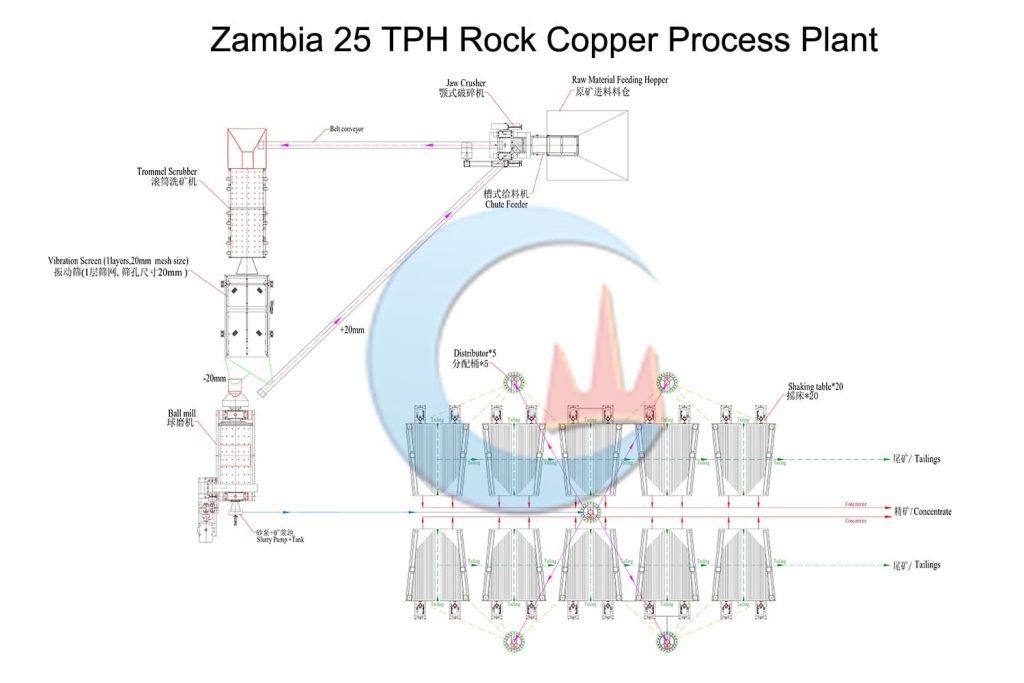

Zambia 25TPH Rock Copper Process Plant

JXSC has provided a 25TPH copper processing plant in Zambia. We design the rock copper process plant flowchart and plant layout drawing according to the mineral ore’s conditions and offer a complete set of plant machines. We also send the engineer to the site to install and debug the machines.

25TPH Rock Copper Process Plant Project Case

Introduction

Minerals: Rock Copper

Capacity: 25TPH

Process: Feeding -> crushing -> washing -> screening -> Grinding -> Gravity Separation

Solutions & Process

Copper Processing Plant

The chute feeder sends the raw material to the jaw crusher for crushing. Use a belt conveyor to send the crushed material to the trommel scrubber. The material from the scrubber goes to the vibration screen(The screen is one layer with 20mm holes). The above 20mm material returns to the jaw crusher for crushing and the -20mm material is sent to the ball mill. The material after ball milling enters the slurry pool. Then use the slurry pump to send them to the distributors, then they enter into the shaking tables. After the shaking table beneficiation, we can get copper concentrate.