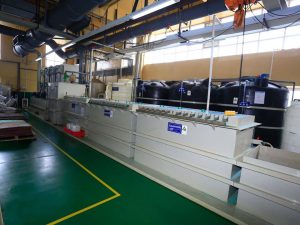

Copper Powder Recovery Equipment

Applicable Process: Deburring, Removing Copper Particles, Dry Film Pre-treatment, Solder Mask Pre-treatment, ENIG Pre-treatment, HASL Pre-treatment, and other positions that need to be filtered

Copper Powder Recovery Equipment Overview

The copper powder recovery equipment can recycle and treat the metallic dust pollution generated by the grinding and brushing process in PCB production, reduce the cost of wastewater treatment, save water and electricity, and eliminate the cost of cleaning clogged drains. The copper powder recycling equipment is suitable for the following occasions:

- Brushing of steel plates after pressing

- Brushing before drilling and PTH

- Brushing before image transfer

- Brushing after removing the film from the inner and outer laminates.

- Brushing before printing solder resist

- Brushing after tin spraying and soldering

- Brushing before nickel plating of gold fingers

- Wastewater recycling system for all kinds of grinding plants

The board milling process in the PCB industry generates a large amount of copper-containing dust and waste, which can be processed and reused through specialized recycling equipment. To save water in the board milling line, reduce wastewater treatment costs, and efficiently filter the copper powder into treasure, the copper powder recycling equipment in the board milling process usually requires efficient filtration, separation, and environmentally friendly treatment. Our copper powder recycling plant is really for you to realize, occupies a small area, and the filtered copper powder is not high water copper mud, to realize the semi-drying of copper powder, technology, and the effect are particularly good.

Copper Powder Recovery Equipment Use

- Realize the recycling of traffickable copper powder, turning waste into treasure with considerable benefits.

- If the copper powder generated in the process of PCB board grinding is not filtered and circulated directly back to the spray section, the filtering can prevent the clogging of nozzles or pipelines.

- It can prevent the copper powder from participating in the board surface grinding caused by brush roller wear and board surface unclean.

- It can prevent uneven grinding and excessive copper powder residue will cause hole plugging and anti-soldering section of the hidden danger of micro-short circuit.

- The use of copper powder recycling machines can realize the recycling of water, reduce industrial water standards, reduce environmental pollution and sewage treatment pressure, and direct cost savings.

Our Product/System Features

Automatic filter recovery machine, automatic operation, high filtration accuracy, stable and reliable performance, is to replace the traditional manual filter or use the abandoned type.

Filter material filter benefit selection, liquid from the filter inlet into, flow from top to bottom, through the filter element surface flow to the outlet when the filter surface.

When a certain amount of impurities are collected, the liquid containing a high concentration of impurities is discharged and the residual liquid can be recovered or discharged.

Working Principle/Process

Copper Powder Recovery Equipment Working Principle and Process

Automatic filter recovery machines and recoiling-type self-cleaning water filters are different, filter are not only used for water filtration, more widely used in solvent, acid lye, polymer, paint, and other viscous material self-cleaning filtration, higher efficiency, accuracy range of 5-1500 micron, can deal with a viscosity up to 800,000 cm of liquid, Applied in water treatment, petrochemical, metallurgy, electric power, fine chemical industry, paint, ink, paper, food and beverage, pharmaceutical, metal processing, and other industries.

Technical Parameters

| Outer Size(L*W*H) | 1300mm * 800mm * 1600mm |

| Filter Auxiliary Tank(L*W*H) | 300mm * 600mm * 500mm x 1set |

| Stainless Steel Filter Tank | Φ500 * 700L x 1set |

| Fresh Water Pump | 3HP, flow rate 120 L/Min x 1set |

| Pressure Switch | YK0.2 x 1pc |

| Power Supply | 3-phase 380V AC, 2.5KW |

| Water Level Control | Alarm when the liquid level is low (the pump will stop automatically after the delayed pumping of water back to the grinding plate). |