Tanzania 10 TPH Alluvial Tin Process Plant

JXSC has provided a successful 10 TPH alluvial tin process plant in Tanzania. We design the separation process plant flowchart & plant layout drawing according to mineral ore’s conditions and offer a complete set of plant machines.

10 TPH Alluvial Tin Process Plant Project Case

Introduction

Minerals: Alluvial tin(without stickly clay)

Capacity: 10 TPH

Process: Feeding -> Washing & Screening -> Gravity Separation

Solutions & Process

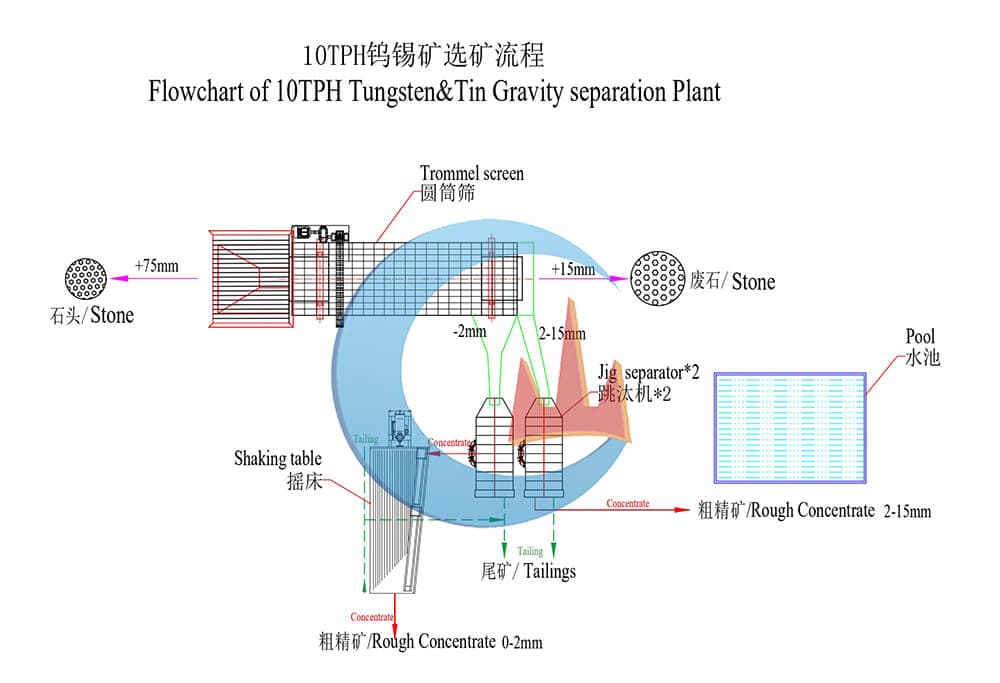

Alluvial Tungsten & Tin Gravity Separation Plant Flowchart

This setup is a 10 tons per hour alluvial tungsten/tin processing plant. It is configured with a vibrating feeder, trommel screen, jig concentrators, shaker tables, belt conveyors, etc. The process is as below:

- The raw ore will be fed into the raw ore hopper above the vibrating feeder by the excavator. The vibrating feeder is designed with a grizzly bar, and bar gap of 75mm, which can feed smaller than 75mm into a Trommel screen.

- The less than 70mm goes to the trommel screen for washing and screening. Later we can get 3 kinds of outputs: less than 2mm, 2-15mm, and larger than 15mm(waste stone).

- After washing by the trommel screen, 2-15mm will go to one set of rough jig concentrators for 1st coarse tin separation, then we can get 2-15mm tin rough concentrate.

- The less than 2 mm goes to another rough jig concentrator for enrichment, and then the concentrate goes to the shaker table for further separation.

- After the shaker table, we can get 0-2mm tin rough concentrate.