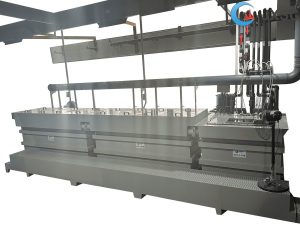

Cyclone(Swirl) Electrolysis Copper Recovery Equipment

Waste Liquid Treatment Capacity: 0-200 Tons/Month

Copper Production Capacity: 0-4 Tons/Month

Electricity Load: 20-80 kW

Cyclone electrolysis technology is a wet refining and purification of metals, the current application areas of this technology include: copper metal refining, widely used in various smelters.

The Cyclone Electrolytic Copper Recovery Plant is specially designed for the efficient recovery and refining of copper scrap.

Cyclone(Swirl) Electrolysis Copper Recovery Equipment Overview

The cyclone/swirl electrolytic copper recovery equipment is specially designed for the efficient recovery and refining of copper scrap. Combining cyclone separation and electrolysis technology, the plant is capable of extracting high purity copper from copper scrap material in a short period of time and is widely used in metallurgical and metal recycling industries.

Cyclone Separation: After the waste is crushed and pulverized, it enters the cyclone. Utilizing centrifugal force, heavier copper particles are separated from lighter impurities (e.g. plastics, rubber, etc.), and copper substances are effectively extracted.

Electrolysis Technology: The separated copper particles enter into the electrolytic tank, where the copper ions are reduced to high-purity copper through electrolytic reaction, and the impurities remain in the electrolyte or are deposited as anode sludge, and the pure copper is further extracted.

Cyclone electrolysis technology is a wet refining and purification of metals, which is a new technology capable of selective electrolysis (electrowinning) of valuable metals, especially suitable for metallurgical industry to carry out selectiatve electrolysis (electrowinning) separation and purification of low-content solutions, solutions with complex compositions, as well as refining heavy metal ions in wastewer.

Advantages of cyclone/swirl electrolysis technology

- A wide range of applications can be applied to many industries.

- Wide adaptability of raw materials, the same equipment can process a variety of metals, and selective electrolytic deposition of metals;

- Flexible and diverse, can be targeted according to customer demand for process design;

- Portable, modular components, easy assembly, modular installation, small footprint, high space utilization;

- Thorough metal recovery sharing, ppm level metal recovery separation.

- Easily reduce the metal ions in your recovered solution to less than 1000 ppm, and make the valuable metals you need to recover into sheet or powder products (>99.96%);

- Closed circuit circulation of the solution, effectively recovering the acid in the solution, avoiding acid mist emission, safe and environmentally friendly.

- Higher current density and current efficiency;

- Simplified process flow, greatly reducing your operating costs and lowering your technical risk;

- Compared with the traditional electrolysis technology, using cyclone electrolysis technology can advance the cost recovery period at least 18 months to 36 months; improve product purity, improve profitability, realize quick profit, and have a higher return on capital.

Our Product/System Features

The cyclone electrolysis copper recovery machine avoids the traditional electrolytic process by a variety of factors (ion concentration, precipitation potential, concentration polarization, over potential, PH(value), the low concentration of solution for efficient, high purity electrolytic extraction, metal recovery can reach ppm level. Cathode copper can reach 99.99%. Solution closed-circuit circulation effectively prevents electrolytic exhaust from polluting the environment, modular and portable device, easy to expand or transfer, and easy to operate.

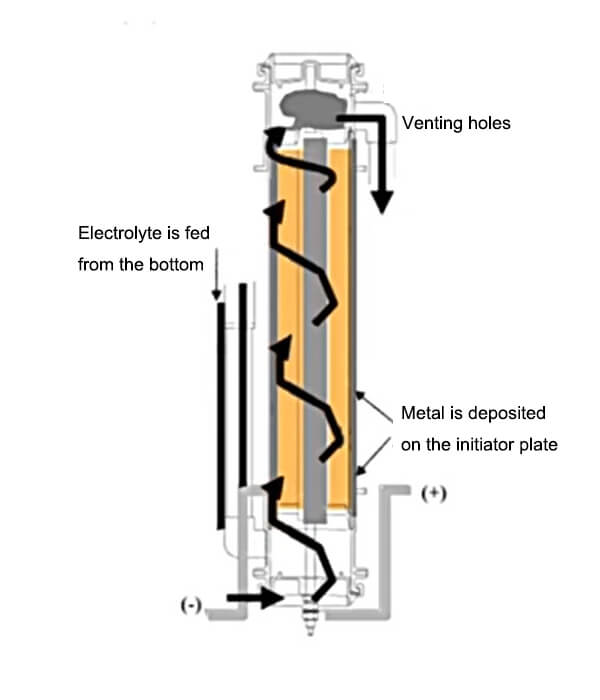

Structure/Working Principle

Cyclone Electrolysis Copper Recovery Equipment Structure/Process

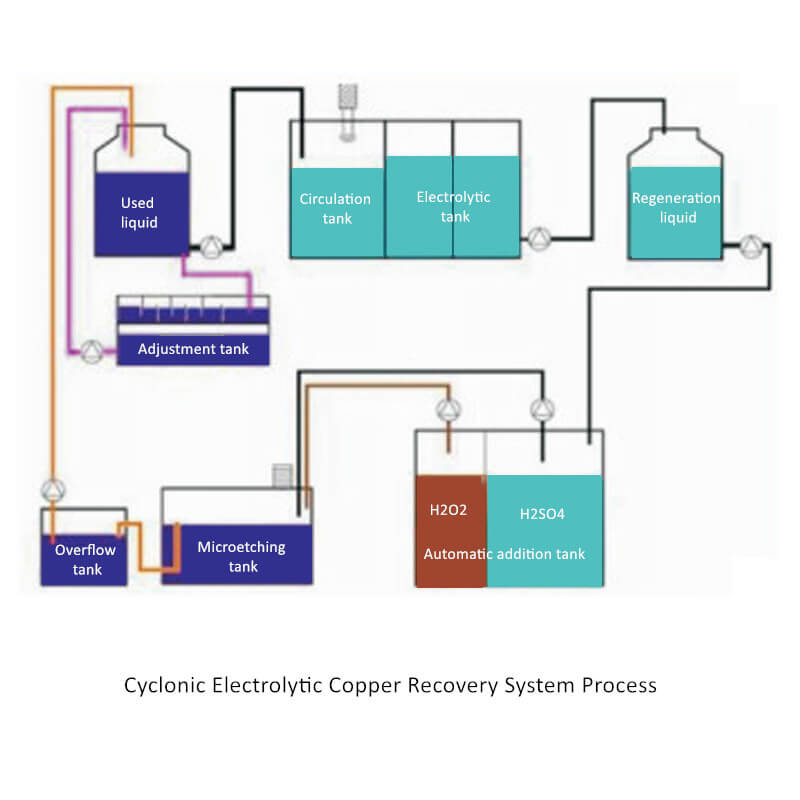

Cyclone electrolysis equipment is a comprehensive system integrating process equipment, electrical equipment, and control systems. The process is that the electrolytic solution is sent from the storage tank to the swirl electrolytic tank and arranged according to the design through the solution delivery pump, the solution is circulated inside the device system, and the valuable metal ions are separated from the electrolytic solution by selective electrolysis and adsorbed to the cathode plate. Barrel products are collected by a special product collection device, and powder products are automatically collected by a special powder collection system. The barrel-shaped product is further made into a plate body product through a subsequent supporting product processing device. The supporting intelligent power distribution device system and integrated control system that can operate at high current density and high efficiency adopts a redundant hardware system and all-digital software-type high-precision trigger adjustment controller, duplex hot backup, and anti-harmonic interference. , Anti-strong magnetic field interference, communicates with the master control PLC system to complete the intelligent control of electrolytic current. Combined with the patented technology of the automatic control system, it can realize the independent detection of flow, liquid level, temperature, etc. in the production process, and ensure the accuracy and reliability of large-scale production.

Cyclone Electrolysis Copper Recovery Equipment Working Principle

Cyclonic electrolytic copper extraction equipment uses two direct electrolysis methods, the hydrogen peroxide in the waste liquid is cracked by electrolysis first, and then into the electrolytic cell or cyclonic electrolytic tank. After electrolysis of copper by adding a small amount of agents, the micro etching solution can be effectively recovered and recycled.

Technical Parameters

| Model | Waste Liquid Treatment Capacity (Tons/Month) | Electricity Load (kW) | Copper Production Capacity (Tons/Month) | Occupied Area(m2) |

| YZ-XLDJ50 | 50 | 20-30 | 1.0 | 30-40 |

| YZ-XLDJ100 | 100 | 40-50 | 2.0 | 50-60 |

| YZ-XLDJ200 | 200 | 70-80 | 4.0 | 80-100 |