Copper Extraction Equipment From Brownification Waste Liquid

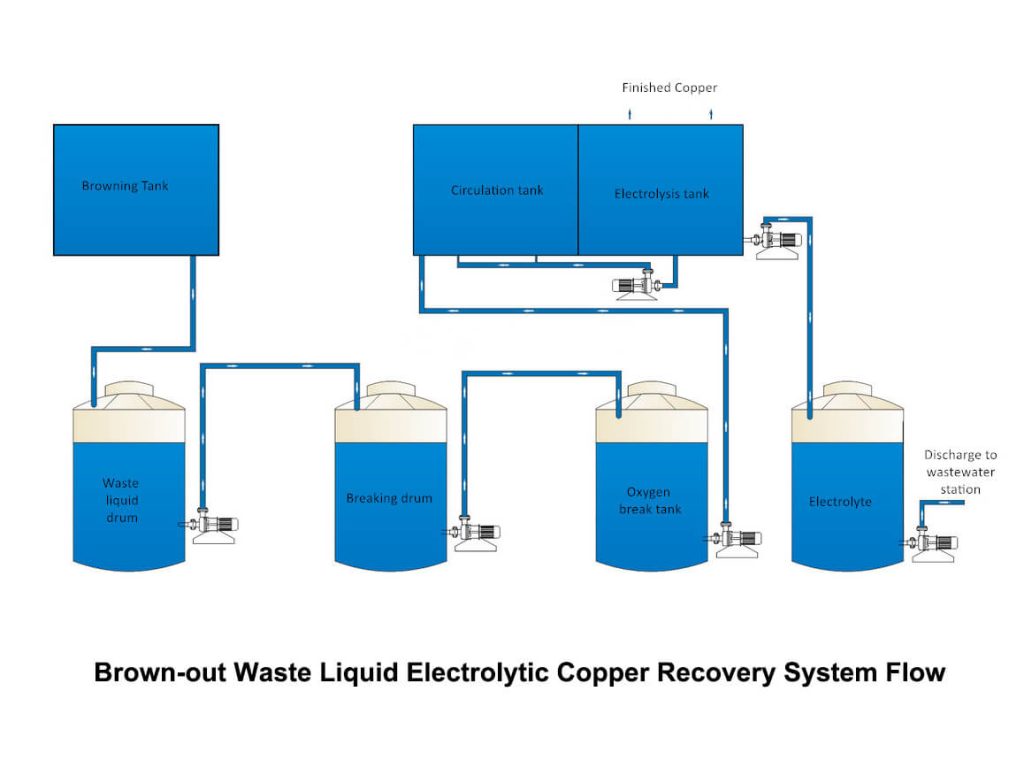

Brownification waste liquid copper extraction equipment will brown liquor through the blowing off, oxidation and electrolysis steps, after pretreatment brown liquor can be directly electrolyzed to get electrolytic copper so that the copper resources of brown liquor can be effectively utilized.

Brownification Waste Liquid Copper Extraction Equipment Overview

The waste liquid resulting from industrial processes, such as metallurgical treatments or chemical processes, can be termed “brownification waste liquid” when it contains high levels of organic pollutants or metals. The brownification waste liquid copper extraction equipment is a specialized machine or system used to extract copper from industrial waste liquids that have undergone a “brownification” process. Brownification waste liquid generally contains high levels of organic materials and dissolved substances, including copper ions, which can be recovered and reused. Brownification waste liquid requires specialized treatment methods to remove impurities, such as chemical precipitation, catalytic reactions, or electrochemical treatment.

This copper extraction equipment/plant from brownification waste liquid is used in industries such as metallurgy, electronics manufacturing, and chemical processing, where copper-containing waste liquids are generated. It helps in recycling valuable metals, reducing waste disposal costs, and mitigating environmental contamination.

For brown chemical waste liquid, the traditional treatment method is to add chemical agents for precipitation, which has high operation costs and low added value. However, the general electrolysis method for brown chemical waste liquid, because brown chemical waste liquid contains a large number of corrosion inhibitors, easy to form a film, electrolysis is easy to form a film on the cathode surface, increases resistance, increases energy consumption, and prevents copper deposition on the cathode surface. In addition, a large number of copper ions exist in complexation form in the waste solution of brownization, which makes it unable to be electrolyzed directly. Because of the difficult electrolytic characteristics of brown chemical liquid, our company has a new type of copper recovery and treatment plant for brownification waster liquid, which can extract copper directly by electrolysis after preprocessing by pretreating brownization waste liquid.

Our Product/System Features

- The purity of cathode copper obtained by electrolysis is higher than 96%.

- The exhaust gas tower is set to automatically add a control device, calibration, and maintenance of the induction probe at regular intervals, to prevent exhaust gas emissions.

- Storage containers are set with double high-level induction alarms to prevent solution leakage.

- The COD value of the stock solution can be reduced by more than 90%.

- The equipment covers a small area and the input cost is low.

Structure/Working Principle

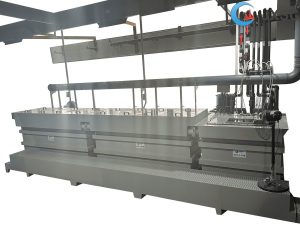

Brownification Waste Liquid Copper Extraction Equipment Structures

The equipment for copper extraction from brownification waste liquid mainly consists of several key components, each playing a vital role in ensuring the efficient and safe extraction of copper from the waste liquid.

1. Waste Liquid Collection and Storage Equipment

Function: Used to collect and store the browning waste liquid generated during the printed circuit board (PCB) manufacturing process.

Equipment Type: Usually made of corrosion-resistant materials such as polypropylene (PP) or polyethylene (PE) tanks, which can withstand the acidic or alkaline chemicals present in the waste liquid.

2. Pretreatment Equipment

Function: Performs preliminary treatment on the waste liquid, such as adjusting the pH and removing large particulate impurities and suspended solids.

Equipment Type

- pH Adjustment System: Using acid or alkali dosing pumps to adjust the pH of the waste liquid to the appropriate range for electrolysis.

- Filtration System: Such as plate and frame filters or bag filters, to remove solid impurities from the waste liquid and prevent them from depositing or obstructing the electrolysis process.

3. Electrolytic Cell

Function: The electrolytic cell is the core component of the system, using electrolysis to reduce copper ions in the waste liquid into metallic copper.

Equipment Type

- Cell Body: Usually made of corrosion-resistant materials such as titanium alloy, PVC, or PP, to resist the acidic or alkaline environment.

- Electrodes:

1. Anode: Typically uses inert electrodes like titanium or lead alloys to stabilize the electrolytic reaction.

2. Cathode: Usually stainless steel or copper plates, where copper ions are reduced and deposited as metallic copper. - Power Supply: A direct current power supply provides the current needed to control the intensity and speed of the electrolysis reaction.

4. Copper Collection Equipment

Function: Collects the metallic copper deposited on the cathode plates in the electrolytic cell.

Equipment Type: Mechanical or manual stripping equipment used to remove the copper layer from the cathode. Common types include:

- Mechanical Stripping Device: Automated machinery that removes copper sheets to improve production efficiency.

- Manual Tools: In smaller systems, hand tools may be used to remove the copper layer.

5. Waste Liquid Circulation and Treatment Equipment

Function: Treats the recovered waste liquid to meet environmental standards or reuse it.

Equipment Type

- Circulation Pump: Pumps the treated waste liquid to the next stage of processing or returns it to the production system for reuse.

- Wastewater Treatment System: Includes neutralization, sedimentation, and filtration units to ensure that discharged wastewater complies with environmental regulations.

6. Automation Control System

Function: Monitors and regulates the entire extraction process, optimizing the efficiency of copper extraction.

Equipment Type: Uses online sensors and controllers to automatically adjust pH, current density, temperature, and waste liquid flow rates to ensure the stability and efficiency of the electrolysis process.

7. Safety and Ventilation System

Function: Ensures the safety of the operators and reduces the emission of harmful gases.

Equipment Type

- Exhaust System: Such as ventilation systems or gas scrubbers, to remove hydrogen gas or other harmful gases produced during electrolysis.

- Safety Equipment: Includes corrosion-resistant coatings and alarm systems to ensure the long-term safe operation of the equipment.

The copper extraction equipment(plant/system) from brownification waste liquid consists mainly of waste liquid collection and storage, pretreatment, electrolytic cells, copper collection equipment, waste liquid treatment systems, and automation control systems. These components work together to achieve an efficient copper recovery process, reducing the environmental impact of waste liquid while enabling the reuse of valuable resources.

Brownification Waste Liquid Copper Extraction Equipment Working Principle

The working principle of the copper extraction equipment for the brownification waste liquid is based on the electrolysis method, in which the copper ions in the brownification waste liquid are reduced to metallic copper through the electrolysis process. Brownification waste liquid through the filter for pre-treatment, filtration of impurities and adsorption of some organic matter, can effectively improve the efficiency of the subsequent process; broken complex device can be similar to a large number of hydroxyl radicals and other free radicals with high oxidation capacity, high oxidation capacity of the free radicals break the film-forming capacity of the brown liquor, so that a large number of stabilized polymer organics dissociated, this step is to destroy the stabilization of the film-forming ability of the brown liquor The function of this step is to destabilize the film-forming ability of the brown liquor, which can facilitate the next step of electrolysis to extract copper. At the same time, the degraded copper ionized waste liquid is passed through the electrolysis tank for copper recovery.

Technical Parameters

Analysis Table for Disposal of Brown Chemical Waste Liquid

| Name | COD(mg/L) | H2O2(mg/L) | Cu2+(mg/L) |

| Waste Liquid Original Liquid | 16850 | 18.8 | 25.5 |

| Waste Liquid After Digestion | 22050 | 1.2 | 24.8 |

| Waste Liquid After Electrolysis | 830 | 0.0 | 2.2 |