Nigeria 300-400TPH Limestone Crushing Plant

JXSC has provided a 300-400TPH limestone crushing plant in Nigeria. We design the limestone crushing plant flowchart and plant layout drawing according to the mineral ore’s conditions and offer a complete set of plant machines.

Limestone Crushing Plant Project Case

Introduction

Minerals: Limestone

Capacity: 300-400TPH

Feeding Size: <850mm

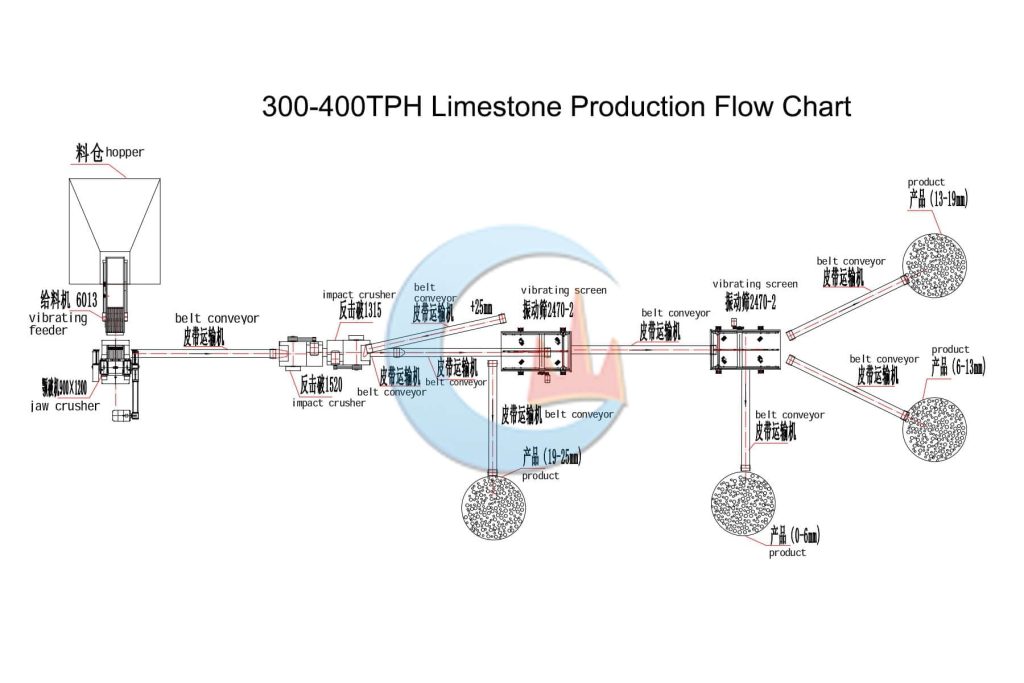

Process: Feeding -> primary crushing -> secondary crushing -> screening

Solutions & Process

Limestone Crushing Process Plant

The excavator unloads the stones into the hopper, and the stone enters the vibrating feeder (model: 6013) from the lower part of the hopper. The vibrating feeder feeds the limestone evenly to the jaw crusher(model:900*1200). The material after being crushed by the jaw crusher is delivered to the first impact crusher(model: 1520). The crushed material from the first impact crusher comes into the second impact crusher(model: 1315) to crush. The output of the impact crushers will be sent to the first vibrating screen(2470-2), we can get 19-25mm and <19mm materials. Send the smaller than 19mm materials to the second vibrating screen. Then we can get the other three output products 0-6mm, 6-13mm, and 13-19mm. Each output will need one separate conveyor belt.