Dewatering Equipment

JXSC has very strict production management and advanced production technology in dewatering equipment. We own advanced cutting, automatic welding, and boring machines, which make our dewatering machine of high quality and good appearance.

JXSC has been engaged in the production and sales of dewatering equipment since 1985. It is a professional manufacturer of crushers and beneficiation equipment in China. The types of dewatering machines include dewatering screens, rotary dryers, thickeners, plate & frame filter presses, disc vacuum filters, belt filter presses, and so on.

Dewatering Equipment for Sale

Basic Parameters of Equipment

| Dewatering Equipment | Capacity | Power | Others |

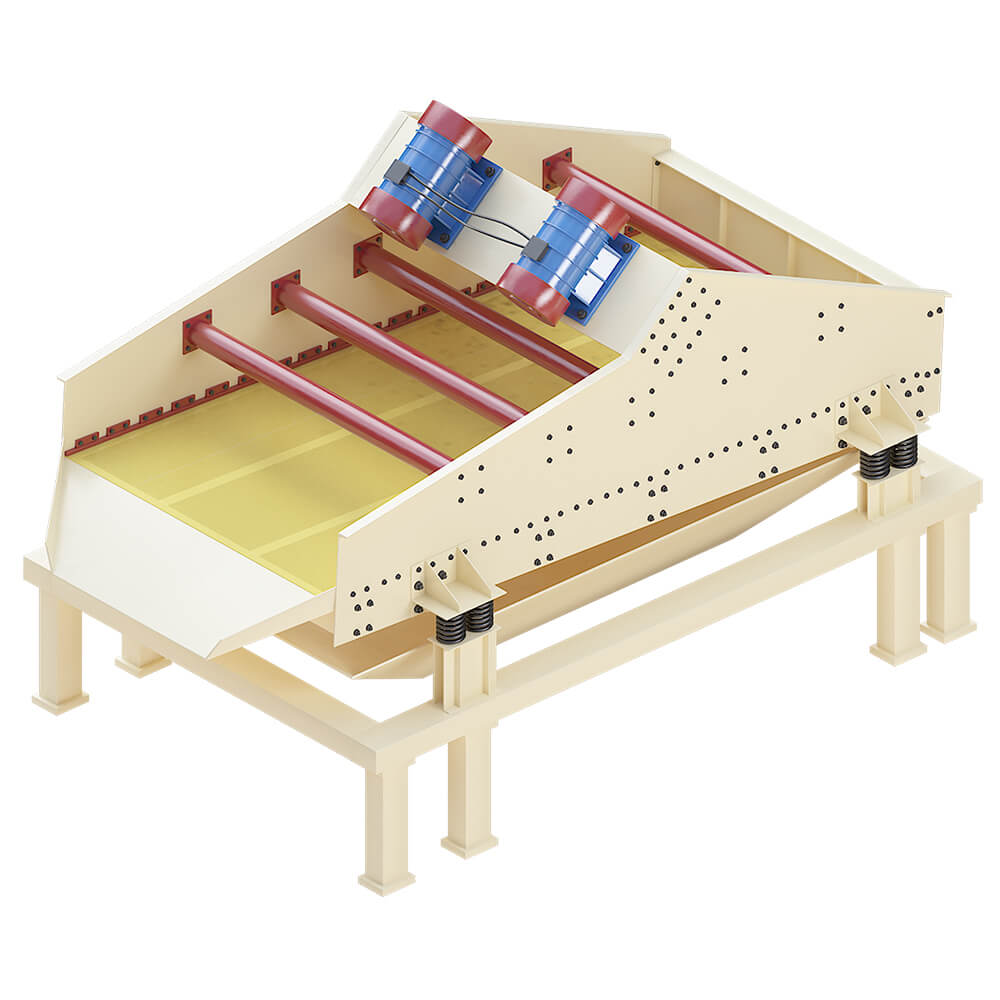

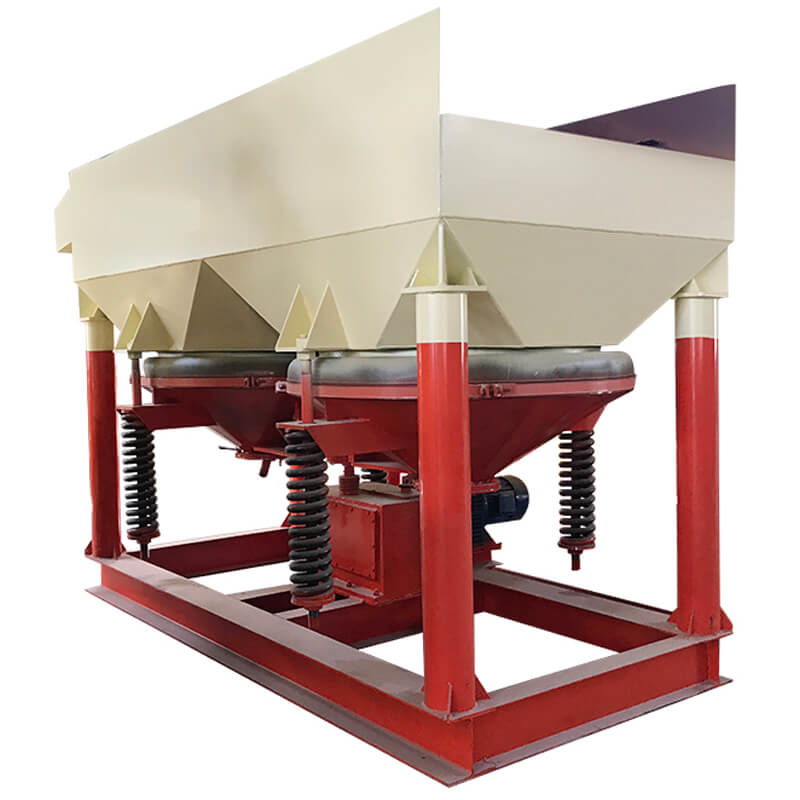

| Dewatering Screen | 10-250 T/H | 2.2-30 kW | Screening sieve hole size: 0.2-0.5mm |

| Rotary Dryer | 1.9-76 T/H | 7.5-160 kW | Procession Material: Gold, chrome, tin, coltan,diamond,tantalize, silica sand |

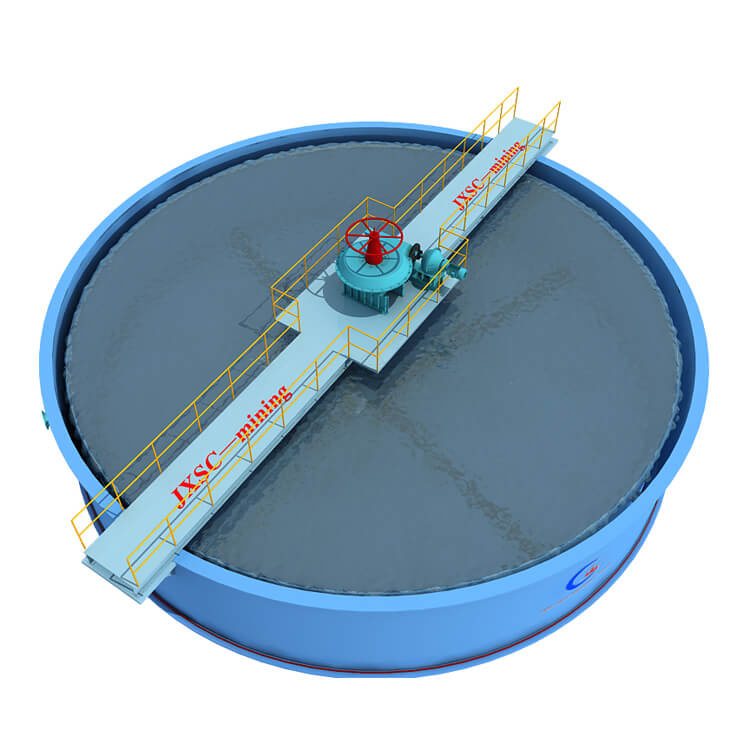

| Thickener | 1.3-1440 T/D | 1.1-11 kW | Feeding Size: 0-3 mm |

| Plate And Frame Filter Press | 0.24-7.96 m3 | 2.2-5.5 kW | Filter Areas: 20-500 ㎡ Filter Plates: 20-128 pcs |

| Disc Vacuum Filter | 0.85-1.2 t/h•㎡ | 2.2-15 kW | Filtering Area: 10-120 ㎡ |

| Belt Filter Press | 0.5-30 t/h | 0.75-7.5 kW | Slurry feed concentration: 3-8% Output concentration: 25-40% |

JXSC Mineral

Mineral processing equipment and solutions

Dehydration

Saving Cost

-

Application: Flotation process, tailings treatment, ore drying, etc.

-

Function: Reduce the volume of slurry, improve product quality, and reduce transportation and subsequent processing costs.

-

Dehydration Methods: Centrifugal dehydration, filter press dehydration, vacuum dehydration, filtration dehydration, hot air flow dehydration, etc.

Popular