Bucket Wheel Sand Washer

Capacity: 15-350 T/H

Feeding Size: ≤10 mm

Process Material: Pebble, Granite, Basalt, Iron ore, Limestone, and more.

Bucket Wheel Sand Washer Overview

The bucket wheel sand washer has adopted advanced technology of high efficient sand washing according to real situations of sand markets to meet the demand for cleaner sands. Building with a more simple structure so it is very convenient to maintain, also more easy to repair.

Sand Washing Machine Types

JXSC supplies two types of sand washing machines: the bucket wheel sand washer, and the spiral type sand washer. They are popularly used in mining and quarrying sites. It usually works with a sand-making machine, a vibrating screen, and a dewatering screen, to prepare clean ore or gravel for further processing.

Advantages

Bucket Wheel Sand Washer Advantages

- Higher sand quality with a lower moisture content.

- Recycled fine size 0.16-3mm sand, lower mud content.

- Compact structure, multiple functions, easy install, convenient maintenance, small occupation area.

- High capacity, after this sand washer 95% sand can be washed.

- Solve sedimentation tank cleaning problem, higher economical profit.

- The sand washing machines whose transmission gear is separated from water and sand to reduce the failure.

Structures & Working Principle

Bucket Wheel Sand Washer Structure

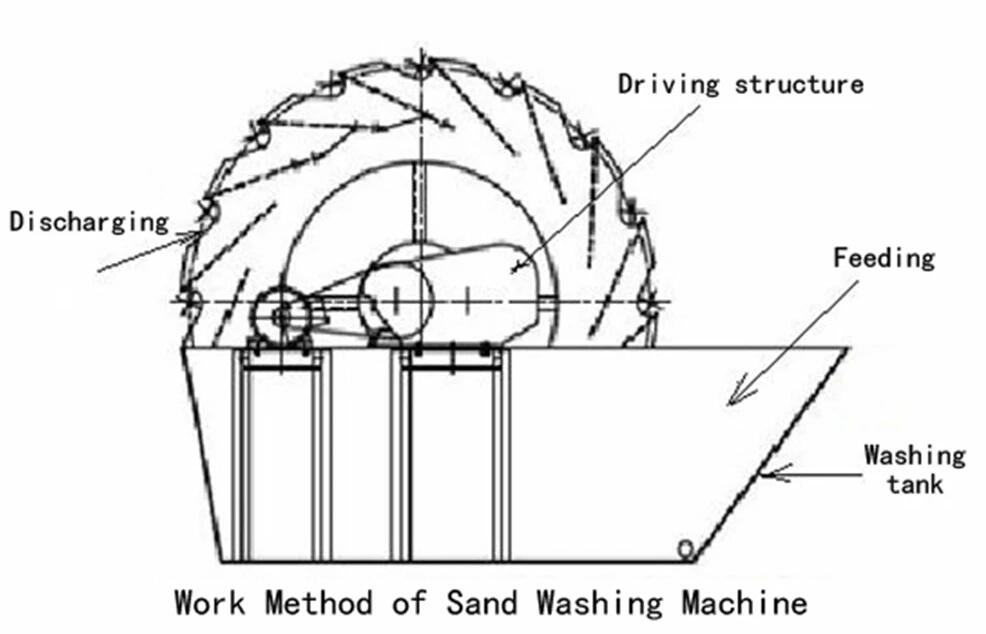

The main parts of a bucket wheel sand washer include feeding, bucket wheel, reducer, motor, washing tank, screen, and discharging.

Bucket Wheel Sand Washer Working Principle

When the sand washing machine is working, the impellors run slowly with the decelerator motor. The sand and stone flow into the washing tank from the feeding launder grinds with each other and roll with the impellor slowly so that the impurities covered in sand are washing out.

Meanwhile, the washing water will take out some waste and impurities from the washing tank. The washed sand and stone are lifted up by the impeller. When it rolls up slowly, the water begins to drop through the meshes and fall back into the washing tank, the water can be fully used.

Finally, the clean sand and stone go out of the washing tank and the washing process is over.

Technical Parameters

| Model | Dia of The Wheel Bucket (mm) | Speed of Rotation (r/min) | Maximum Feeding Size (mm) | Capacity (t/h) | Motor Power(kW) | Overall Dimensions (mm) | Weight(KG) |

| XS22-2 | 2200 | 2.5 | ≤10 | 15-30 | 4 | 3180*1955*2350 | 2260 |

| XS26-2 | 2600 | 2.5 | ≤10 | 20-50 | 5.5 | 3515*2070*2672 | 2500 |

| XS28-3 | 2800 | 1.2 | ≤10 | 50-80 | 11 | 3964*3014*2895 | 3200 |

| XS28-4 | 2800 | 1.17 | ≤10 | 60-100 | 15 | 3964*2137*2895 | 3880 |

| XS30-4 | 3000 | 1.2 | ≤10 | 120-200 | 15 | 4169*3456*3055 | 4350 |

| XS32-3 | 3200 | 1 | ≤10 | 100-160 | 15 | 4340*2760*3349 | 3950 |

| XS32-4 | 3200 | 1.17 | ≤10 | 150-250 | 18.5 | 4346*2198*3345 | 4885 |

| XS36-4 | 3600 | 1 | ≤10 | 200-350 | 37 | 4580*3218*3600 | 7500 |