 2-Ⴔ150 | XLD4-5-35 | 35 | 4 | 5300 |

| Ⴔ3.15×3.55 | 3150×3550 | 24 | 43 | 1260 | 2-Ⴔ150 | 2-Ⴔ150 | XLD4-5-35 | 35 | 4 | 5488 |

| Ⴔ3.5×3.5 | 3500×3500 | 29 | 46 | 1310 | 2-Ⴔ150 | 2-Ⴔ150 | XLD5.5-5-29 | 29 | 5.5 | 7820 |

| Ⴔ3.55×4.0 | 3550×4000 | 35 | 36.3 | 1310 | 2-Ⴔ150 | 2-Ⴔ150 | XLD4-5-35 | 35 | 4 | 6646 |

| Ⴔ4.0×4.5 | 4000×4500 | 50 | 33.5 | 1500 | 2-Ⴔ150 | 2-Ⴔ150 | XLD7.5-7-43 | 43 | 7.5 | 8285 |

| Ⴔ4.5×5.0 | 4500×5000 | 71.67 | 33.5 | 1750 | 2-Ⴔ159×6 | 2-Ⴔ159×6 | XLD7.5-7-43 | 43 | 7.5 | 10800 |

| Ⴔ5.0×5.6 | 5000×5600 | 98 | 31 | 1900 | 2-Ⴔ159×8 | 2-Ⴔ159×8 | XLD11-8-47 | 47 | 11 | 13340 |

| Ⴔ5.5×6.0 | 5500×6000 | 112 | 31 | 2100 | 2-Ⴔ159×8 | 2-Ⴔ159×8 | XLD11-8-47 | 47 | 11 | 18745 |

| Ⴔ7.5×8.0 | 7500×8000 | 268.6 | 21 | 2900 | 2-Ⴔ159×8 | 2-Ⴔ159×8 | XLD22-10-47 | 47 | 22 | 32796 |

| Ⴔ8.0×8.5 | 8000×8500 | 342 | 16.4 | 3200 | 2-Ⴔ159×8 | 2-Ⴔ159×8 | XLD22-11-59 | 59 | 22 | 42467 |