Nigeria 120TPD Lithium Processing Plant

JXSC has provided a turnkey solution for a 120 TPD lithium ore processing plant in Nigeria. We send the engineer to the mine site to check the mine and ore before starting, supply mining project processing consulting at the beginning, design and draw flowcharts, provide complete set processing equipment, and dispatch the engineer to the customer’s mine site for guidance of equipment installation, commissioning, and training workers.

Lithium Processing Plant Project Case

Introduction

Minerals: Spodumene ore, grade is 2%

Capacity: 120 TPD

Feeding Size: <200 mm

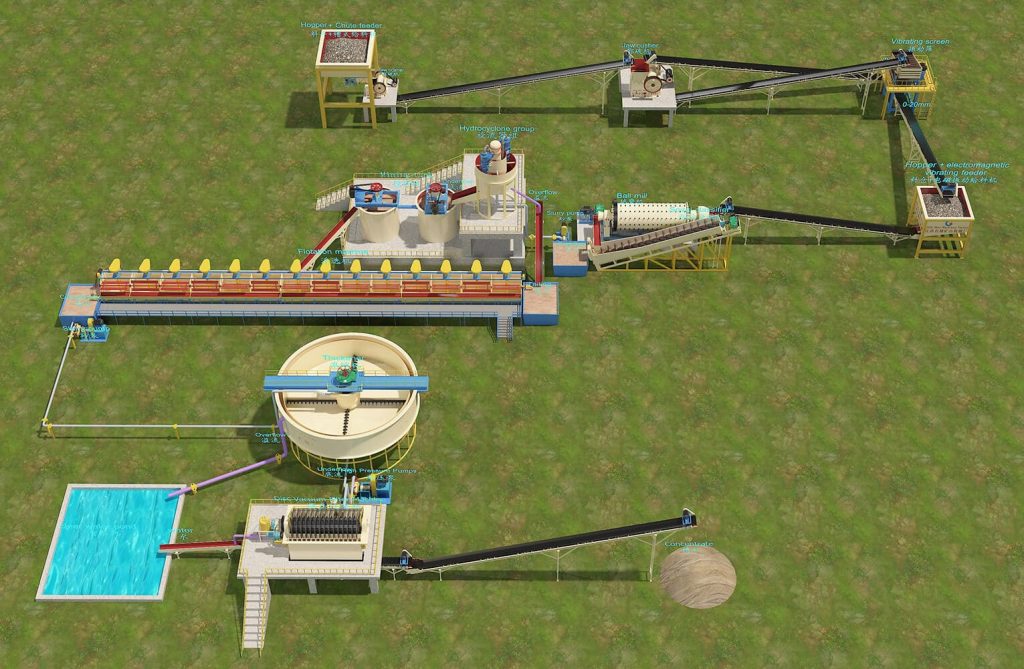

Process: Feeding -> Crushing -> Screening -> Grinding -> Classifying -> Flotation -> Dewatering

Solutions & Process

Lithium Processing Plant

This plant description is as follows:

The wheel loader feeds raw ore to the hopper, through a chute feeder evenly sends ore to a jaw crusher. A belt conveyor sends the materials from the jaw crusher to the fine jaw crusher. The materials from the fine jaw crusher are sent to a vibration screen by a belt conveyor. The vibration screen screening the 20mm size and over 20mm size, over 20mm size will return to fine jaw crusher to crusher again, smaller than 20mm size will go to the next stage.

The materials from the vibration screen will be transferred to a storage bin by belt conveyor, and the materials from the storage bin feeder evenly by the electromagnetic vibration feeder to the ball mill. The ball mill grinds the materials to power and the materials from the ball mill to the spiral classifier. The overflow of the spiral classifier to the next stage, underflow of the spiral classifier back to the ball mill to grinding again.

The materials are from the spiral classifier to hydrocyclone, after hydrocyclone to the mixing tank, and then go to flotation to process spodumene.

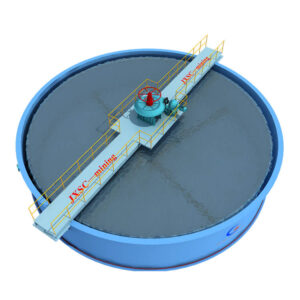

The concentrate of the spodumene will go to the thickener, the overflow from the thickener goes to settling ponds, and then the water can be recycled after precipitation. The underflow from the thickener will go to the disc vacuum filter, and we will get an almost dry spodumene concentrate.